Liebherr LTM 1160-5.1 User Manual

Page 8

9

8

LTM 1160-5.1

LTM 1160-5.1

LSB 3

LSB 1

CAN-Bus

3a

8

1

2

2a

1a

22

LSB 1

15

6

5

LSB 1

18

16

17

7

23

3

CAN-Bus

LSB 4

CAN-Bus

20

19

4

11

LSB 2

4a

14

13a

12

9

21

21

10

13b

7

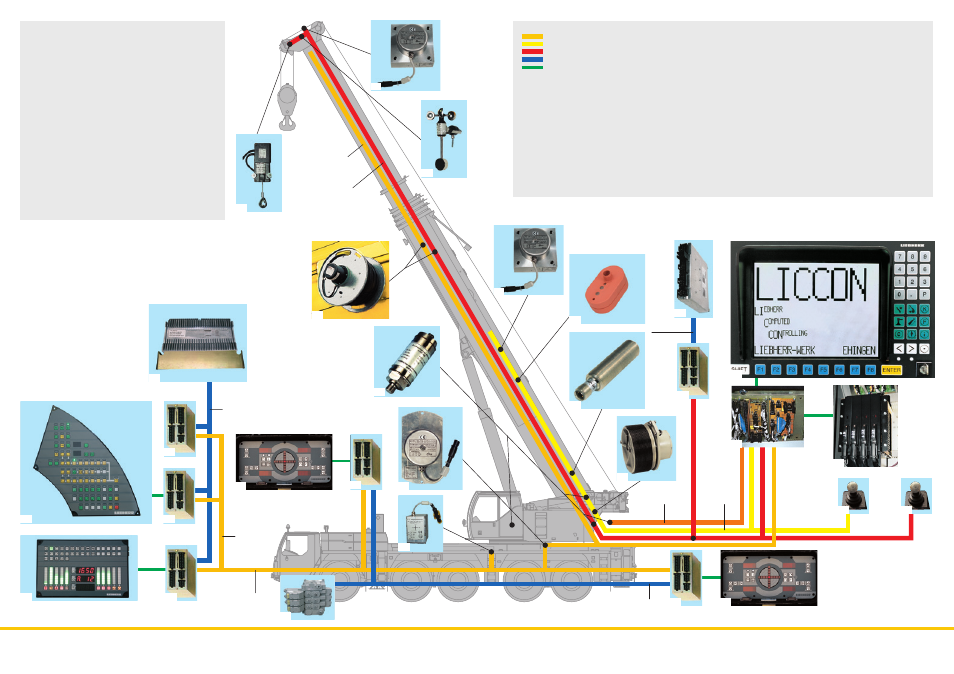

Tilt angle sensor for automatic leveling

8

Rotation sensor in slipring unit

9

Connection to Liebherr system bus (LSB 1, 2, 3, 4)

10

LICCON central unit

11

LICCON monitor in crane cab

12

Length sensor and cable drum/energy cable for

interlocking gripper/telescopic boom

13 a Inductive sensors (6 x)

13 b Track sensors (2x)

14

Angle sensor on boom pivot section

15

Cable drum for items 16, 17, 18

16

Wind sensor

17

Hoisting limit switch

18

Angle sensor

19

Input/output module for electronic control of diesel engine

(superstructure), air flap, fan clutch, exhaust flap valve

20

Injection pump control – Liebherr diesel engine

(superstructure)

21

Control sensor

22

Pressure sensor (4 x) for output management and LMB

(safe load indicator)

23

Valve for active rear-axle steering

Legend:

LSB - Liebherr system bus 1

LSB - Liebherr system bus 2

LSB - Liebherr system bus 3

CAN - Busses

SCI - Serial Communication Interface

1 Input/output module for control of the suspension, Liebherr

diesel engine, automatic transmission, control functions,

compressed air monitoring for brake functions

1a Instrument panel key unit in driver’s cab

2 Input/output module for differential locks, display functions

2a Instrument panel key unit in driver’s cab

3 Input/output module for outrigger system - right

3a Control unit for outrigger system - right

4 Input/output module for outrigger system - left

4a Control unit for outrigger system - left

5 Input/output module for engine brake, cruise control,

speed holder, electronic control of diesel engine

(right steering column switch) and automatic transmission

6 Control of Liebherr diesel engine (chassis) and

automatic transmission

• Electric and electronic components are interconnected by

the latest data bus transmission technology

• Instead of the traditional electric wiring, data transmission

to the individual function blocks is performed digitally along

just a few data cables, thus improving reliability thanks to

a much-reduced number of contacts

• Bus systems of Liebherr’s own manufacture (LSB), specially

suited to mobile crane requirements

• Diesel engine and automatic transmission are controlled by

a CAN data bus. All-electronic driveline management reduces

fuel consumption and exhaust emissions

• The chassis and crane electrical systems and all cockpit

functions and the outrigger and boom sensor systems are

interconnected by 4 Liebherr system bus lines

• Control of the function blocks is by I/O modules programmed

by the Liebherr system bus lines. The control intelligence is

integrated into the central LICCON unit

• Comprehensive diagnostic facilities, quick fault localization,

operating error display

• Programs for functional test of keyboard and display unit

and for testing the engine and transmission management

control units, additional Liebherr brake system, hydraulic

fan, hydraulic suspension and outrigger control panels

• This new data bus technology greatly enhances the

functionality and efficiency of the mobile crane