High voltage ignition cable igniter, Fig. 13, Fig. 14 – L.B. White I-40 Infraconic Spark Ignition User Manual

Page 16: Fig. 15

15

1. Remove the control box cover.

2. Disconnect the igniion cable from ignition module.

3. Loosen the water tight connector nut. See Fig. 12.

Pull the ignition lead through this connection.

4. Disconnect the high voltage ignition cable from the

ignitor. See Fig. 13.

5. Remove the connector nut from the ignition cable.

This nut will be used on the replacement ignition

cable.

6. Ensure cable is positioned away from the venturi tube

and its boot is covering the ignitor terminal.

FIG. 13

DISCONNECT FROM

IGNITOR LEAD

LOOSEN NUT

DISCONNECT

NITOR LEAD FROM

CONTROL BOX

B

A

C

1

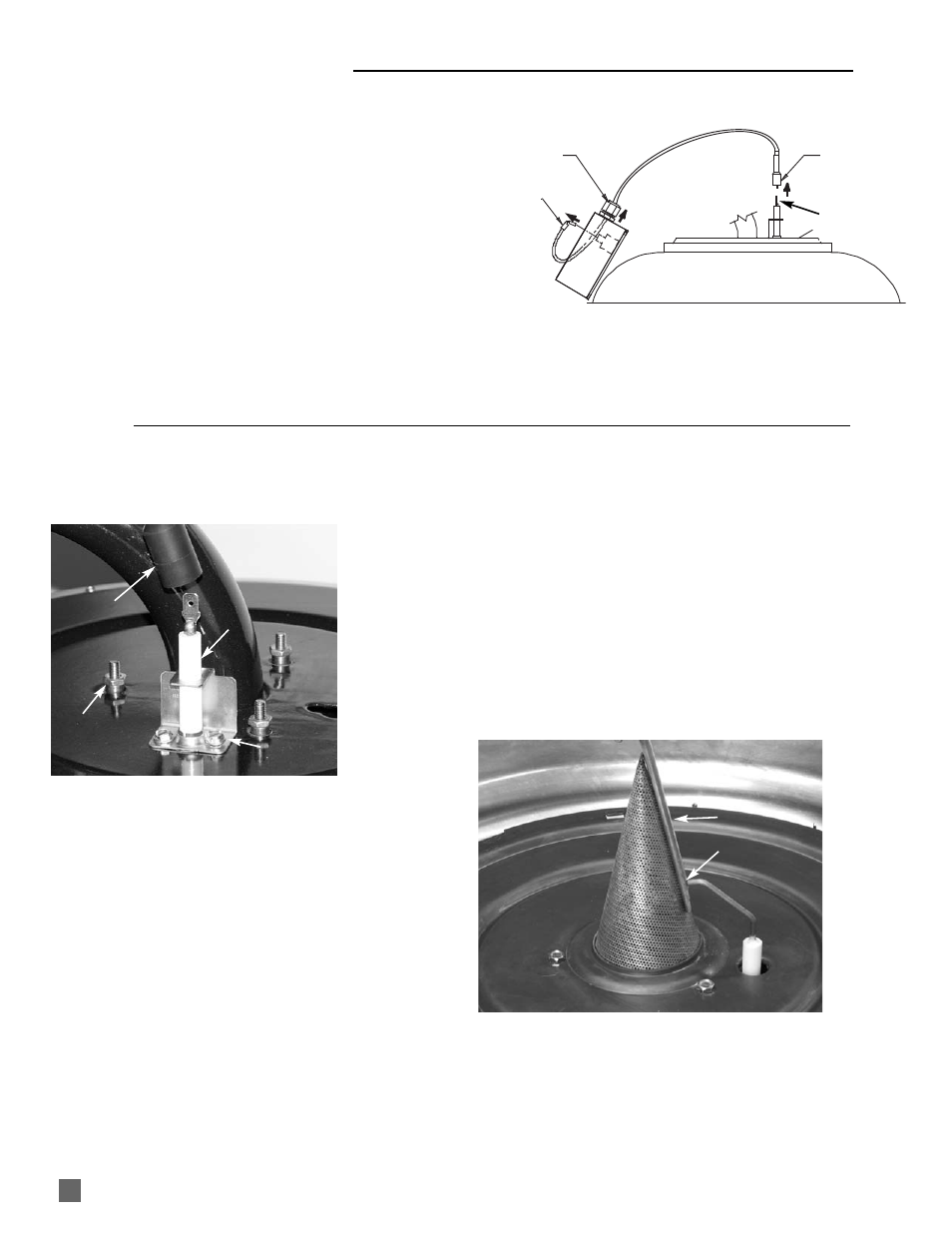

Disconnect the ignition cable from the ignitor. Remove

ignitor mounting screws. See Fig. 14.

Fig. 14

2. Remove the igniter from the heater. Clean the ignitor

rod with steel wool or emery cloth.

3. The rod and its insulating ceramic body must be rigid

within its mounting bracket. If either are capable of

movement, the igniter will not be properly positioned to

the combustion cone. The igniter must then be

replaced.

Adjusting Ignitor Gap

Gap may need to be adjusted if spark is weak or non-existent

after the ignitor has been either cleaned or replaced. Refer to

the following instructions.

a. Ensure the three burner plate nuts are snuggly

tightened. See Fig 14.

b. To properly check gap, insert gapping tool part # 23967

at opening between inner and outer combustion cone

tips. Position the thickest section of tool between ignitor

tip and inner cone. Adjust gap if needed. See Fig. 15,

shown without outer cone.

Fig. 15

c. If necessary, adjust the gap:

-- loosen igniter mounting screws.

-- reposition the igniter until the gap is

within the proper tolerances.

d. Tighten the igniter mounting screws, and remove gauge.

HIGH VOLTAGE IGNITION CABLE

IGNITER

IGNITOR

TERMINAL

DISCONNECT

CABLE FROM

IGNITION

CONTROL

LOOSEN WATER

TIGHT NUT

DISCONNECT CABLE

FROM IGNITOR

TERMINAL

NUTS

IGNITER

IGNITER

SCREWS

IGNITION CABLE

.175

TOOL