Warning, Pinch hazard, Maintenance instructions - cradle lift – Bloomfield WFAE-55F User Manual

Page 32

363

300

007

OpM

anual for

W

F

A

E

-50

F

/FS

Electri

c

Fryer

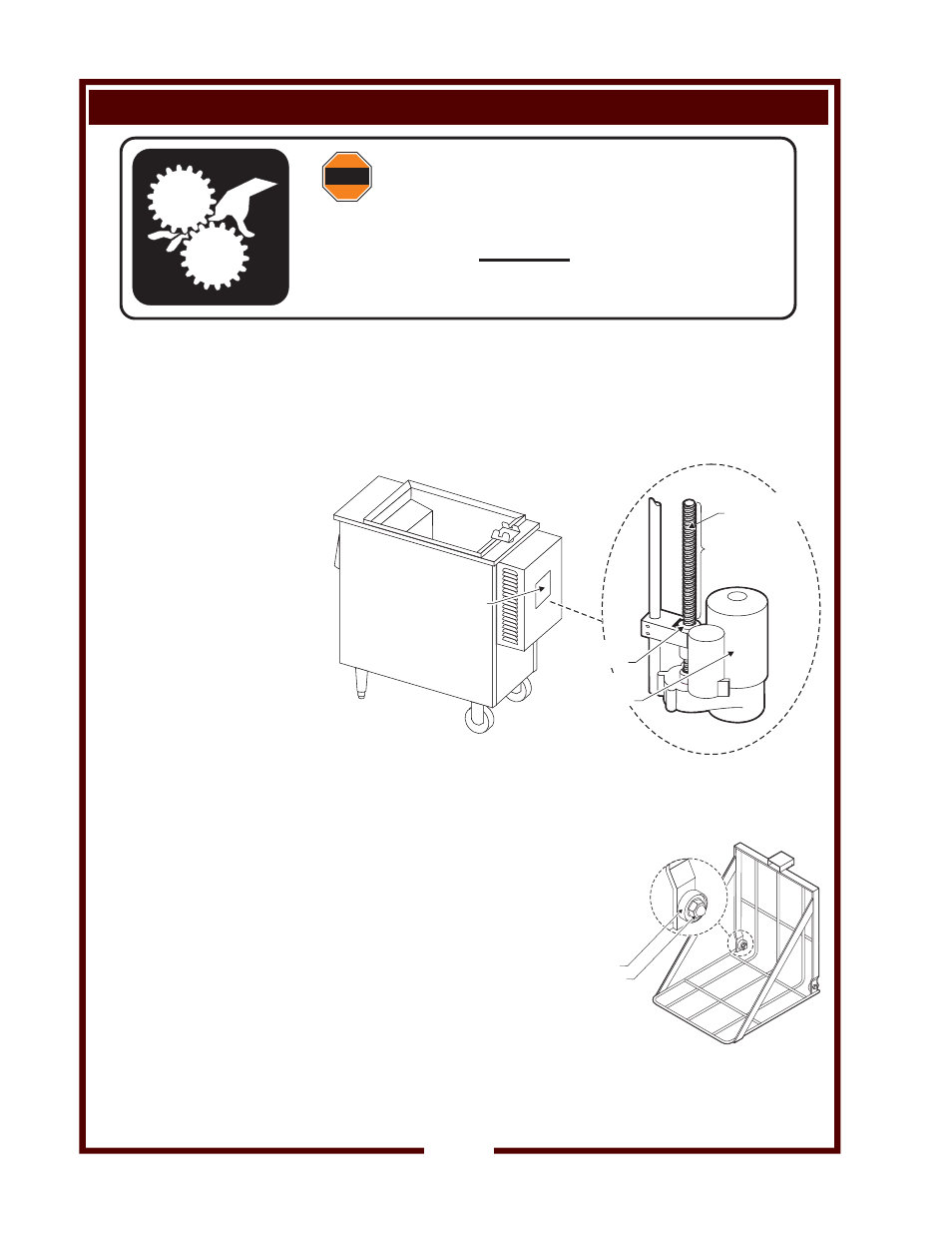

MAINTENANCE INSTRUCTIONS - CRADLE LIFT

30

NOTE:

Failure to keep the cradle lift

screw properly lubricated will

result in premature wear

of the brass lift nut Wear

caused by lack of proper

lubrication is NOT covered by

warranty.

Recommended frequency is “as

required”, and, at a minimum,

every six months. Lubricate

cradle lift screw immediately if a

grinding or rubbing noise is

heard when basket is raising.

NOTE:

Smooth operation of the rollers

is essential to the life of the

frypot. If rollers do not turn

freely during operation, they will

soon wear grooves through the

frypot wall.

IMPORTANT:

IF ROLLERS ARE FROZEN

OR OTHERWISE FOUND TO

NOT SPIN FREELY AFTER

BEING THOROUGHLY

CLEANED, REPLACE THEM

IMMEDIATELY.

Wear to the FRYPOT caused

by frozen rollers is not

covered by warranty.

WARNING

WARNING:

PINCH HAZARD

DISCONNECT FRYER FROM ELECTRIC POWER BEFORE

LUBRICATING CRADLE LIFT DRIVE SCREW

If power is not disconnected, lift motor may start unexpectedly,

causing serious injury

CRADLE LIFT LUBRICATION

Disconnect the fryer from electrical power.

Open rear access panel. Coat exposed threads of cradle lift screw

with moly (molybdenum disulfide) grease.

Close access panel and restore electrical power.

CRADLE ROLLER ASSEMBLIES

DAILY: Wash cradle in a dishwasher or in a sink with warm water and

mild soap or detergent.

Thoroughly flush roller

bearings with hot water

(under a faucet or with a

spray nozzle).

Rinse cradle thoroughly and

dry completely.

Check rollers to be sure they

roll freely.

Check the bearing nuts.

KEEP THEM TIGHT!

GREASE

THREADS

BRASS

NUT

CRADLE LIFT

DRIVE MOTOR

ACCESS PANEL

CRADLE LIFT

DRIVE SCREW

RETAINING NUT

ROLLER