4 installing the air locker, Bench testing the air locker – ARB RD137 User Manual

Page 23

4 Installing the Air Locker

21

NOTE : Excessive tightening of the center compression nut is

not necessary to form a good seal around the tube

and may damage the O-ring, the seal housing tube, or

the threads of the compression nut.

NOTE : Make sure the seal housing tube is all of the way into

the center compression nut while you are tightening

it.

c Again check that no part of the seal housing tube comes in contact

with the moving differential components. 10mm [3/8”] should be

considered adequate clearance. Gently bend the tube away from

moving parts if necessary.

4.11

Bench Testing the Air Locker

c To test the Air Locker; when 620kPa [90 PSI] shop air is applied to

the seal housing tube, the Air Locker should engage.

c Check all fittings and the seal housing for air leaks.

c Rotate the differential carrier by turning the pinion flange whilst

applying air pressure.

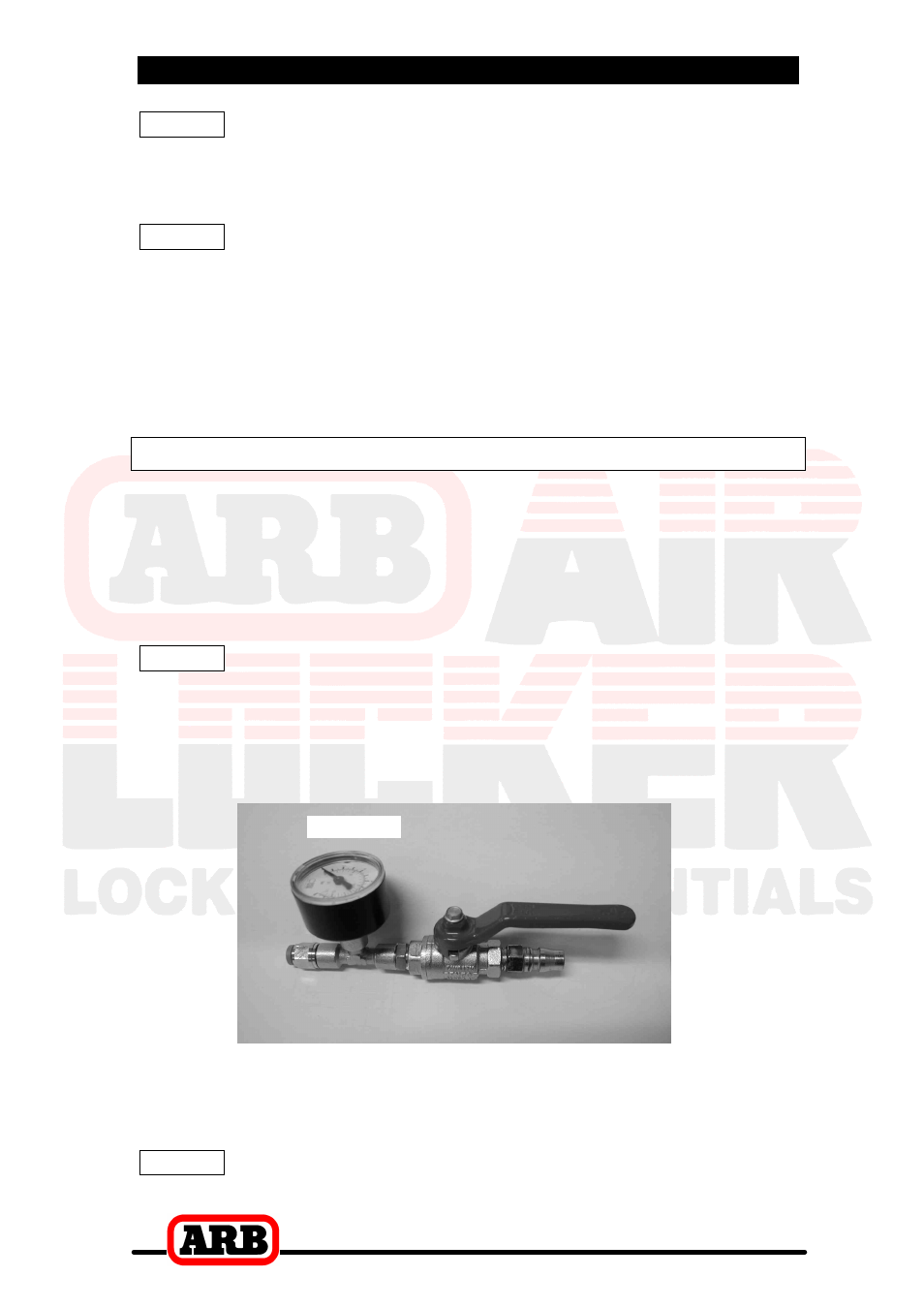

NOTE : An accurate way to test for air leaks is to fit a shut-off

valve to an air pressure gauge (ARB part # ALTG01).

Once 620 KPA [90 PSI] is reached close the valve,

disconnect the air hose, and watch to see if there is any

drop in pressure. If so, this will indicate an air leak.

(Fig.15.)

Figure 15.

c If a leak is found to be present, spray a soap and water mixture

onto the bulkhead air fitting. Bubbles should appear at any leak

points.

NOTE : Do not spray this soapy mixture inside the differential.