Torque specifications – Blizzard Entertainment Blizzard Power Plow 810SS User Manual

Page 7

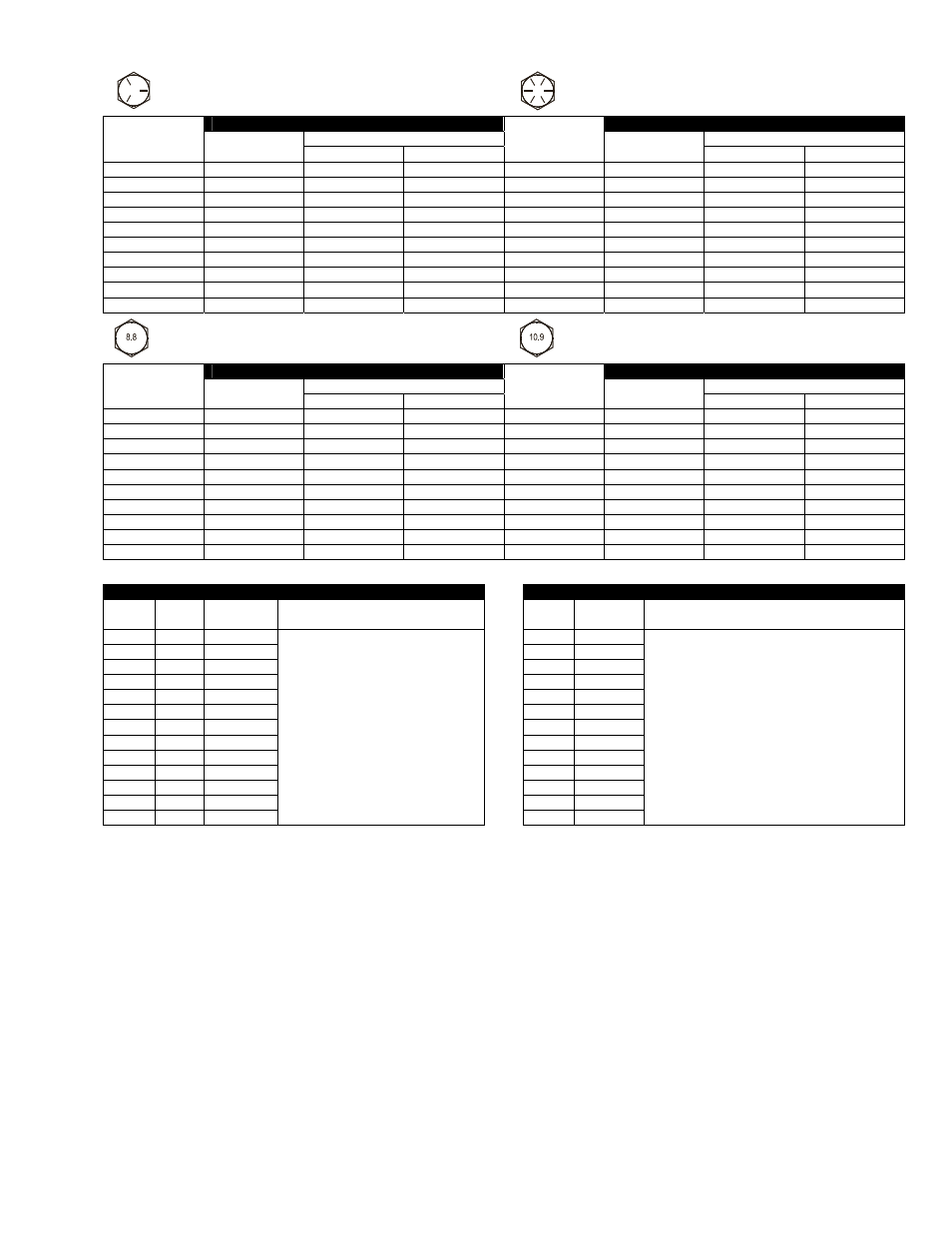

TORQUE SPECIFICATIONS

7

64060 (2005-810&8611SkidSteer).doc

Grade Identification Marking for J429-Grade 5 Bolt

Grade Identification Marking for J429-Grade 8 Bolt

SAE J429 – Grade 5

SAE J429 – Grade 8

Tightening Torque

Tightening Torque

Nominal

Thread Size

Clamp Loads

(lbs)

“Lubricated” “Dry”

Nominal

Thread Size

Clamp Loads

(lbs)

“Lubricated” “Dry”

