Basic machine, Engine, Travel drive, control – Liebherr PR 754 Litronic User Manual

Page 12: Operator’s cab, Undercarriage, Noise emissions

12

PR 754 Litronic PR 764 Litronic

Basic machine

Engine

PR 754

PR 764

Liebherr diesel engine

D 946 L A6

D 9508 A7

Emission regulations according to 97/68/EC,

2004/26/EC Stage IIIA and EPA/CARB Tier 3

Rating (SAE J1349)

250 kW / 335 HP

310 kW / 416 HP

Rating (ISO 9249)

250 kW / 340 HP

310 kW / 422 HP

Rated speed

1,600

1

/min

1,600

1

/min

Displacement

12 l / 733 in

3

16.2 l / 989 in

3

Design

6 cylinder in-line-engine

8 cylinder V-engine

(wet-sleeve) water-cooled, turbocharged,

intercooled

Injection system

Direct fuel injection,

Direct fuel injection,

pump-line-nozzle

Common Rail

system, electronic

system, electronic

control

control

Lubrication

Force-feed lubrication, engine lubrication

guaranteed for inclinations up to 45° (PR 754)

and 40° (PR 764)

Operating voltage

24 V

24 V

Alternator

80 A

80 A

Starter

7.8 kW / 11 HP

7.8 kW / 11 HP

Batteries

2 x 225 Ah / 12 V

2 x 225 Ah / 12 V

Air cleaner

Dry-type air cleaner with safety element,

aspirated pre-cleaner, service gauge in cab

Cooling system

Combi radiator, comprising a radiator for water

and charge air. Hydrostatic fan drive

Travel drive, control

PR 754

PR 764

Transmission system

Infinitely variable hydrostatic travel drive,

independent drive for each track

Travel speed*

continuously variable

Speed range 1 (reverse) 0– 4.0 km/h / 2.5 mph (4.8 km/h / 2.9 mph)

Speed range 2 (reverse) 0– 6.5 km/h / 4.0 mph (7.8 km/h / 4.8 mph)

Speed range 3 (reverse) 0–11.0 km/h / 6.8 mph (11.0 km/h / 6.8 mph)

* Pre-adjusted, all speed ranges can be custo-

mized on the travel joystick (memory function)

