Maintenance, Operation...continued – Steele Products SP-PB125 User Manual

Page 7

Cutting workpiece (Fig. 11)

1.Set the angle plate (1) to the desired cutting

angle.

2.Make sure the workpiece lies flat on the cut-

off saw table.

3.Use the vise (2) to secure the workpiece to

the table.

4.Squeeze the trigger switch.

5.After the motor reaches full speed, lower the

disc into the centre of the workpiece.

6.Using a smooth, firm, and gentle downward

motion, make a clean cut through the

workpiece. Do not allow the disc to bump or jump when making contact with the damage both the

workpiece and the disc.

7.Keep consistent pressure when coming to the bottom of the cut to avoid forming a heavy burr and

overheating the workpiece.

8.Raise the disc completely from the workpiece before releasing the trigger switch and allow the

motor to stop before removing the workpiece.

Note: Along workpiece should be supported on both ends with blocks of a non-flammable material

so that the workpiece is level with the cut-off saw table.

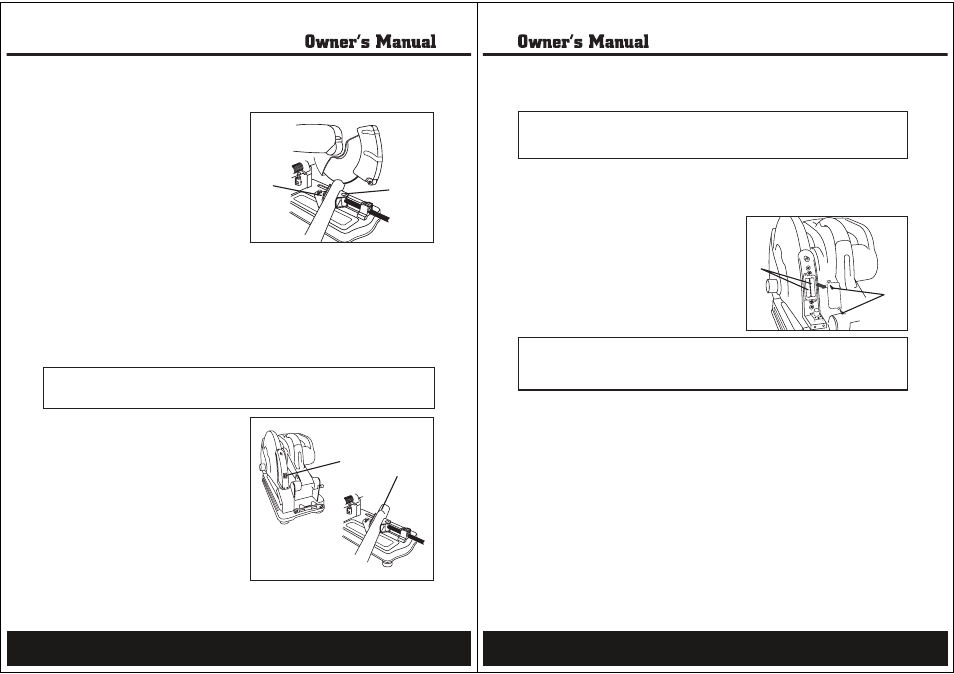

Using the laser line (Fig. 12)

1.Secure the workpiece in the vise clamp.

2.Turn the laser switch (1) to the ON position.

3.Check the location of the laser line on the

workpiece. Move the workpiece (2) , if needed.

Fig. 11

1

2

1

2

Fig. 12

WARNING: DO NOT STARE DIRECTLY AT THE LASER BEAM! A HAZARD MAYEXIST IF YOU

DELIBERATELY STARE INTO THE BEAM, PLEASE OBSERVE ALL SAFETY RULES.

Operation...continued

12

Brush inspection and replacement

Replace both carbon brushes when either has less than 1/4" of carbon remaining. To inspect or

replace, unplug the cut-off saw, remove the carbon brush cap on the side of the motor housing, and

pull out the brush (Note: the cap is spring-loaded). Repeat the steps on the other side. To reassemble,

reverse the procedure.

Replace the laser module batteries (Fig. 13)

1.Remove the 3 screws that secure the laser

module cover to the housing. Remove the cover,

taking care not to damage the wires connected to

the laser switch.

2.Remove the 2 screws (1) that secure the battery

cover to the battery case. Remove the battery

cover.

3.Replace both "AAA" batteries (2).

Lubrication

STEELE

®

tools are properly lubricated at the factory and are ready to use. When necessary, lubricate

only those parts that pivot or move with a dry silicone spray. Lubricating motor bearings and other

internal parts should be done only by qualified service technicians.

General maintenance

Before each use, inspect the guards, switches, power cord, and extension cord. Check for

loose screws, jamming, improper mounting, broken parts, and any other condition that may

affect the safe operation of the cut-off saw. If an unusual operating noise or vibration occurs,

turn the cut-off saw OFF and immediately correct the problem before using the cut-off saw

again.

Cleaning

Clean dust and debris from vents, tabletop, and vise screw. Use a dry, clean rag to clean all areas of

the cut-off saw. Never use solvents or other harsh chemicals for cleaning as they are harmful to

plastic and other insulated parts. Petroleum-based products, brake fluid,thinners and ammonia

detergents will also permanently damage the cut-off saw.

WARNING:TO AVOID INJURY FROM UNEXPECTED START-UP OR ELECTRICAL SHOCK, UNPLUG

THE POWER CORD BEFORE ATTEMPTING INSPECTION OR MAINTENANCE. DO NOT USE

A DAMAGED CUT-OFF SAW.

WARNING: NEVER USE FLAMMABLE OR COMBUSTIBLE SOLVENTS AROUND THIS CUT-OFF

SAW.WHEN SERVICING, USE ONLY IDENTICAL STEELE

®

REPLACEMENT PARTS. USE OF ANY

OTHER PARTS MAY CREATE A HAZARD OR CAUSE PRODUCT FAILURE.

Fig. 13

1

2

Maintenance

13