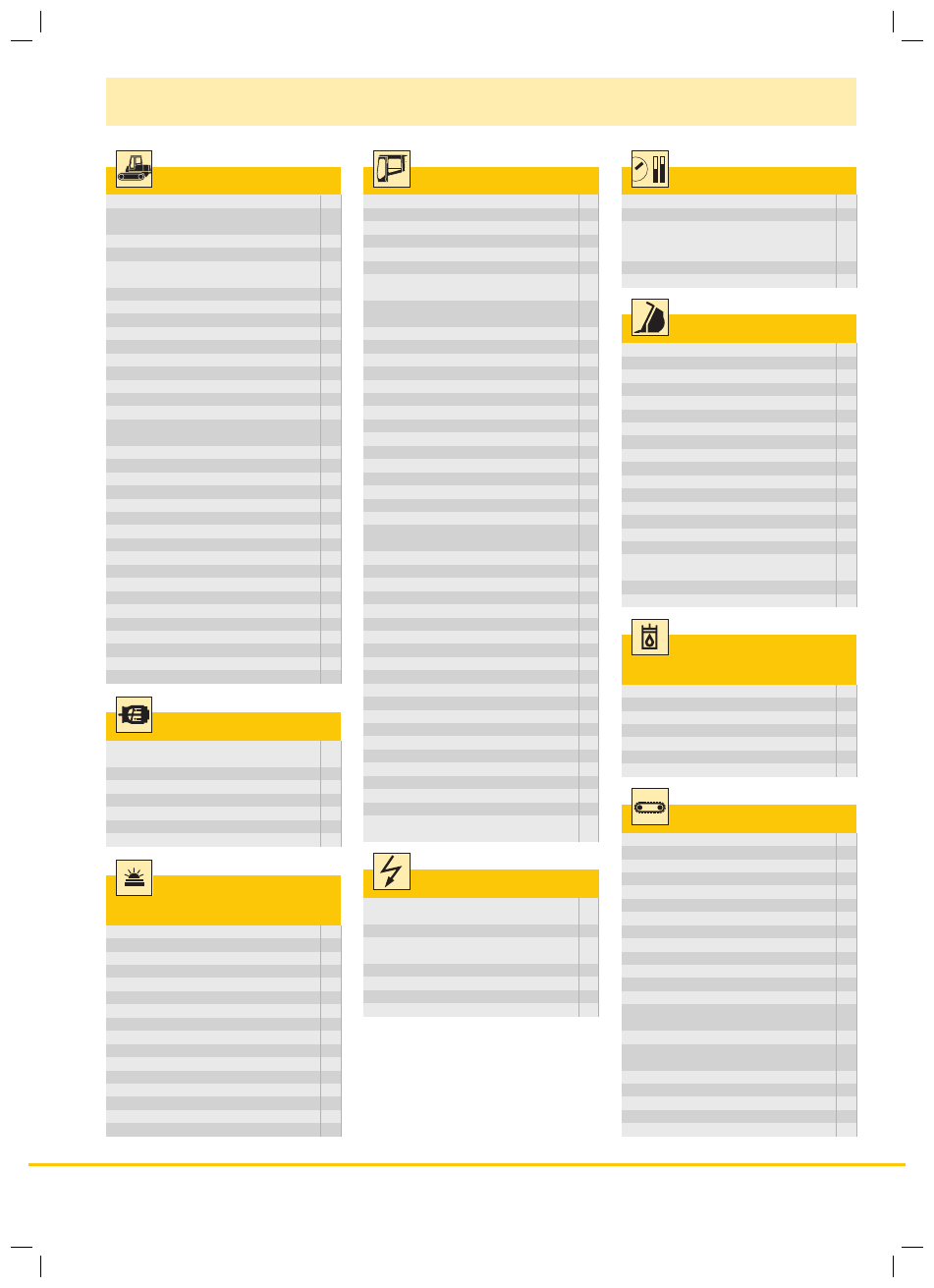

Equipment, Basic machine, Travel drive – Liebherr LR 634 Litronic User Manual

Page 19: Track frame, Electrical system, Operator’s cab, Displays, Control and warning lights, Attachments, Hydraulic equipment

LR 624 Litronic LR 634 Litronic

19

Equipment

• = Standard, + = Option

(1) only for LR 634, (2) only for LR 624

Basic machine

Towing system (air pressure cartridge)

•

Intake air pre-cleaner with automatic

dust ejector

(1) •

Liebherr Diesel engine D934

•

Cab tilting system

•

Combination cooler, wide-meshed (for

water, hydraulic oil, fuel, and charge air)

•

Radiator protection grille, hinged

•

LH-ECU electronic engine management

•

Hydrostatic fan, thermostatic. controlled

•

Fan guard

•

Engine access doors, hinged, lockable

•

Lifting lugs

•

UPS high injection pressure fuel system

•

Dry type air filter (quick change)

•

Fuel priming pump

•

Fuel water separator

•

Vandalism protection (fuel tank cap

and service doors lockable)

•

Tool kit (with towing kit)

