Variable drive and steering concept – Liebherr LTM 1250-6.1 User Manual

Page 11

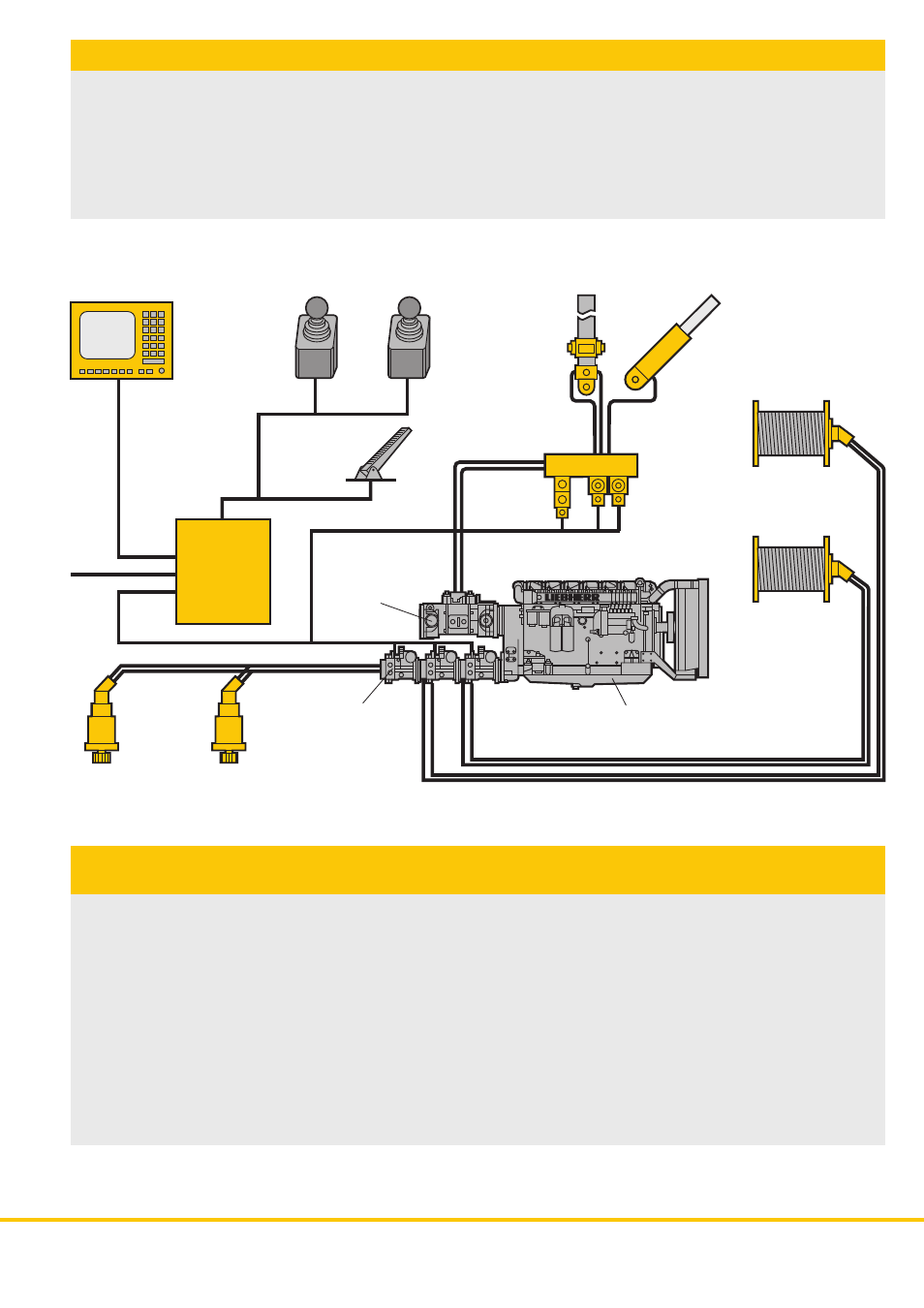

Electric/electronic crane control with integrated safe load indicator

• Control of winches, slewing gear as well as luffing and

telescoping motions by the LICCON system (PLC control)

