Catalyst replacement, Off-season replacement recommended) – New Buck Corporation 20 Room Heater User Manual

Page 34

a. Properly functioning catalysts will be exhibiting a uniform glow from one end to the other (indicating

ignition).

b. Physically degraded catalysts will have cold places (areas not igniting) where plugging, crumbling, or

other degradation has occurred. If this occurs, the monitor probe temperature will not increase at a normal

rate. For further inspection it will be necessary to go by the disassembly method as follows:

Disassembly Inspection Method: For thorough catalysts inspection, removal of the catalyst housing is necessary

(cold heater only).

a. Spread a drop cloth in front of the heater.

b. Open door and clean out any ash.

c. Open the bypass door to give access to the two rear mounting bolts.

d. Using 9/16” wrench or 9/16” socket, loosen the four bolts and remove the catalyst housing (drop down)

and place in a suitable inspection area (it may be necessary to use penetrating oil if nuts and bolts have

seized).

e. Inspect top and bottom side of catalysts for plugging, crumbling, and other physical degradation.

1. If a problem exists, refer to the Troubleshooting section of the manual for possible cause of the

problem and solution (including replacement if necessary).

2. Reassemble if the catalysts are okay being sure the stainless steel heat reflector is positioned back in its

original position and bolt housing and heat reflector securely back in place.

CATALYST REPLACEMENT

(Off-Season Replacement Recommended)

The catalysts in your stove are designed for many years of use. If after several years of use, the efficiency of

the stove decreases or if a notable increase in the amount of smoke is observed, the catalysts may need to be

replaced. See the Catalyst Warranty prior to replacement.

1. Spread a drop cloth in front of the stove.

2. Open the door and clean out any ash.

3. Open the bypass door to give access to the two rear mounting bolts.

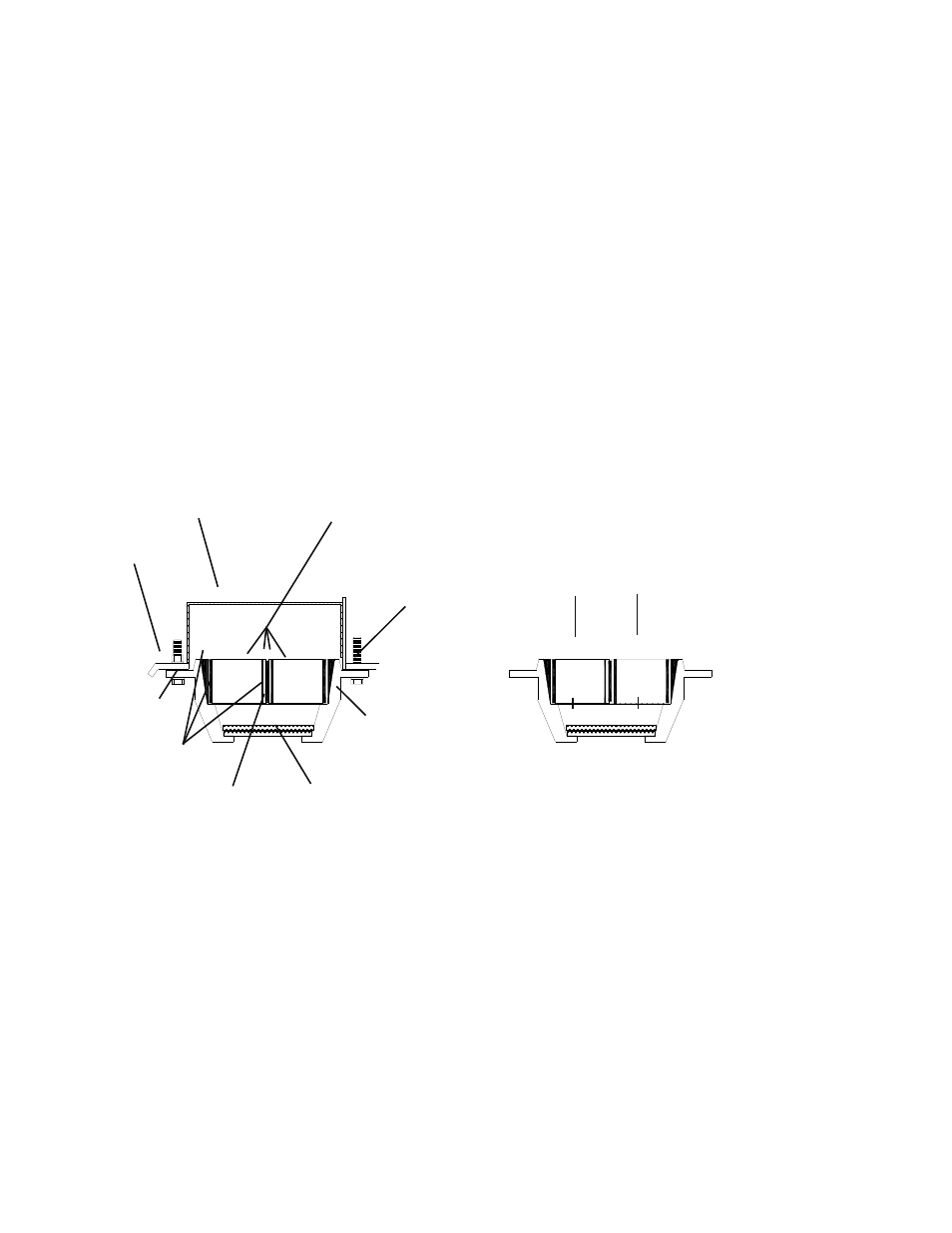

( C ) STAINLESS STEEL HEAT

REFLECTOR

( D ) CATALYST AND STAINLESS

“CAN”

( I ) UPPER

FIREBOX (INNER

TOP)

( B ) MOUNT-

ING BOLTS

( E ) INTERAM

GASKETING

( F ) STAINLESS

STEEL WIRE MESH

( G ) STAINLESS STEEL MIXING

WIRE

( A ) CATALYST

HOUSING

( H ) 1/16” X 1/2”

FIBERGLASS GASKET

VISUAL INSPECT

CATALYST