•

Towing hitch, rear

•

Towing hitch, front

•

Tank guard

+

Diesel particles filter

+

Exhaust manifold isolated

+

Radiator guard Heavy Duty, pivoting

+

Bio degradable Liebherr hydraulic oil

+

Air pre-cleaner engine

+

Landfill equipment

+

Reversible fan

+

Back up alarm

+

Filler guard

+

Special paint

+

Steel mill equipment

+

Fuel water separator, electric heater

+

Tunnel equipment

+

Central lubrication system

+

Travel drive

Duo cone seals with electronic

seal-integrity control

•

Electronic control

•

Parking brake, automatic applied

•

Liebherr hydrostatic travel drive

•

Litronic control system

•

Spur gear and planetary gear

•

Final drive protection ring

+

Track frame

Track shoes, double grouser, 20”

•

Master link, two-piece

•

Lubricated chains

•

Track guides, front and rear

•

Track chains grease tensioner

•

Track rollers, lifetime lubricated, x6

•

Track idler guards

•

Track idlers, lifetime lubricated

•

Equalizer bar, cushion mounted

•

Carrier rollers, lifetime lubricated, x1

•

Sprocket guards

•

Sprocket segments, bolted, x5

•

Rear striker bar

+

Track shoes, double grouser, 20” with

trapezoidal center holes

+

Track shoes, double grouser, 22”

+

Track shoes, double grouser, 22” with

trapezoidal center holes

+

Track shoes, double grouser, 24”

(1) +

Track guards

+

Center track guides

+

Version LGP

+

Sprocket segments with recesses

+

Electrical system

Starter motor

LR 624 5.4 kW, LR 634 7.8 kW

•

Battery main switch

•

Batteries maintenance free, x2

LR 624 135 Ah, LR 634 170 Ah

•

Alternator 80 A Heavy Duty

•

Power port 24 V (electric compartment)

•

Rotating beacon

+

Anti-theft system, electronic

+

Operator’s cab

Storage space under armrest, lockable

•

Towing switch

•

Armrests, adjustable

•

Speed switch, work/travel modes

•

Pressurization with air recirculation

•

Louvered vents, adjustable, x12

•

Single joystick implement control with

integrated magnetic detent functions

•

Single joystick travel control (travel speed,

all direction and steering motions)

•

Mechanical suspension seat

•

Fresh air intake and recirculation air filter

•

Beverage holder

•

Working lights (halogen), rear, x2

•

Working lights (halogen), front, x4

•

Horn

•

Dome light

•

Coat hook

•

Air conditioner

•

Engine rpm switch, infinitely variable

•

Emergency stop

•

Radio installation provision

•

ROPS/FOPS structures

•

Rearview mirror inside

•

Windshield washer system

•

Windshield wipers front and rear,

with intermittent function

•

Sliding side window left

•

Sliding side window right

•

Key start switch

•

Seat belt, automatic retractable

•

Park lock lever

•

Safety glass, tinted

•

Pull-down sunshade

•

Power port 12 V (storage space)

•

Heater and defroster

•

Braking pedal for single-lever control

+

Air suspension seat

+

Fire extinguisher

+

Additional working lights, rear, x2

+

Condenser unit pivoted

+

Cooler box for storage space (12V)

+

Radio

+

Seatback extension

+

Reversing camera system

+

Rearview mirrors, outside, left and right

+

Protective grid for window

+

V-pattern travel control (travel speed,

direction motions) with steering pedals

+

Displays

Hour meter

•

Engine coolant temperature

•

Digital LC-display with scroll key

(Diesel engine rpm, travel speeds,

service codes and towing mode)

•

Fuel level

•

Hydraulic oil temperature

+

Control and

warning lights

Air inlet heater Diesel engine

•

Diesel engine malfunction

•

Electronic travel control system

•

Parking brake

•

Preselection automatic lift kickout

•

Hydraulic oil temperature

•

Battery charging control

•

Fan control

•

Oil level duo cone seals, left and right

•

Pump replenishing pressure

•

Preselection automatic bucket positioner

•

Preselection float position

•

Maintenance oil return filter

•

Maintenance fuel water separator

•

Maintenance air filter

•

Main warning light

•

Attachments

Rear bumper

•

Lower bucket pins, lifetime lubricated

•

Z-bar linkage

•

Rear drawbar hitch, rigid

+

Bolt-on adapters

+

Weld-on adapters, flush mounted

+

Trash guard multi-purpose bucket

+

Trash guard for standard bucket

+

Winch

+

HD-bucket

+

3-shank ripper, radial

+

Multi-purpose bucket

+

Waste handling bucket

+

Standard bucket with back drag edge

+

Lifting cylinder guards

+

Tilt cylinder guards

+

Clamping cylinder guards,

multi-purpose bucket

+

Bolt-on cutting edges, reversible

+

Bolt-on cutting segments, reversible

+

Hydraulic

equipment

Load Sensing System

•

Automatic lift kickout

•

Automatic bucket positioner

•

Bucket quick drop

•

Bucket float position

•

Hydraulic control multi-purpose bucket

+

Hydraulic control 3-shank ripper

+

Options and/or special attachments, supplied

by vendors other than Liebherr, are only to

be installed with knowledge and approval of

Liebherr to retain warranty.

Subject to changes.

NTB_LR624-634_T_enGB_01.indd 19

01.06.11 12:22