1/4-20

2,000

6 ft-lbs

8 ft-lbs

1/4-20

2,850

9 ft-lbs

12 ft-lbs

5/16-18

3,350

13 ft-lbs

18 ft-lbs

5/16-18

4,700

18 ft-lbs

25 ft-lbs

3/8-16

4,950

23 ft-lbs

31 ft-lbs

3/8-16

6,950

32 ft-lbs

44 ft-lbs

7/16-14

6,800

37 ft-lbs

50 ft-lbs

7/16-14

9,600

53 ft-lbs

70 ft-lbs

1/2-13

9,050

57 ft-lbs

75 ft-lbs

1/2-13

12,800

80 ft-lbs

107 ft-lbs

9/16-12

11,600

82 ft-lbs

109 ft-lbs

9/16-12

16,400

115 ft-lbs

154 ft-lbs

5/8-11

14,500

113 ft-lbs

151 ft-lbs

5/8-11

20,300

159 ft-lbs

211 ft-lbs

3/4-10

21,300

200 ft-lbs

266 ft-lbs

3/4-10

30,100

282 ft-lbs

376 ft-lbs

7/8-9

29,435

321 ft-lbs

430 ft-lbs

7/8-9

41,550

454 ft-lbs

606 ft-lbs

1-8

38,600

482 ft-lbs

640 ft-lbs

1-8

54,540

680 ft-lbs

900 ft-lbs

Grade Identification Marking for Metric-Grade 8.8 Bolt

Grade Identification Marking for Metric-Grade 10.9 Bolt

Metric Class 8.8

Metric Class 10.9

Tightening Torque

Tightening Torque

Diameter

(mm)

Clamp Loads

(Pounds)

“Lubricated” “Dry”

Diameter

(mm)

Clamp Loads

(Pounds)

“Lubricated” “Dry”

5

1,389

3 ft-lbs

5 ft-lbs

5

1,987

5 ft-lbs

7 ft-lbs

6

1,965

6 ft-lbs

8 ft-lbs

6

2,812

8 ft-lbs

11 ft-lbs

7

2,826

10 ft-lbs

13 ft-lbs

7

4,044

14 ft-lbs

19 ft-lbs

8

3,579

14 ft-lbs

19 ft-lbs

8

5,121

20 ft-lbs

27 ft-lbs

10

5,672

28 ft-lbs

37 ft-lbs

10

8,116

40 ft-lbs

53 ft-lbs

12

8,243

49 ft-lbs

65 ft-lbs

12

11,796

70 ft-lbs

92 ft-lbs

14

11,246

77 ft-lbs

103 ft-lbs

14

16,092

111 ft-lbs

148 ft-lbs

16

15,882

125 ft-lbs

167 ft-lbs

16

21,970

173 ft-lbs

231 ft-lbs

18

19,423

172 ft-lbs

229 ft-lbs

18

26,868

238 ft-lbs

317 ft-lbs

20

24,784

244 ft-lbs

325 ft-lbs

20

34,284

338 ft-lbs

450 ft-lbs

37° JIC Flare Torque Values

Turns Size

Ft-lbs

min.max

Assembly steps

N/A -02 6-7

N/A -03 8-9

2 -04 11-12

2 -05 14-15

1-1/2 -06 18-20

1-1/2 -08 36-39

1-1/2 -10 57-63

1-1/4 -12 79-88

1 -14 94-103

1 -16

108-113

1 -20

127-133

1 -24

158-167

1 -32

245-258

1. Make sure the tubing and threads are

clean.

2. Lubricate the threads with 10W hydraulic

oil.

3. Hand tighten the nut/sleeve to approx. 30

in-lbs.

4. Make alignment marks on the nut and

fitting.

5. Tighten to turn or torque specification.

6. When fully tightened, make a 2

nd

set of

alignment marks at the fully tighten

positioned.

NOTE: Torque values specified are for

threads lubricated with 10W hydraulic oil.

Over tightening will reduce the clamping force

resulting in loss of seal and reduction of flow.

O-Ring Boss Torque Values

Size

Ft-lbs

min.max

Assembly steps

-02 6-7

-03 8-10

-04 13-15

-05 17-21

-06 22-25

-08 40-43

-10 43-57

-12 68-75

-14 90-99

-16 112-123

-20 146-200

-24 154-215

-32 218-290

1. Verify the port, o-ring, sealing surfaces and threads

are clean and free of damage.

2. Lubricate the threads and the o-ring with 10W

hydraulic oil.

3. For an adjustable O.R.B., completely back off the lock

nut and washer.

4. Hand tighten the fitting until it contacts the port

spotface. Point the elbow or tee in the desired

direction and hold.

5. Torque to specification.

NOTE: Torque values specified are for threads lubricated

with 10W hydraulic oil.