Basic machine, Engine, Travel drive, control – Liebherr LR 634 Litronic User Manual

Page 14: Track frame, Operator’s cab, Noise emission, Hydraulic equipment

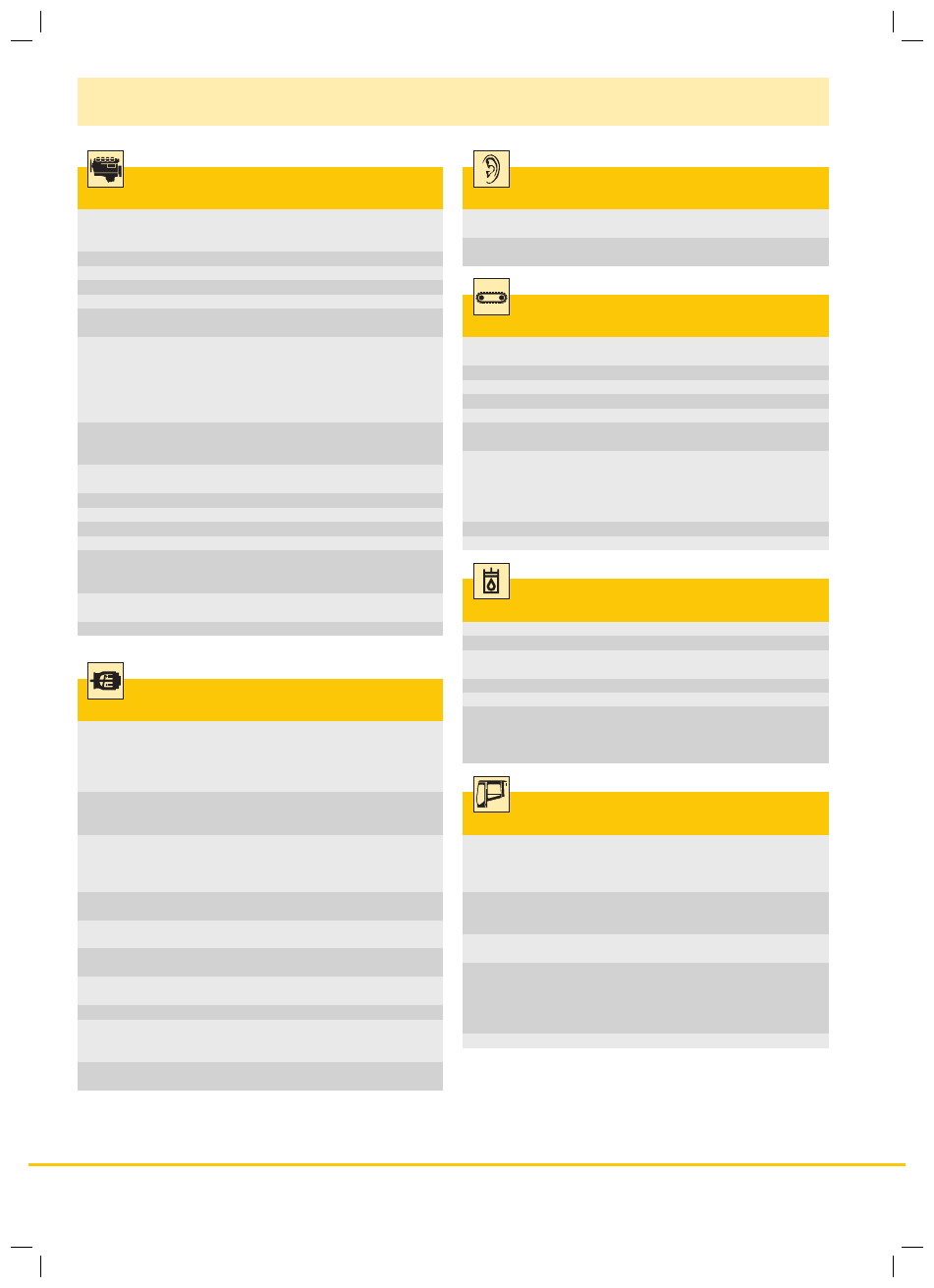

Basic machine

Engine

LR 624

LR 634

Liebherr Diesel engine

D934 S A6

D934 L A6

emission regulations according to 97/68/EC,

2004/26/EC Stage IIIA and EPA/CARB Tier 3

Net power (ISO 9249)

105 kW / 143 HP

129 kW / 175 HP

Net power (SAE J1349) 105 kW / 141 HP

129 kW / 173 HP

Engine rating

1,800 rpm

1,800 rpm

Displacement

6.4 l / 391 in

3

7.0 l / 427 in

3

Bore/stroke

122 mm / 136 mm

122 mm / 150 mm

(4.80 in / 5.35 in)