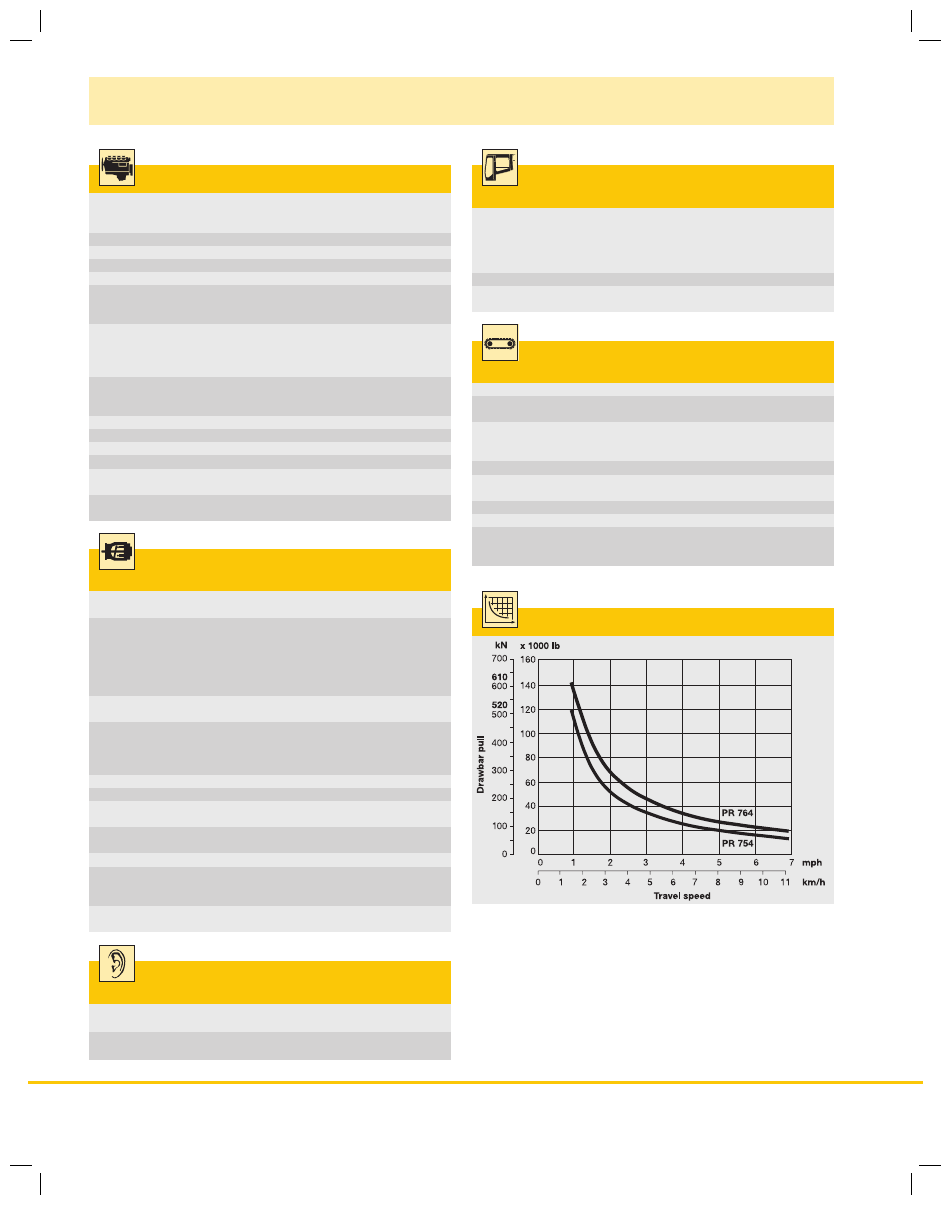

Drawbar pull at

520 kN

610 kN

1.5 km/h / 0.9 mph

116,901 lbf

137,134 lbf

Electronic control

Electronic engine speed sensing control (load

sensing feature) automatically adjusts travel

speed and drawbar pull to match changing

load conditions

Steering

Hydrostatic

Service brake

Wear-free, hydrostatic (dynamic braking)

Automatic park brake

Wear-free, wet multiple-disc brakes, automa-

tically applied with neutral joystick position

Cooling system

Separate hydraulic oil cooler, hydrostatically

driven and thermostatically controlled

Filter system

Micro cartridge filters in cooling circuit

Final drive

Heavy-duty combination spur gear with plane-

tary final gear, double sealed with electronic

seal-integrity indicator

Control

Single joystick for all travel and steering

motions, as well as for counter rotation

Operator’s cab

PR 754

PR 764

Cab

Resiliently mounted cab with positive pressure

ventilation, can be tilted with hand pump 40°

to the rear. With integrated ROPS Rollover Pro-

tective Structure (EN ISO 3471) and FOPS Fal-

ling Objects Protective Structure (EN ISO 3449)

Operator’s seat

Comfort seat, adjustable to operator’s weight

Monitoring

Combined analog / LC display, automatic

monitoring of abnormal operating conditions

Undercarriage

PR 754

PR 764

Design

Undercarriage with rigid or bogie suspension

Mount

Via separate pivot shafts and an oscillating

equalizer bar

Chains

Lubricated single-bar grouser shoes SESS*,

track chain tensioning via steel spring and

grease tensioner

Links, each side

44

44

Track rollers/carrier

rollers

7/2 each side

7/2 each side

Sprocket segments

5 each side

3 each side

Track shoes standard

560 mm / 22” SESS

610 mm / 24” SESS

Track shoes optional

610 mm / 24” SESS

660 mm / 26” SESS

660 mm / 26” SESS

710 mm / 28” SESS

710 mm / 28” SESS

760 mm / 30” SESS

Noise emissions

PR 754

PR 764

Operator sound exposure L

pA

= 78 dB(A)

L

pA

= 79 dB(A)

ISO 6396

emission at the operator’s position

Exterior sound pressure L

wA

= 113 dB(A)

L

wA

= 114 dB(A)

2000/14/EC

emission in the environment

Drawbar pull PR 754/PR 764

Usable drawbar pull will depend on traction and weight of tractor

* SESS Super Extreme Service Shoes

NTB_PR754-764_T_enUS_11-02.indd 12

27.01.11 11:41