Chassis and drive technology – Liebherr LTM 11200-9.1 User Manual

Page 18

LTM 11200-9.1

18

Chassis and drive technology

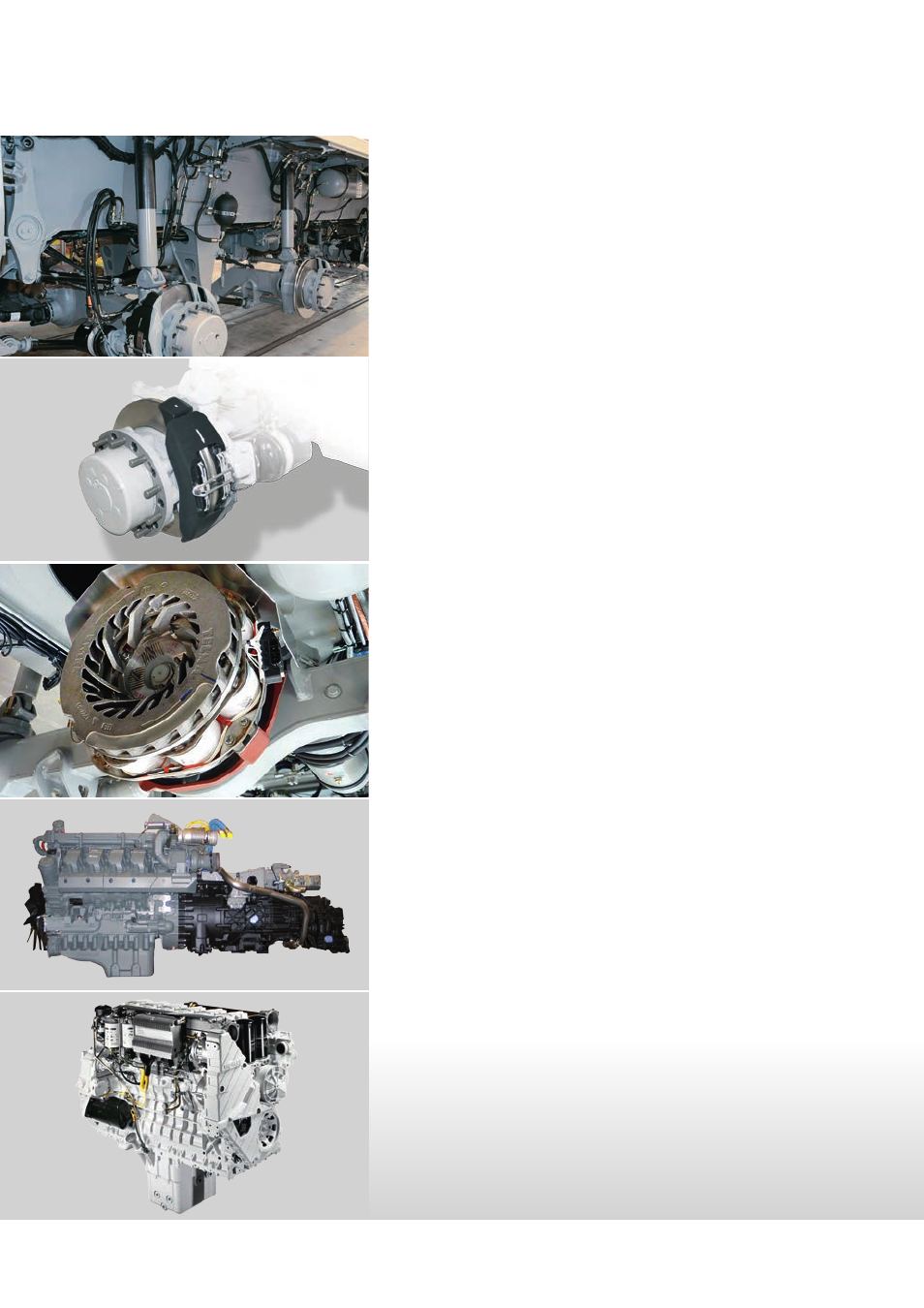

Hydro pneumatic axle suspension

„Niveaumatik“

• Maintenance-free suspension cylinders

• Large dimensions to cope with high axle loads

• Spring travel +175/-125 mm

• High side stability at cornering

• Choice of the driving conditions by fixed programmes

Air operated disk brakes

• Higher braking power, better brake control

• Improved track stability

• No brake fading at higher operation temperatures

• Higher service life

• Shorter working times for changing of the brake pads

• Brake pads with wear indication

Intarder and Telma-Eddy current

brake as standard

• No wear, low maintenance system

• Increased safety due to fast activation in milliseconds

• Reduction of operation costs

• High comfort due to braking absolutely without jolts

• Environmentally friendly brake system, no emission

and respirable dust

Chassis engine

• Powerful 8-cylinder turbo diesel engine with

500 kW/680 HP, max. torque 3,000 Nm

• Automated 12-speed-shift system ZF-TC-TRONIC with

torque converter and intarder directly at the gearbox

offers high efficiency and best comfort

• Axle 1, 2, 4 and 5 are driven axles

Superstructure engine

• 6-cylinder Liebherr turbo diesel engine,

270 kW/367 HP, max. torque 1,720 Nm

• Optimized fuel consumption due to electronic engine

management