Reliability, Liebherr powertrain, Robust steel construction – Liebherr PR 754 Litronic User Manual

Page 9: Secrets of long-term reliability

9

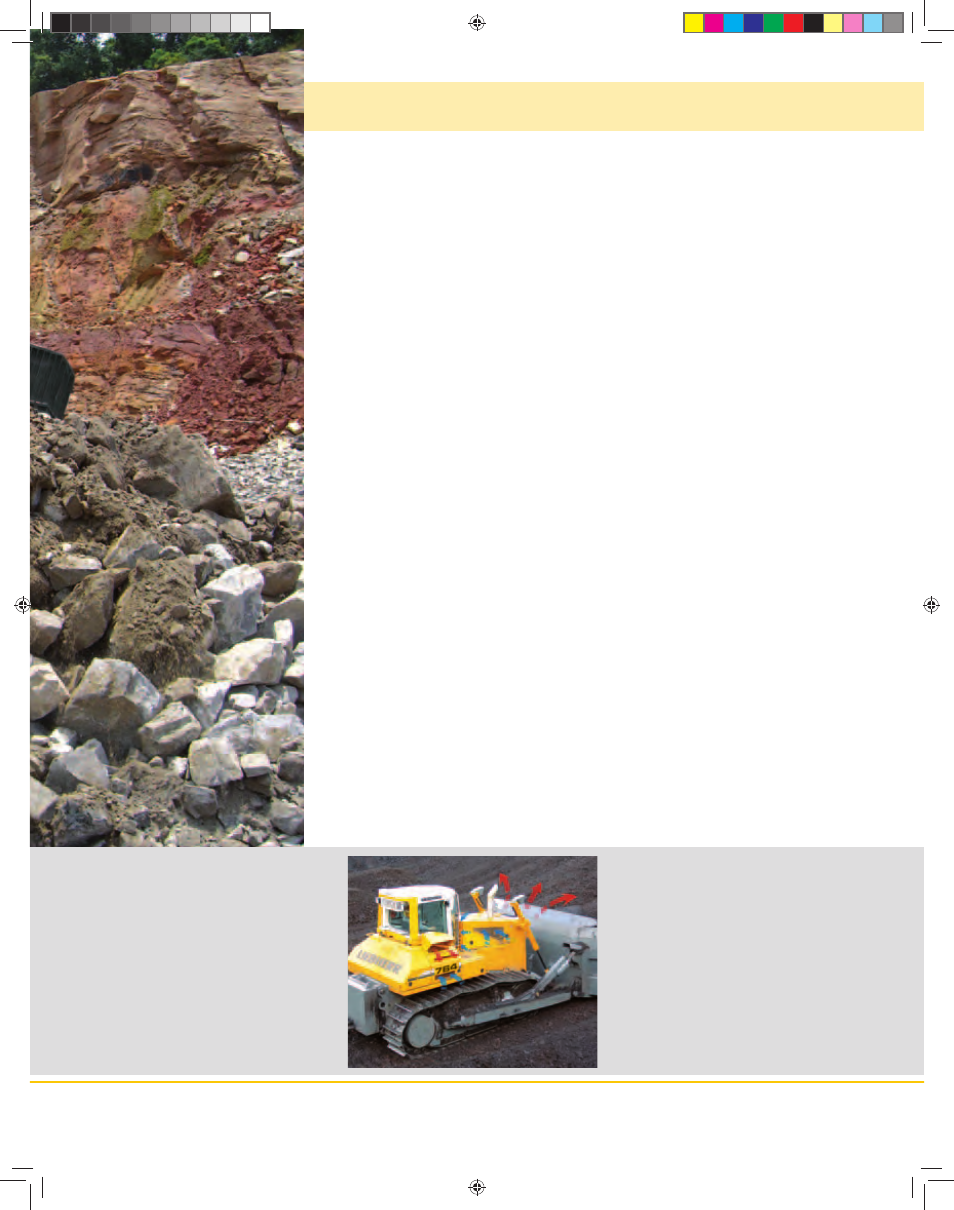

PR 754 Litronic PR 764 Litronic

Reliability

Well-proven technologies and high quality are what keeps a machine ready for use.

Liebherr develops and builds its own components and assemblies specifically for

use on construction and civil engineering machinery, so that their strength can be

guaranteed however difficult the application.

Liebherr powertrain

Liebherr engines

Liebherr diesel engines have been developed for the

toughest imaginable operating conditions. A rigid lad-

der-type frame reduces engine vibration and provides

the strength needed for maximum operating reliability

and long service life.

Wear-free driveline

concept

A tried and tested system: Liebherr’s hydrostatic travel

drive needs no torque converter, manual-shift gearbox,

differential steering or steering clutches. The system’s

hydraulic pumps and motors are standardized, effec-

tively wear-free in operation and exceptionally reliable.

Long-life final drives

Of ample dimensions, Generation 4 final drives are

designed to withstand the most severe loads. Double

transmission seals with automatic leak detection en-

hance reliability even more.

Robust steel construction

Box-section main frame

The main frame is of box-section design – a well-

proven principle for maximum torsional stiffness and

optimal absorption of forces. Cast steel is used for

components subject to high stress.

Rear-mounted ripper

Liebherr rippers are built for heavy-duty tasks, and

have extra protection at all areas exposed to wear.

Secrets of long-term reliability

Modern cooling system

Two hydrostatically driven fans and a wide-meshed ra-

diator guarantee optimal cooling performance, even in

dusty environments.

Protected electrics

High quality cable protection prevents mechanical

damage to the cable harness.

Modern cooling system

• Two electronically controlled fans draw in the volume

of air actually needed to keep the hydraulic fluid and

engine oil temperatures stable as loads vary. All com-

ponents operate in their most favorable temperature

ranges, thus avoiding unnecessary strain and pro-

longing their trouble-free operating life.

• Cooling air is drawn in from clean zones around

the machine, to keep dust contamination to a

minimum.

• Optional: a reversible fan for automatic radiator

cleaning when operating in extremely dirty or

dusty conditions.

Component endurance tests

• Even at the design stage, components

are subjected to FE analysis in order to

determine their dimensions in relation to

the loads they will encounter.

• All components undergo long-term labo-

ratory and field testing, and only those

that comply with Liebherr’s high quality

standards are approved for production.

PR754_764_BT_enUS.indd 9

01.02.11 10:12