Powerful crane drive, With proven components – Liebherr LTR 1100 User Manual

Page 13

LTR 1100

13

The central greasing

• Standard central greasing device

for slewing bearing, boom bearing,

luffing cylinder and winch bearing

• Even supply of grease

• Filling quantity visible at any time

in transparent reservoir

With proven components

The drive components for the crane operation are designed for high perform-

ance and provide for sensitive and precise handling of the load. They are spe-

cially tuned for the crane operation and proved in severe long-term tests.

• Crane engine: 4-cylinder Liebherr turbo diesel engine, 129 kW/175 HP

at 1800 rpm, max. torque 815 Nm at 1100 – 1500 rpm, optimized fuel

consumption by electronic engine management

• Diesel-hydraulic crane drive, open hydraulic circuits with electric

„LOAD SENSING“-control, 4 working motions simultaneously possible.

• Electric/electronic SPS-crane control via the LICCON-computer system

• Slewing gear reversible from open to hydraulically locked, so the slewing

motion can be optimal adapted for the different operation conditions, e. g.

sensitive for installation work or fast for cycle work

• In-house fabricated Liebherr winches, 88 kN rope pull at the outer layer,

less reeving necessary due to high line pull

Powerful crane drive

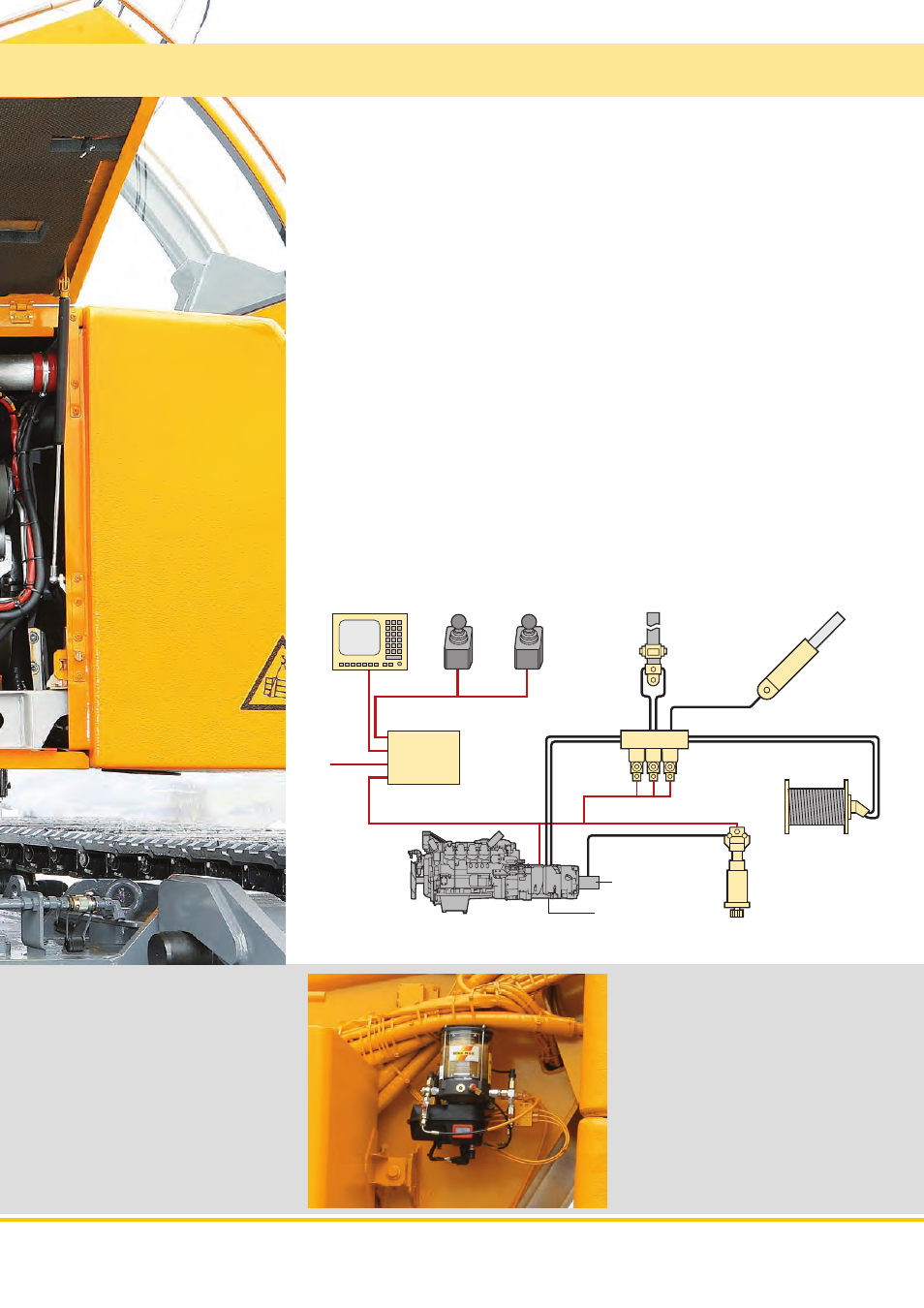

Single stage

telescoping

cylinder with

hydraulic

locking

Luffing cylinder

Liebherr

hoist winch

Liebherr

slewing gear

Gear type pump

Double variable axial

piston pump

Liebherr

diesel engine

Sensors

LICCON

control

Control block

Control

sensor

LICCON-

monitor

The slewing gear

• Liebherr planetary gearbox,

spring loaded multi disk brake

• Reversible open or hydraulically

locked as standard

• Slewing speed from 0 – 1.8 min

-1

infinitively variable

• 5 stages between 10 % and

100 % preselectable