Attachment ga20, Kinematic 2a), Dimensions – Liebherr LH 80 C Litronic User Manual

Page 11: Operating weight and ground pressure, Industrial stick 9.00 m

LH 80 C Litronic Machine for Industrial Applications

11

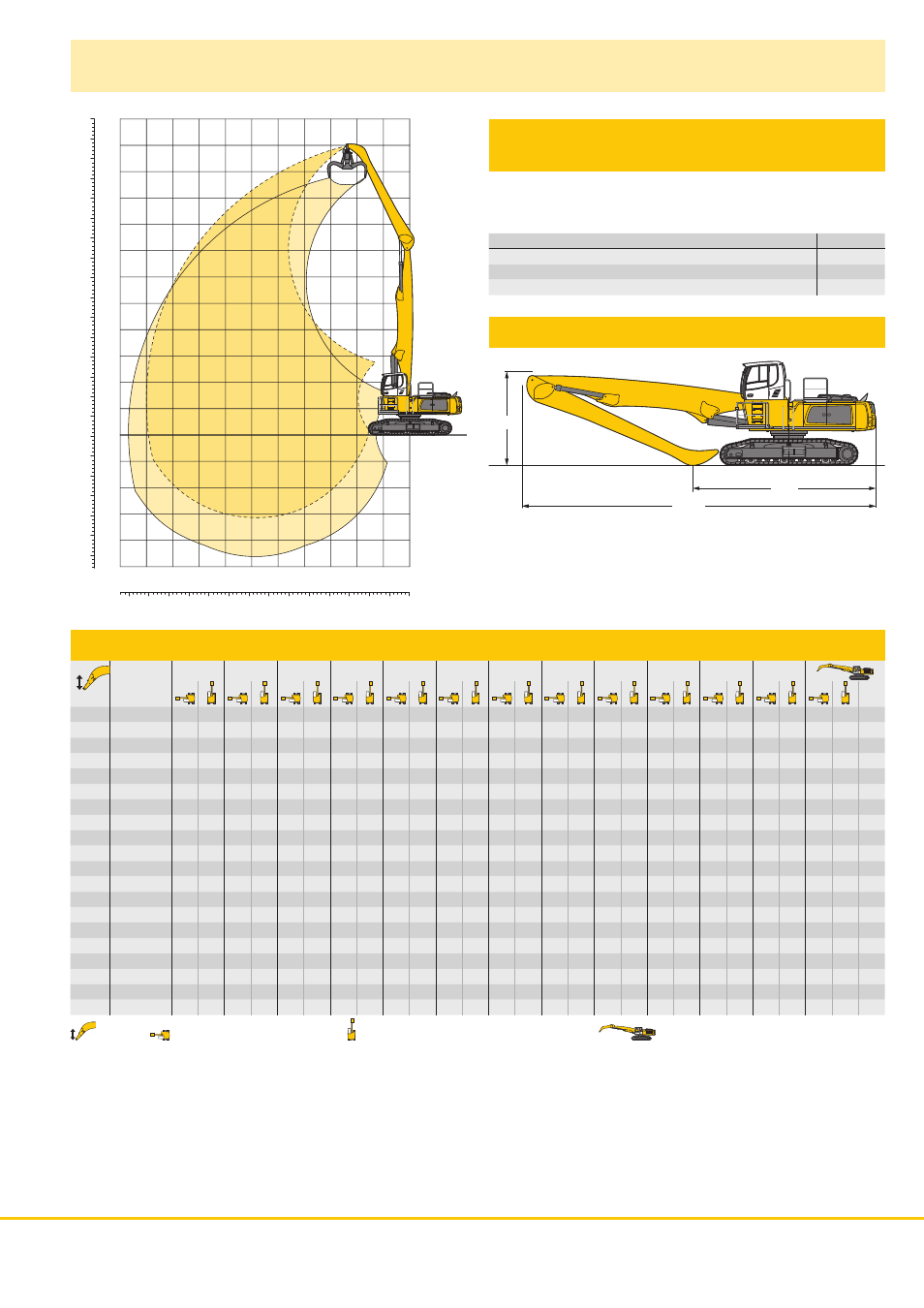

Attachment GA20

(Kinematic 2A)

H0194

16100

8350

4300

Dimensions

ft

m

ft

m

70

75

80

22

24

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

-10

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-5

-10

-15

-20

-25

-30

0

2

4

6

8

10

12

14

16

18

20

22

65

70

60 55 50 45 40 35 30 25 20 15 10 5

0

H0019

Operating Weight

and Ground Pressure

The operating weight includes basic machine with rigid cab elevation,

industrial-type straight mono boom 11.50 m, industrial-type angled

stick 9.00 m and grapple model GMM 80-5/1.70 m

3

semi-closed tines.

