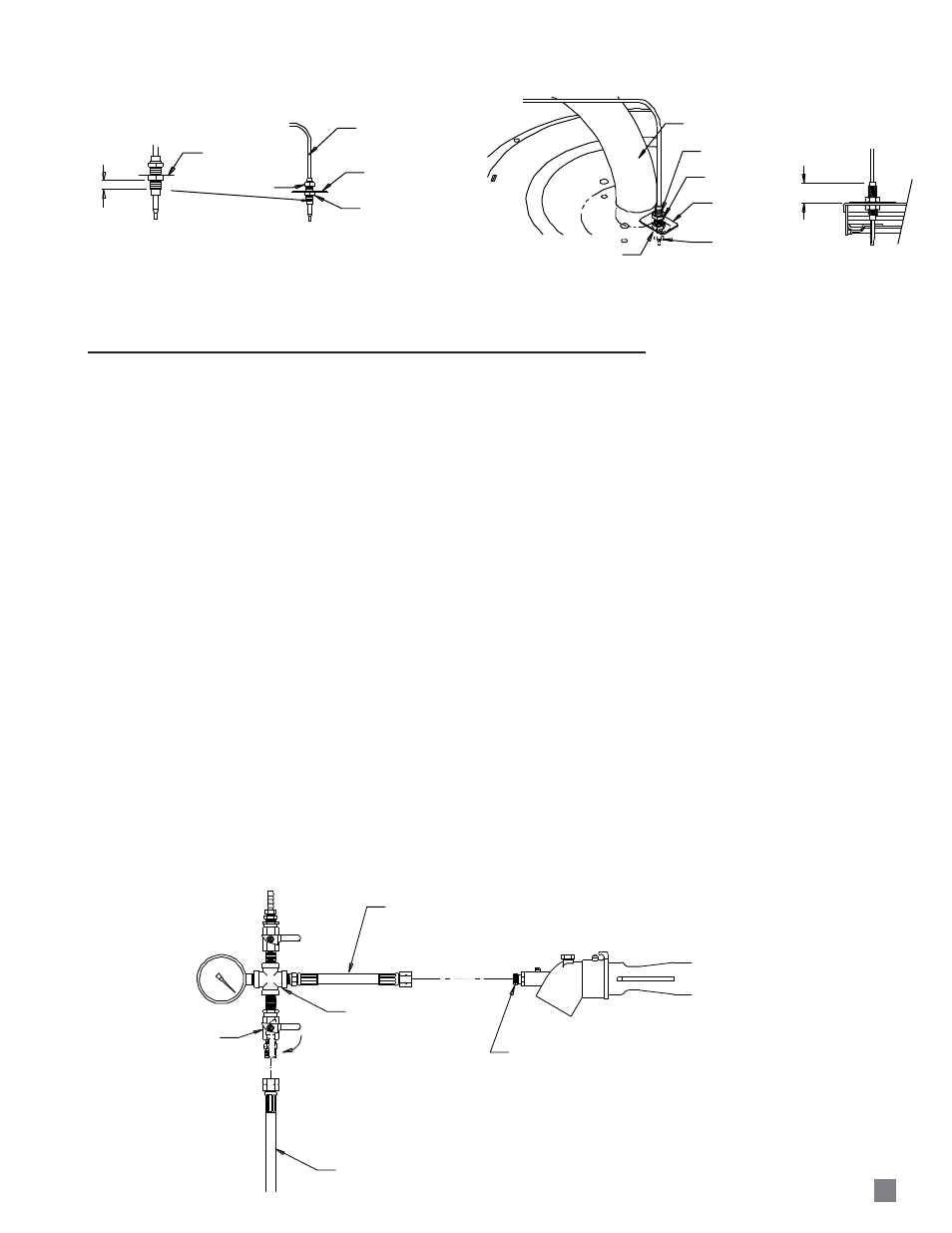

Gas pressure checks, Fig. 24, Fig. 22 fig. 23 – L.B. White I-34 Infraconic Pilot Ignition User Manual

Page 19

LEAD END OF THERMOCOUPLE

THERMOFUSE

5/16"

COVER

UPPER NUT

THERMOCOUPLE

LEAD

COVER

LOWER NUT

TEST KIT HOSE

FUEL SUPPLY VALVE

(OPEN THIS VALVE TO

USE PRESSURE GAUGE)

GAS SUPPLY HOSE

GAS INLET OF HEATER

PRESSURE GAUGE KIT

20736

OPEN

FIG. 24

A.

Preparation

1.

Obtain an L.B. White pressure gauge test kit - Part

No. 20736.

2.

Close the fuel supply valve to the heater.

3.

Brush or blow off any dust and dirt on or in the

vicinity of the gas control valve.

4.

Disconnect the gas hose from the heater.

B.

Gauge Installation

1.

Connect the pressure test kit between the heater and

its gas supply hose as shown in Fig. 24. Insure both

gas shut-off valves on the test kit are in the closed

position when connecting the kit to the heater and

gas supply.

2.

Open the main fuel supply valve to the heater.

3.

Open only the gas shut-off on the test kit to which the

main gas supply hose is connected. Light the heater.

C.

Reading Pressures

1.

Set building temperature control to call for heat.

2.

Re a d t h e p r e s s u r e g a u g e w h e n t h e h e a te r i s

operating at full heat output and also when the pilot

only is lit.

3.

Does the reading on the gauge of the test kit agree

with that specified on the dataplate? If so, then no

further checking or adjustment is required. Proceed

to Section D.

4.

If the pressure does not agree with that specified on

the dataplate, the regulators controlling gas pressure

to the heaters requires adjustment.

D.

Completion

1.

Once gas pressure has been confirmed and/or

properly set, close the fuel supply valve to the heater

and allow the heater to burn off any gas remaining in

the gas supply line.

2.

Remove the gauge kit and connect gas hose to

heater.

3.

Open the main fuel supply valves to the heater and

light the heater.

4.

Set building control to desired temperature.

GAS PRESSURE CHECKS

19

(TYPICAL)

FIG. 22

FIG. 23

THERMOCOUPLE INSTALLED

INJECTOR TUBE

THERMOCOUPLE BODY

RETAINING NUT

COVER

THERMOCOUPLE TIP

LOCATION HOLE IN PLATE

1/2 IN TO 9/16 IN

FINISHED

THERMOCOUPLE

POSITION