(4.80 in / 5.91 in)

Design

low emission 4 cylinders in-line Diesel engine

with intern exhaust gas recirculation AGR,

turbo-charger, air-to-air aftercooler, single cylin-

der head, wet cylinder sleeves, 4 valves per

cylinder, gear driven water pump as well as fuel

pump and oil pump

Fuel system

Unit-Pump-System (UPS) direct high injection

pressure fuel system, electronic engine manage-

ment LH-ECU (Liebherr-Electronic Control Unit)

Lubrication

pressurised lube system, engine lubrication

guaranteed for inclination up to 45-degree

Operating voltage

24 V

24 V

Alternator

80 A, Heavy-Duty

80 A, Heavy-Duty

Starter

5.4 kW

7.8 kW

Battery

2 x 135 Ah / 12 V

2 x 170 Ah / 12 V

Air cleaner

dry-type air cleaner with pre-cleaner and

automatic dust ejector*, main and safety

elements with radial seal

Cooling system

combination cooler with single cooling units for

water, hydraulic oil, fuel and intake charge air

Cooling fan

hydrostatically driven, thermostatically controlled

* only for LR 634

14

LR 624 Litronic LR 634 Litronic

Travel drive, control

LR 624

LR 634

Drive system

closed-loop infinitely variable hydrostatic travel

drive powered by two axial piston variable dis-

placement pumps and two axial piston variable

displacement motors in swash-plate design,

each track is driven indepedently from each other

Travel speed

infinitely variable electronic-controlled

Speed range 1: 0–6.5 km/h / 0–4.0 mph (work)

Speed range 2: 0–10.0 km/h / 0–6.2 mph (travel)

Litronic-System

electronic engine speed sensing control

(load-sensing feature) automatically adjusts

travel speed and drawbar pull to match

changing load conditions

Steering

hydrostatic, unlimited maneuvrability for full

power turns and counterrotation

Service brake

hydrostatic, dynamic braking effect from travel

drive system

Parking/

multi-disc brake, wear-free, automatically

emergency brake

applied with neutral joystick position

Cooling system

hydraulic oil single unit built in combination

cooler

Filter system

micro cartridge filters in cooling circuit

Final drive

combination spur gear with planetary gear,

double sealed (duo cone seals) with electronic

seal-integrity indicator

Control

single-lever travel control for all travel and

steering motions, as well as for counterrotation

Track frame

LR 624

LR 634

Chains

sealed and lubricated, track chain tension via

grease tensioner and hydraulic cylinder

Chain links

39 each side

38 each side

Sprocket segments

5 each side

5 each side

Track rollers

6 each side

6 each side

Carrier roller

1 each side

1 each side

Track shoes standard

508 mm / 20”,

508 mm / 20”,

double grouser

double grouser

Track shoes optional

560 mm / 22”,

560 mm / 22”,

double grouser

double grouser

610 mm/ 24”,

double grouser

Wider track shoes available on demand

Grouser height

35 mm / 1.38 in

42.5 mm / 1.67 in

Mount

pivot shafts and equalizer bar (cushion mounted)

Operator’s cab

LR 624

LR 634

Heater and air

pressurised, with fresh air intake and recircula-

conditioner

tion air filter, 12 louvered vents for all tem-

perature controlled cab’s areas, sliding side

windows left and right

ROPS/FOPS cab

integral Rollover Protective Structure according

to EN ISO 3471 and Falling Objects

Protective Structure according to EN ISO 3449

Operator’s seat

adjustable, suspended seat adjustable to

operator’s weight

Monitoring System

combination of analog and digital instrument

panel: LC-Display with scroll key for engine

rpm, travel speed and service codes; automatic

monitoring from operating pressures, tempera-

tures and fill levels; hour meter gauge

Tilting system

tiltable 40° to the rear with hydraulic hand pump

Noise emission

LR 624

LR 634

Operator sound exposure L

pA

= 78 dB(A)

L

pA

= 78 dB(A)

(ISO 6396)

(emission at the operator’s position)

Exterior sound pressure L

wA

= 109 dB(A)

L

wA

= 110 dB(A)

(2000/14/EC)

(emission in the environment)

Hydraulic equipment

LR 624

LR 634

Hydraulic system

Load-sensing proportional pump flow control

Pump type

variable displacement pump (swash-plate design)

Pump flow max.

162 l/min /

209 l/min /

35.6 Imp. gpm

46.0 Imp. gpm

Pressure limitation

260 bar/ 3,770 PSI

260 bar/ 3,770 PSI

Filter system

return filter with magnetic rod in hydraulic tank

Control

single joystick implement control for all bucket

functions, with magnetic detent functions for

float position as well as for automatic bucket

positioner and for automatic lift kickout

NTB_LR624-634_T_enGB_01.indd 14

01.06.11 12:21