B&B Electronics DELTA Temperature Controller DTB Series User Manual

Page 5

4

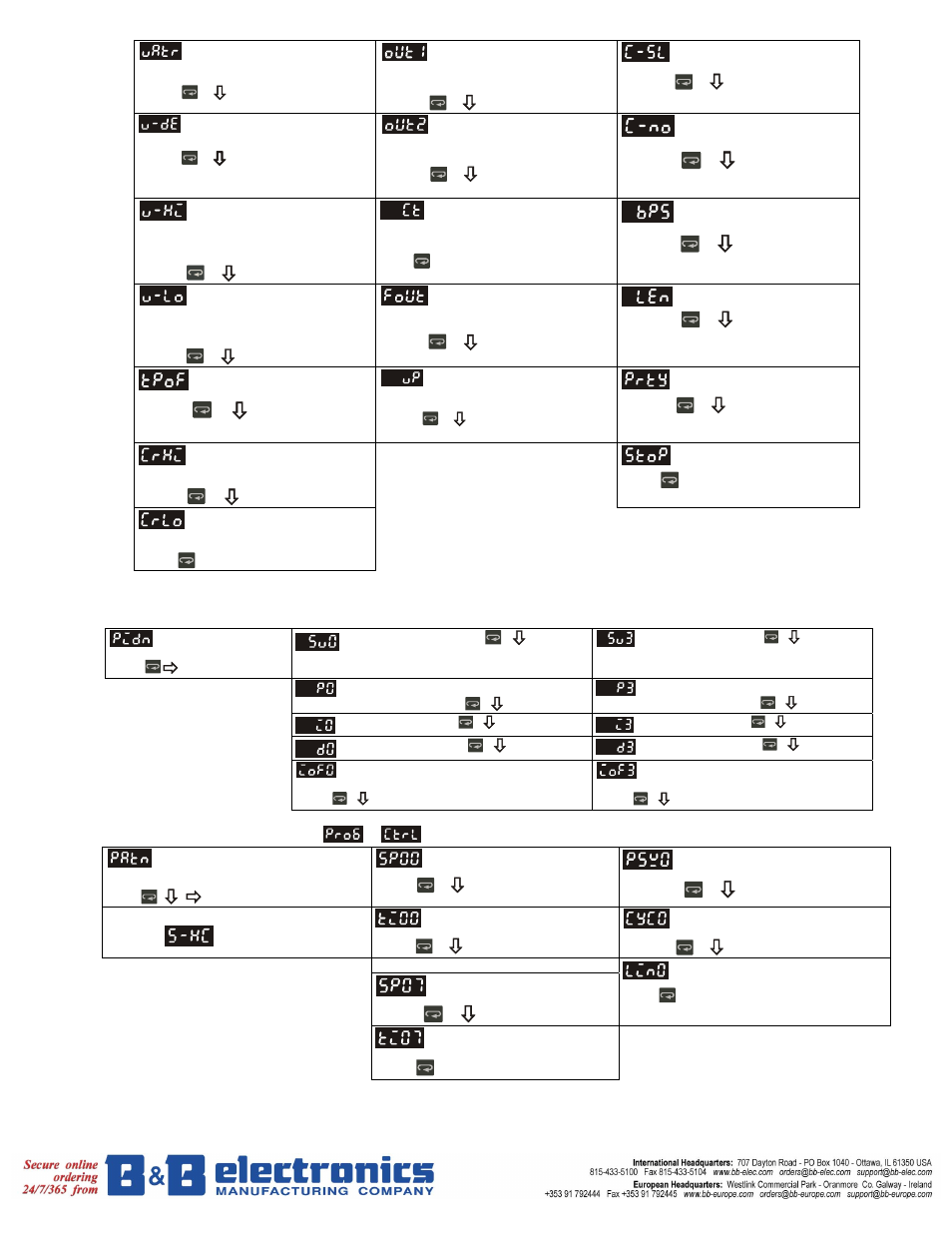

Time setting for valve from

full close to full open. (Display when

valve control is ON)

Press

Display and adjust output value

of 1st output group

(Display in PID control mode and manual

RUN mode)

Press

ASCII, RTU communication

format selection

Press

Press

Valve Dead Band setting.

Press

(Display when valve control is ON)

Display and adjust output value

of 2nd output group

(Display in dual loop PID control mode and

manual RUN mode)

Press

Communication address

setting

Press

Upper-limit regulation of

valve output with feedback to

controller. (Display when valve

signal feedback function is ON)

Press

In case of using an external CT,

the controller displays the current

value being measured by CT, if

the control output is ON

Press

to return to set target temperature

Communication baud

rate setting

Press

Lower-limit regulation of

valve output with feedback to

controller. (Display when valve

signal feedback function is ON)

Press

Valve output with feedback.

(Display when valve feedback

function is ON)

Press

Data length setting

Press

Press

Regulate temperature

deviation value

DA value feedback of valve.

(Display when valve feedback

function is ON)

Press

Back to target temperature

Parity bit setting

Press

(The setting display when analog output)

Press

Regulate upper-limit of analog

output value

Stop bit setting

Press to return input type setting

Press

Regulate lower-limit of analog

output value

(The setting display when analog output)

to return to auto-tuning mode

* 1 Scale = 2.8uA = 1.3mV for tuning output value

PID mode selection: any one of 4 groups PID modes (n=0~3) can be selected. When n=4, program will automatically select 1 group PID that is

most useful for target temperature.

Select n=0~4 to

decide PID mode.

0~3 groups PID

Press

PID setting: n=0.Press

PID setting: n=3.Press

Proportion band setting: n=0.

Press

Proportion band setting: n=3.

Press

Ti setting: n=0. Press

Ti setting: n=3. Press

Td setting: n=0.Press

Td setting: n=3.Press

Integral deviation setting: n=0.

AT setting.

Press

back to PID deviation setting

Integral deviation setting: n=3.

AT setting.

Press

back to PID deviation setting

Pattern and step editing selection: edit

in

parameter. The following display is the example operation of pattern No. 0.

select OFF

Press

Select desired editing pattern

number

select number

Edit temperature of step No. 0

of pattern No. 0

Press

Select actual step No. when

program control is executing

Press

Exit p

attern and step editing selection

Switch to and continue setting

Edit time of step No. 0 of

pattern No. 0, unit is hh.mm

Press

Set additional execution cycle

number(0 to 99)

Press

Set step No. 07 in order

Press

Edit temperature of step No. 7

of pattern No. 0

Set link pattern, OFF indicates

the program end

Press to return pattern No. editing

mode

Press to set actual step No.

Edit time of step No. 7 of

pattern No. 0, unit is hh.mm