Instructions for power case prep center, Lock-n-load, Power case prep center overview – Hornady Lock-N-Load Power Case Prep Center User Manual

Page 3: Product description, General information about case trimming, Safety precautions, No-risk lifetime warranty

Instructions for Power

Case Prep Center:

Secure the Hornady

®

Lock-N-Load

®

Power Case Prep Center

to your reloading bench with four 1/2" diameter bolts, nuts

and washers. Select a bolt length based on the dimensions of

your reloading bench.

Before you start trimming, make sure all cases have been

full-length sized or neck sized with a reloading die.

Check to make sure the power cord is NOT plugged in.

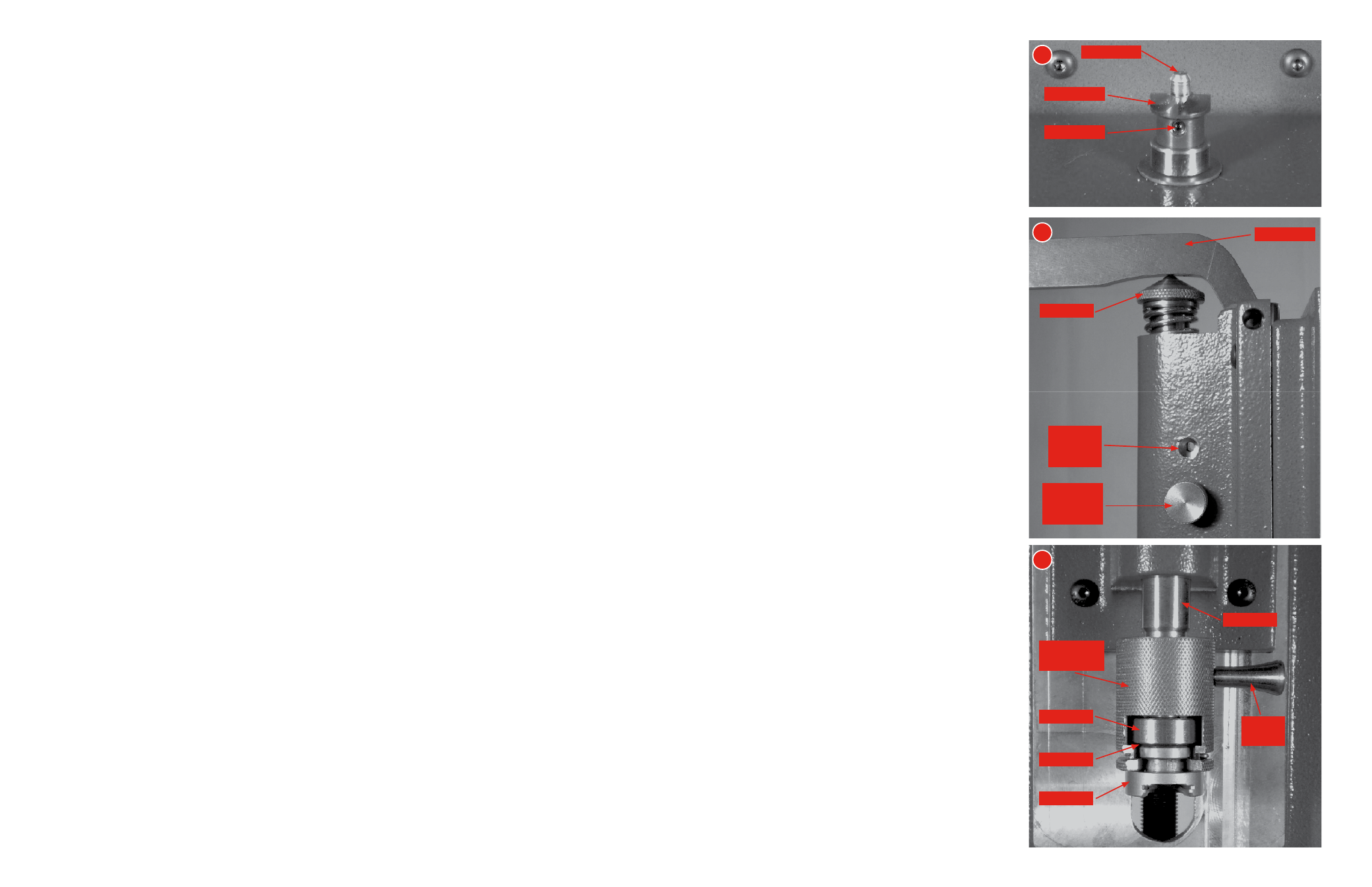

Insert a caliber specific pilot into the cutter, e.g. use trimmer

pilot #1 for .223 Remington. Tighten pilot set screw with the

5/64" hex wrench.

Loosen Main Adjustment Knob on the back of the machine

and turn the Main Adjust Handle counter clockwise so there is

ample room between the Shell Holder and Trimmer Pilot.

When you have installed a caliber specific pilot, focus your

attention on the Position Screw which is located on the

right side of the Spindle Platform. The bottom hole is used

to accommodate short/medium cases and the upper hole is

used for long cases. To check the initial position of the Shell

Holder, insert a case into the Shell Holder Retainer and rotate

it counterclockwise to lock up the case. The slot in the Shell

Holder should be facing the front of the machine. If it is not,

pull down the T-Handle approximately 1/2" and unscrew the

Position Screw. Rotate the Spindle Stop clockwise until the

slot in the Shell Holder faces the front of the machine.

