Hornady Full Length Dies User Manual

Full length die instructions, Before using dies, Adjusting the size die

780145

BEFORE USING DIES

Before using your new dies disassemble and carefully clean the inside surface

of the sizing and seating dies (and the expander die if a three-die set.) A rust

preventive oil is applied at the factory to protect the dies during shipping and

must be removed before reloading. Any commercial solvent or cleaner (like

our ONE SHOT Gun Cleaner and Dry Lube) will suffi ce.

Inspect all cartridge cases and discard those with cracks, splits and other

visible defects. Wipe cases clean with a soft cloth to remove grit and other

foreign matter which may scratch the die. Before sizing, lubricate the cases

with one of the case lubes available from Hornady (ONE SHOT Case Lube or

UNIQUE, a hard paste.) No matter the method of lubrication, all rifl e cases

must be lubricated (

Hornady’s Titanium Nitride three-die sets are lube-

free.) We don’t recommend the use of oil-type lubes; they may contaminate the

powder inside the case.

Little or no lube on rifl e cases will result in a stuck case. Over-lubrication

will cause dents in the shoulder, damaging appearance. (If you do get a case

stuck in a die, we can remove the case without damaging the die and return

it to you. Please send the die to our Customer Service Department with $4 for

postage & handling charges.)

ADJUSTING THE SIZE DIE

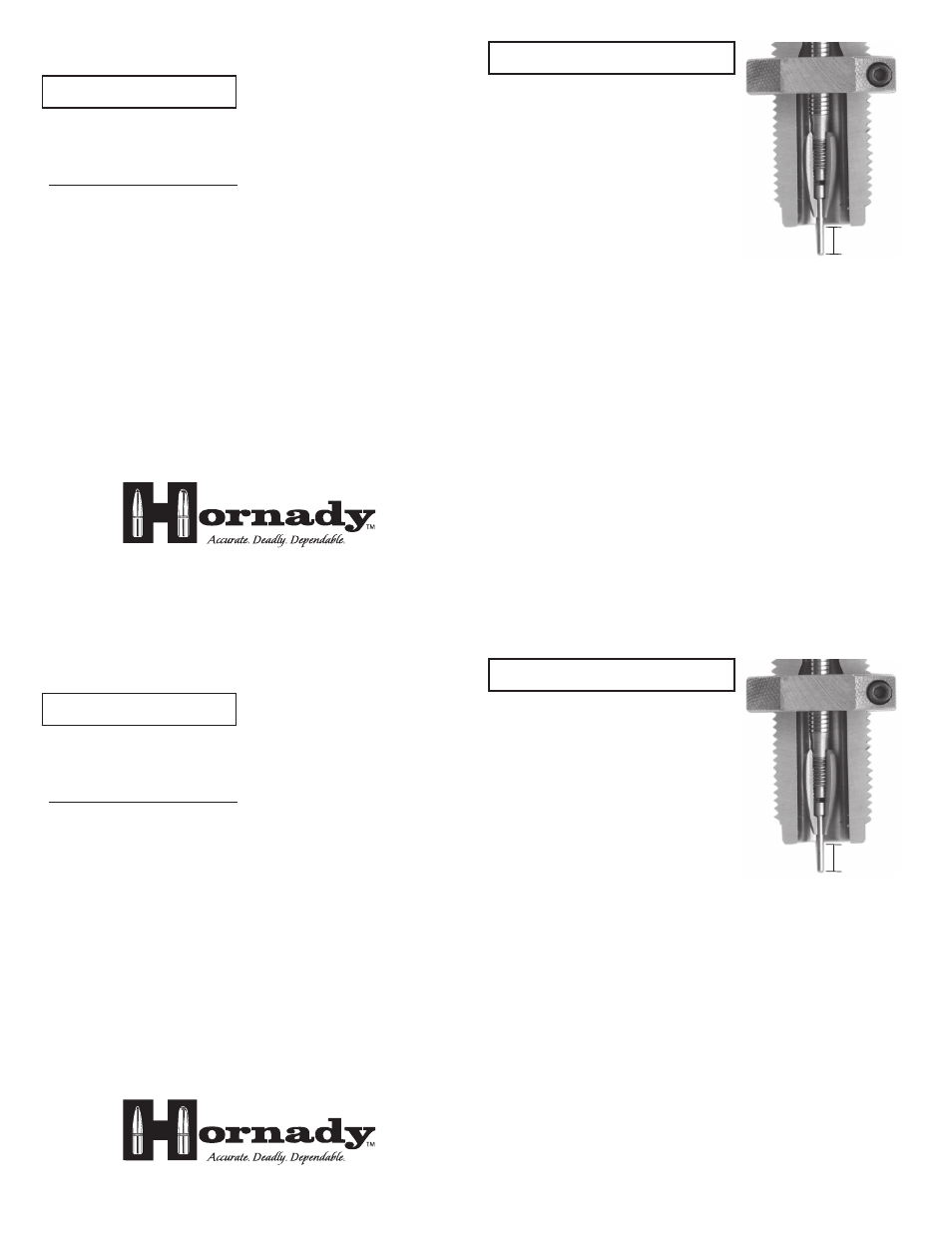

To adjust the expander/decap assembly:

1. Loosen the spindle lock.

2. Adjust the spindle so approximately 3/16"

of the decap pin is below the end of the die

(SEE PHOTO.)

(NOTE: The new Zip Spindle is lightly threaded to

provide a positive no-slip lock. In its free state,

the Zip Spindle can be pulled up and down to make

quick adjustments, or can be threaded for more

precise adjustments.)

3. Make sure the threads on the spindle and collet are engaged and

tighten the spindle lock until the spindle no longer rotates.

4. Verify that the decap pin is only extended 3/16" below die.

(Note: The new Hornady Zip Spindle comes with an easily replaceable headed de-

cap pin. If during use or adjustment, the pin breaks, an extra decap pin has been

provided. Remove the spindle assembly, unthread the expander/retainer, remove

the decap pin head, and replace with the new decap pin.)

To adjust the full-length size die, follow these steps:

1. Raise the press ram to highest position

without camming over.

2. Thread the full-length die into the press until the base touches the

shell holder head.

3. Tighten the lock ring against the press and tighten the set screw with

the allen wrench.

(Note: Firearm action types and chamber dimensions vary causing excess

headspace. To eliminate the headspace, adjust the full-length die upward.)

3/16"

3625 Old Potash Hwy • P.O. Box 1848 • Grand Island, NE 68802

308-382-1390 • www.hornady.com

FULL LENGTH DIE INSTRUCTIONS

780145

BEFORE USING DIES

Before using your new dies disassemble and carefully clean the inside surface

of the sizing and seating dies (and the expander die if a three-die set.) A rust

preventive oil is applied at the factory to protect the dies during shipping and

must be removed before reloading. Any commercial solvent or cleaner (like

our ONE SHOT Gun Cleaner and Dry Lube) will suffi ce.

Inspect all cartridge cases and discard those with cracks, splits and other

visible defects. Wipe cases clean with a soft cloth to remove grit and other

foreign matter which may scratch the die. Before sizing, lubricate the cases

with one of the case lubes available from Hornady (ONE SHOT Case Lube or

UNIQUE, a hard paste.) No matter the method of lubrication, all rifl e cases

must be lubricated (

Hornady’s Titanium Nitride three-die sets are lube-

free.) We don’t recommend the use of oil-type lubes; they may contaminate the

powder inside the case.

Little or no lube on rifl e cases will result in a stuck case. Over-lubrication

will cause dents in the shoulder, damaging appearance. (If you do get a case

stuck in a die, we can remove the case without damaging the die and return

it to you. Please send the die to our Customer Service Department with $4 for

postage & handling charges.)

ADJUSTING THE SIZE DIE

To adjust the expander/decap assembly:

1. Loosen the spindle lock.

2. Adjust the spindle so approximately 3/16"

of the decap pin is below the end of the die

(SEE PHOTO.)

(NOTE: The new Zip Spindle is lightly threaded to

provide a positive no-slip lock. In its free state,

the Zip Spindle can be pulled up and down to make

quick adjustments, or can be threaded for more

precise adjustments.)

3. Make sure the threads on the spindle and collet are engaged and

tighten the spindle lock until the spindle no longer rotates.

4. Verify that the decap pin is only extended 3/16" below die.

(Note: The new Hornady Zip Spindle comes with an easily replaceable headed de-

cap pin. If during use or adjustment, the pin breaks, an extra decap pin has been

provided. Remove the spindle assembly, unthread the expander/retainer, remove

the decap pin head, and replace with the new decap pin.)

To adjust the full-length size die, follow these steps:

1. Raise the press ram to highest position

without camming over.

2. Thread the full-length die into the press until the base touches the

shell holder head.

3. Tighten the lock ring against the press and tighten the set screw with

the allen wrench.

(Note: Firearm action types and chamber dimensions vary causing excess

headspace. To eliminate the headspace, adjust the full-length die upward.)

3/16"

3625 Old Potash Hwy • P.O. Box 1848 • Grand Island, NE 68802

308-382-1390 • www.hornady.com

FULL LENGTH DIE INSTRUCTIONS