Undercarriage

EW

Pad width

mm 600

Weight kg 69,450

Ground pressure

on request

Industrial Stick 9.00 m

m

Under-

carriage

4.5 m

6.0 m

7.5 m

9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m

21.0 EW

11.7* 11.7*

11.2* 11.2*

7.8

19.5 EW

13.3* 13.3* 11.8* 11.8* 9.6* 9.6*

9.2* 9.2*

10.7

18.0 EW

12.9* 12.9* 11.6* 11.6* 9.7* 9.7*

8.2* 8.2*

12.8

16.5 EW

13.1* 13.1* 11.5* 11.5* 10.3* 10.3* 9.4* 9.4*

7.6* 7.6*

14.4

15.0 EW

11.4* 11.4* 10.2* 10.2* 9.3* 9.3* 7.9 8.5*

7.0 7.2*

15.7

13.5 EW

11.4* 11.4* 10.2* 10.2* 9.2* 9.2* 8.0 8.5* 6.4 7.8*

6.1 6.9*

16.8

12.0 EW

13.0* 13.0* 11.4* 11.4* 10.2* 10.2* 9.2* 9.2* 8.0 8.4* 6.5 7.8*

5.4 6.7*

17.7

10.5 EW

13.2* 13.2* 11.6* 11.6* 10.3* 10.3* 9.3* 9.3* 7.9 8.5* 6.5 7.8* 5.2 6.9

4.9 6.6

18.4

9.0 EW

13.5* 13.5* 11.8* 11.8* 10.4* 10.4* 9.4* 9.4* 7.7 8.5* 6.4 7.8* 5.2 6.9

4.5 6.1

19.0

7.5 EW

16.4* 16.4* 13.9* 13.9* 12.0* 12.0* 10.6* 10.6* 9.2 9.5* 7.5 8.6* 6.2 7.8* 5.1 6.8

4.2 5.8

19.4

6.0 EW

14.1* 14.1* 18.5* 18.5* 17.1* 17.1* 14.3* 14.3* 12.3* 12.3* 10.8 10.8* 8.7 9.6* 7.2 8.7* 6.0 7.8* 5.0 6.7 4.2 5.7

4.0 5.5

19.8

4.5 EW

30.8* 30.8* 22.6* 22.6* 17.9* 17.9* 14.8* 14.8* 12.6* 12.6* 10.1 11.0* 8.3 9.7* 6.9 8.7* 5.7 7.6 4.8 6.5 4.1 5.6

3.9 5.3

20.0

3.0 EW

4.2* 4.2* 23.7* 23.7* 18.6* 18.6* 14.9 15.2* 11.7 12.9* 9.5 11.2* 7.8 9.8* 6.5 8.7 5.5 7.4 4.7 6.4 4.0 5.5

3.8 5.2

20.0

1.5 EW

2.1* 2.1* 8.9* 8.9* 17.7 19.0* 13.7 15.5* 10.9 13.1* 8.9 11.3* 7.4 9.9* 6.2 8.4 5.3 7.2 4.5 6.2 3.9 5.4

3.7 5.2

20.0

0

EW

2.4* 2.4* 6.7* 6.7* 16.3 16.4* 12.7 15.6* 10.2 13.1* 8.4 11.3* 7.0 9.5 6.0 8.1 5.1 7.0 4.4 6.1 3.8 5.3*

3.7 4.9*

19.9

– 1.5 EW

3.3* 3.3* 6.6* 6.6* 13.0* 13.0* 11.9 15.2* 9.6 12.8* 8.0 10.9 6.7 9.2 5.7 7.9 4.9 6.8 4.3 6.0 3.8 4.5*

3.8 4.4*

19.6

– 3.0 EW

7.2* 7.2* 12.3* 12.3* 11.5 14.3* 9.3 12.2* 7.7 10.5* 6.5 9.0 5.6 7.7 4.8 6.6* 4.2 5.3*

4.0 4.5*

18.7

– 4.5 EW

12.5* 12.5* 11.3 12.8* 9.1 11.1* 7.5 9.5* 6.4 8.2* 5.5 6.9* 4.8 5.6*

4.5 5.0*

17.1

– 6.0 EW

9.0 9.3* 7.4 8.1* 6.3 6.8*

6.0 6.4*

14.1

– 7.5 EW

Height

Can be slewed through 360° In longitudinal position of undercarriage

Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and can be slewed through 360° on a firm, level supporting surface.

Capacities are valid for 600 mm wide triple grouser pads (resp. flat pads). Indicated loads comply with the ISO 10567 standard and do not exceed

75 % of tipping or 87 % of hydraulic capacity. The lift capacity values indicated are attained at the corresponding operating temperature. This operating

temperature is ensured by continuous movement of the boom. Weights of fitted working tools (grabs, load hooks, etc.) and load accommodation

equipment are to be deducted from the lift capacity values. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic

elements, or the maximum permissible lifting capacity of the load hook.

In accordance with the harmonised European Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe

fracture safety valves, an overload warning device, a load hook and a lift capacity chart.