Maintenance procedures – Fluid Management NSC50 Harbil User Manual

Page 13

NSC50 Operating & Instruction Manual

13

MAINTENANCE PROCEDURES

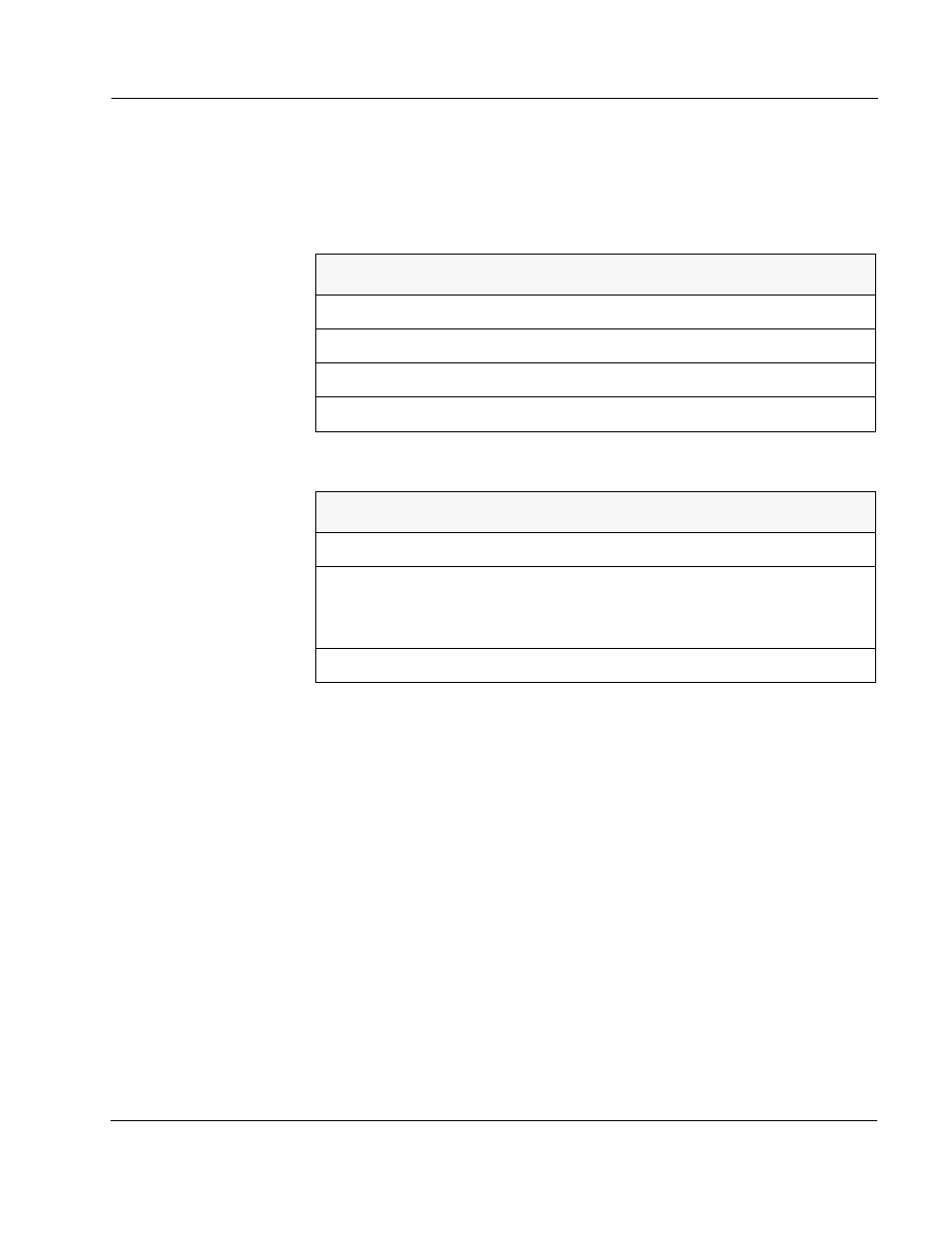

MAINTENANCE

PROCEDURES

To ensure safe, dependable operation of the equipment, follow the

maintenance schedule detailed below:

DAILY

Cleaning & Filling:

• Agitate colorants every morning for five (5) to ten (10) minites.

• Clean nozzles & outside cabinet surfaces with soap and water.

• Check canisters and fill as required.

WEEKLY

Cleaning & Nozzle Maintenance:

• Dispense a full measure of any colorant that has not been used

during the previous week. Dispense into a clean container and

return to the appropriate canister.

• Clean all accessible inside surfaces with soap and water.

GENERAL MAINTENANCE

If a nozzle becomes clogged, the obstruction can generally be cleared by

inserting a paper clip or similar object in the valve opening. Before inserting

such a device, open the valve by pulling the valve lever down and holding

while clearing the opening. BE SURE THAT THE VALVE IS OPENED,

AND STAYS OPEN WHILE CLEANING IN THIS WAY. IF THE

VALVE CLOSES AT ANY TIME DURING THIS OPERATION, THE

VALVE COULD BE DAMAGED. If colorant leaks develop at the top of

the pump, or if colorant can be observed on the pump piston rod, the pump

assembly must be repaired. The Pump Repair Kit (P/N 4223212) can be

purchased from the Fluid Management Customer Service Department. A

colorant leak at the bottom of the pump assembly generally indicates that the

pump assembly has been damaged. In this case, the valve assembly must be

replaced with either the Viton Valve Repair Kit (P/N 4231002) or the

Thiokol Repair Kit (P/N 4231011).