• Four working motions can be performed independent from

one another

• Speeds of hoisting/lowering, slewing and luffing are prese-

lectable in 5 steps

• Luffing speed controlled automatically dependent on the

boom length

• Extremely short response times when initiating crane motions

• Hoist gear and slewing gear are operating in a “closed oil

circuit”. This ensures high-precision lifting, lowering and

slewing of loads. Moreover, the potential energy generated

during lowering is not transformed into heat but can be

reemployed for a 2nd motion which results in the particular

advantage of fuel saving and reduced thermal exposure of

the oil than in an open circuit

• Functional test of all essential components by the LICCON

test system

On the carrier

• Eddy-current-brake

• Stow-away box for sling gear and stand timber

• Air-conditioning system

• Trailer coupling D12/D19

• Radio preparation

• Seat heating for driver’s and co-driver’s seat

• Fog lamps

• CD radio set

On crane superstructure/telescopic boom

• 2nd hoist gear

• Air-conditioning system

• Seat heating

• Work area limitation

• Work projector 1 x 70 W on cabin roof

• Two work projectors (Xenon) – electrically adjustable – on

boom base section

• whip line

• Erection jib

• GSM module for remote diagnostics

• Radio preparation

• CD radio set

• Crane data logger

Further optional features by request.

Optional features extend the application spectrum

and increase comfort and safety

Compact, manoeuvrable

and weight-optimized

• Overall length 17.4 m, carrier 15.3 m long

• Large overhang angles, front up to 17°, rear up to 19°

• Smallest turning radius by 5-axle steering

(13.1 m over carrier)

• Axle load equalization (12 t) due to hydropneumatic

suspension ”Niveaumatik”

• In addition to service and parking brake, the following

sustained-action brakes are part of the standard equipment

for safe travel: retarder in the automatic transmission and

engine brake as exhaust brake with Liebherr auxiliary brake

system by valve control (ZBS)

Variable drive and steering concept

• Standard 5-axle steering, 5th and 6th axle are also steerable

independant from axles 1 – 3. During crab steering/diagonal

displacement, axles 3 and 4 are raised hydraulically

• Drive 12 x 6, axles 1, 5 and 6 are driven

• Drive 12 x 8, axles 1, 4, 5 and 6 are driven, 4th axle activatable

for off-road travel

• Automated gear system ZF-TC-TRONIC with converter and

retarder; 12 forward and 2 reversed speeds, automated

control

• Reduced fuel consumption due to a great number of speeds,

sensitive maneuvering due to converter

• Robust transfer case with transfer differential

• Driving axles with differential locks for transverse locking in

off-road ratio

Setting crane on outriggers –

quick, convenient and safe

• Supporting basis 8.84 m x 8.5 m or 8.84 m x 5.58 m

• Fixed lightweight supporting pads (plastic) with lateral

compensation

• Supporting rams with 600 mm travel

• Level control of supporting system, all-automatic levelling

of the crane during the supporting procedure by “push-

button control”

• 2 x 9° lateral inclination even with locked suspension

• Inclinometer (electronic inclination indicator) with two displays

on the carrier and one display on the LICCON monitor in

the crane cab

• 2 supporting force indicators on the control panels on the

carrier and on the LICCON monitor

• Operation of the outrigger system in accordance with the

rules for the prevention of accidents

control block

LICCON

display

screen

luffing ram

single-action

telescoping

ram with

hydraulic

interlocking

device

control levers

3 variable

displacement

pumps

Liebherr Diesel engine D934L A6

transmitters

Liebherr

slewing gear

1 variable

displacement

pump

sensors

Liebherr

hoist winch I

Liebherr

hoist winch II

engine

control

Liebherr

slewing gear

LICCON-

control

15,29

17.41

2.13

4.

0

19°

17°

16.00 R 25 12 t

12 t

12 t 12 t

12 t 12 t

600

8.

5

5.

58

3.

0

6.

56

8.86

R=1

1.40

0.6

R

=

6

.4

2

R=13

.05

R=14

.14

13

2

LTM 1250-6.1

LTM 1250-6.1