Operation, Operation...continued – Steele Products SP-PB125 User Manual

Page 6

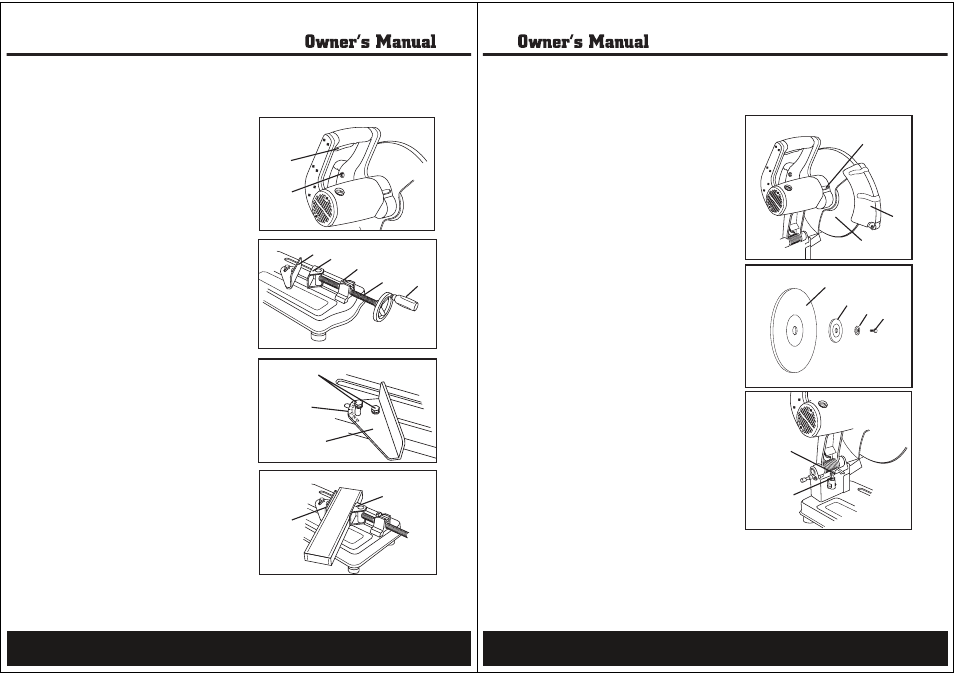

ON/OFF trigger switch (Fig. 4)

To start the cut-off saw, squeeze the trigger

switch (1). To stop the cut-off saw, release the

trigger switch.

Reset switch (Fig. 4)

If the cut-off saw does not start when the trigger

switch is depressed, press the reset switch.(2)

Squeeze the trigger switch to start.

Swivelling vise clamp assembly with

quick-release latch (Fig. 5)

Always secure the workpiece between the angle

plate and the vise pressure plate when cutting.

1.Place the workpiece between the angle

plate (1) and the vise pressure plate (2).

2.Push the vise screw (3) toward the angle

plate and turn the vise wheel (4) clockwise to secure.

To release, turn the wheel counter-clockwise two

turns,raise the quick-release latch (5) and pull the

vise screw towards you.

Angle plate (Fig. 6 and 7)

The angle plate can be moved forward,backward, or

rotated for angle cutting.

1.To set a cutting angle, loosen the two bolts (1) and

rotate the angle plate (3) up to 45˚ right or 45˚ left.

Align the index (2) with the red line on the saw

table. Retighten the bolts.

2.Always centre the workpiece over the table slot-web

to maximize cutting depths.Move the vise pressure

plate (4) toward the angle plate (3).Tighten angle

plate bolts (2)and vise pressure plate (4).

3.To move the angle plate (3), remove the two

bolts (1) and washers. Move the angle plate to

the desired position and align the angle plate

with the threaded holes on the saw base.Insert the

two bolts and washers and tighten to secure the

angle plate to the table.

Fig. 4

Fig. 5

Fig. 6

Fig. 7

1

2

1

2

5

3

4

2

1

3

3

4

Operation

10

Installation and removal of metal cutting disc

(Fig.8 and 9)

1.Unplug the cut-off saw.

2.Push the arbor lock lever (1) towards the metal

cutting disc (2) and slowly turn the disc (either

direction) until the disc locks. (Fig. 8)

3.Push back the lower blade guard (3) and loosen

the hex bolt (6) in the centre of the disc using

the wrench. Remove the bolt (6), washeraq (5),

flange (4) , and disc (2) . (Fig. 9).

4.To install a new metal cutting disc, reverse the

process in step 3. Do not overtighten the bolt.

5.Make sure all guards are in place and the disc

rotates freely.

6.Adjust the depth stop bolt (Fig. 10). Return the

wrench to the storage slot.

7.Plug in the cut-off saw.

8.Run the cut-off saw and check to make sure the

disc is in good condition. Always stand to one

side when turning on the cut-off saw. When

testing a new disc, run the the cut-off saw for

3minutes. When testing an existing disc, run the

cut-off saw for 1minute.

Adjusting the cutting depth (Fig. 10)

The diameter of the metal cutting disc decreases

with use. The depth stop bolt should be adjusted

periodically to prevent the disc from cutting the

work surface below the cut-off saw table.

1.Loosen the lock nut (1).

2.Turn the stop bolt (2) to set the downward travel

of the disc.

3.Lower the saw to check the depth.

4.Repeat steps 2 and 3 until the downward travel

of the disc is at the desired level.

5.Tighten the lock nut (1) to secure the cutting

depth assembly.

Fig. 8

Fig. 9

Fig. 10

2

4

5

6

1

1

2

2

3

Operation...continued

11