Reinstall the Position Screw in the upper or lower hole.

NOTE: You may have to move the Spindle Stop clockwise or

counterclockwise to realign the Position Screw with the upper

or lower hole. Snug the Position Screw once it’s in position.

To remove the Shell Holder, screw the Shell Holder Retainer

clockwise one turn and pull out the Shell Holder.

Turn the Shell Holder Retainer clockwise one turn, pull out

the Plunger or the Shell Holder and the Plunger. Insert the

Plunger through the center hole of the Shell Holder. Check to

make sure the O-Ring is between the Plunger and the Shell

Holder.

Replace the Shell Holder and Plunger and screw the Shell

Holder Retainer counterclockwise one turn.

Guide a case specific Shell Holder into the Shell Holder

Retainer until it snaps into place, e.g. use Hornady Shell

Holder #16 for .223 Remington.

Turn the Cam-Lock

™

handle clockwise until the Plunger is

flush with base of Shell Holder. Insert a case into the Shell

Holder and turn the Cam-Lock

™

handle counterclockwise.

This will lock the case in the Shell Holder.

NOTE: Check to make sure the slot in the Shell Holder

Retainer is facing the front of the machine when you lock a

case up in the Shell Holder.

1

2

3

1

2

3

Trimmer Pilot

Cutting Unit

Spindle Stop

Plunger

Spindle

Shell Holder

O-Ring

Short/Medium

Case Length

Position

Set Screw

T-Handle Arm

Long

Case Length

Position

Spindle Holder

Retainer

Cam-Lock

Handle

Lock-N-Load

®

Power Case Prep Center

OVERVIEW

Thank you for purchasing the Hornady

®

Lock-N-Load

®

Power Case Prep Center. Please read these instructions before using this machine. If

you have any questions about this machine, contact us at 1-800-338-3220.

Product Description:

The Hornady

®

Lock-N-Load

®

Power Case Prep Center features a powered Case Trimmer and six work stations for the following reloading tools:

Chamfer Tool, Deburring Tool, large and small Primer Pocket Cleaning Heads and caliber specific case neck brushes. The Power Case Prep Center

may also be used to deburr flash holes and uniform/ream primer pockets with optional accessories which are sold separately.

The Cam-Lock

™

feature on the Hornady

®

Lock-N-Load

®

Power Case Prep Center locks the case in a removable Shell Holder for precise trimming.

The Lock-N-Load

®

Power Case Prep Center will only work with Hornady Shell Holders (Hornady Shell Holders are sold separately). The Power Case

Prep Center comes with a 5/64” hex wrench and seven interchangeable pilots to accommodate .22 cal, 6mm, .270 cal, 7mm, .30 cal, .38 cal

and .45 caliber cartridges. Other pilots are available. Caliber specific pilots are used to align the case mouth on the cutting unit. The Hornady

®

Lock-N-Load

®

Power Case Prep Center is engineered to help you significantly improve the efficiency of your reloading process by combining several

essential case prep tools into one unit.

General Information About Case Trimming:

Repeated firing and reloading results in the brass of a case flowing towards the case mouth. Reloaded cases grow in length because of these

actions. When a case exceeds its maximum case length, it may contact the throat of a firearm. If this happens, the case will not release the bullet

properly upon firing and chamber pressure will subsequently increase. Whenever a case grows longer than its maximum specified length it must

be trimmed back to a length near the minimum for that caliber. Trim and maximum case length specifications for modern cartridges are published

in the

Hornady Handbook of Cartridge Reloading. (Refer to this handbook for case trim specifications and other case prep topics.)

Safety Precautions:

The Hornady

®

Lock-N-Load

®

Power Case Prep Center has been engineered with your safety in mind. The likelihood of an injury or property damage

is reduced when these safety precautions are followed.

• Become thoroughly familiar with the machine by studying these instructions.

• Leave the machine unplugged until you are ready to prep cases and have read these instructions.

• Do not work on or near damp or wet surfaces.

• Plug power cord into a properly grounded outlet.

• Wear eye protection when operating the Power Case Prep Center.

• Do not use this machine if you’re rushed for time and don’t take shortcuts by attempting to bypass any of these instructions.

The Hornady

®

Lock-N-Load

®

Power Case Prep Center has an in-line fuse to protect the motor from damage when the cutter is under too much load.

If you try to trim off more than .050” at a time really fast you may put too much load on the motor which will blow the fuse. The fuse is a 1¼ amp,

¼” x 1¼” fast acting glass fuse. You can purchase these at most automotive or electronic stores. Under normal use, you should never have to

replace the fuse.

NEVER USE A FUSE LARGER THAN 1¼ AMP.

No-Risk Lifetime Warranty

All Hornady reloading tools and accessories are warranted against material defects and workmanship for the life of the product.

Simply stated – if it breaks, we’ll repair it or replace it at no charge (at Hornady Manufacturing Company’s option).

Hornady reloading tools and accessories are warranted against defective materials and workmanship only. This warranty is void if the product

(1) has been damaged by accident or unreasonable use, neglect, improper service or other causes not arising out of defects in material

or workmanship; or (2) has been altered or repairs have been made or attempted by other than authorized factory personnel; (3) is used

commercially; or (4) has been altered or defaced in any way.

This warranty supersedes all other warranties for Hornady products either written or oral. No other warranty is expressed or implied.

- 5 -

- 4 -