Liccon-assisted telescoping system – Liebherr LTM 1250-6.1 User Manual

Page 8

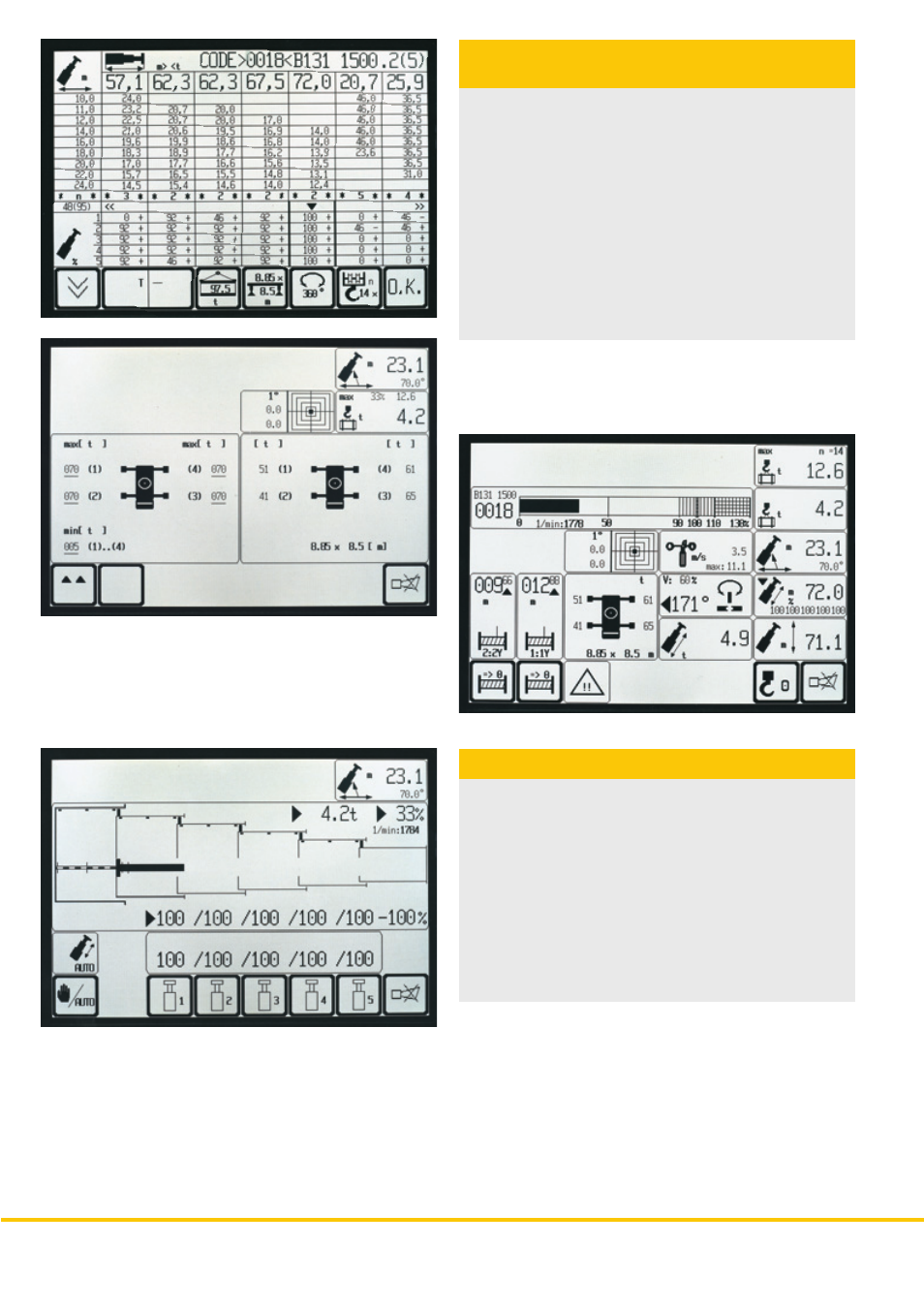

• Standard application programs: Safe load indicator (LMB),

configuration program with configuration image, telescoping

program with telescoping image, supporting force display,

control parameter program, test system; and as an option,

the work area limitation and the LICCON work planner

• Setting of the crane configuration by convenient

interactive functions

• Safe and reliable acknowledement of the crane

configuration set

• Representation of all essential data by graphic symbols on

the operating image

• With integrated wind speed control

• Reliable cut-off device in the event of exceeding the

admissible load moments

• Safe working load values for any intermediate boom length

• Winch indications for ultra-precise lifting/lowering of the load

LICCON computer system for control

and monitoring functions

Legend:

LSB - Liebherr system bus 1

LSB - Liebherr system bus 2

LSB - Liebherr system bus 3

LSB - Liebherr system bus 4

CAN - Bus

SCI - serial communication interface

1 Input/output module for control of the suspension, Liebherr

Diesel engine, automatic transmission, control functions,

pneumatic control of brake functions

1a Instruments keyboard unit in driver’s cab

2 Input/output module for differential locks, display functions

2a Instruments keyboard unit in driver’s cab

3 Input/output module for outrigger system - right

3a Control unit for outrigger system - right

4 Input/output module for outrigger system - left

4a Control unit for outriggers system - left

5 Input/output module for engine brake, cruise controller, speed

setter, control of Diesel engine (steering column switch right)

and automatic transmission

6 Control of automatic transmission

• Telescoping by single-stage hydraulic ram with hydraulic

driving tenons (patented internal interlocking system)

• Telescoping procedure controllable by convenient operator’s

guide on the monitor, precise approach of the interlocking

positions

• Telescopable loads are displayed on the

LICCON operating image

• Rapid-cycle telescoping system with “automatic mode”, i.e.

all automatic telescoping of the boom to the desired length

• Particularly compact and light-weight telescopic system,

thus increased lifting capacities specially with long booms

at large radii

• Automatic cushioning in end positions during telescoping

and retracting for the preservation of the structural members

LICCON-assisted telescoping system

7 Control of injection pump – Liebherr Diesel engine/carrier

8 Slewing sensor in slipring unit

9 Connection of Liebherr system bus (LSB 1, 2, 3, 4)

10 LICCON central unit

11 LICCON monitor in crane cab

12 Length sensor and cable drum/energy cable for interlocking

gripper/telescopic boom

13 Inductive sensors (12 x)

14 Angle sensor on base section

15 Cable drum for items 16, 17, 18 and for luffing jib

16 Wind sensor

17 Hoist limit switch

18 Angle sensor

19 Input/output module for electronic control of Diesel

engine/superstructure, air flap, ventilator clutch, exhaust

flap

20 Control injection pump – Liebherr Diesel

engine/superstructure

21 Control lever

22 Pressure sensor (4 x) for output management and LMB

(safe load indicator)

LSB 2

CAN-Bus

9

20

4

4a

21

21

12

14

19

11

10

13

7

10

LTM 1250-6.1

LTM 1250-6.1