Liebherr LTM 1160-5.1 User Manual

Page 4

9

4

LTM 1160-5.1

LTM 1160-5.1

700

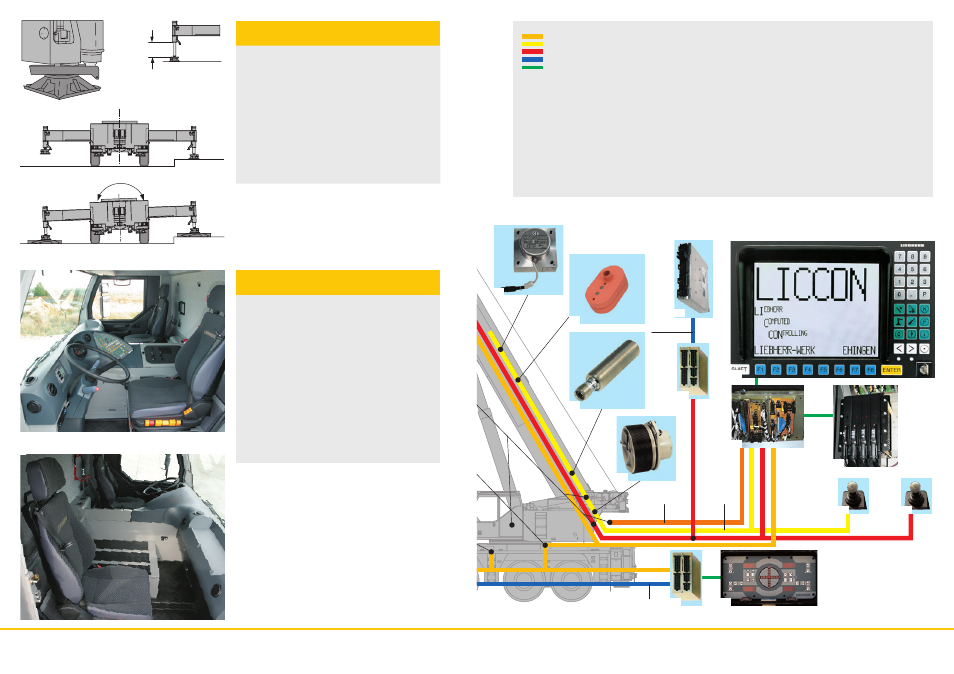

CAN-Bus

LSB 4

CAN-Bus

20

19

4

11

LSB 2

4a

14

13a

12

9

21

21

10

13b

• Variable support base width

Outriggers retracted

Support base area 5.0 m x 7.9 m

Support base area 7.5 m x 7.9 m

• Fixed support pads with splash guard

for protection against dirt

• Support jack extension range up to 700 mm

• Self-leveling of the outriggers, fully-automatic leveling of the

crane by pushbutton during the supporting procedure

• 2 x 9° lateral inclination of crane chassis and superstructure

• Control panels at either side of the chassis with foil-covered

keyboard and electronic angle indicator, pushbuttons for

ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with the

accident prevention regulations

• Illumination of the support area by 4 built-in lights

Supporting crane on outriggers –

quick, convenient and safe

• Modern, comfortable operator’s cab of highly efficient,

convincing design, corrosion-resistant sheet steel

construction, cataphoretic dip-primer coating, resilient rubber

front mountings, hydraulic damping at rear, sound and heat

absorbent interior paneling

• Safety glass all-round, sunproof green-tinted windshield and

side windows for heat absorption, electric window lifters

• Ergonomically correct arrangement of controls and displays

for safe and convenient handling for long periods

• Digital display and key-panel units interconnected with the

functional blocks by data bus technology

• Air-sprung driver’s seat with pneumatic lumbar

support and head restraint

• Steering wheel adjustable for height and angle

• Heated, electrically adjustable outside mirrors

• Seat belts for driver and co-driver

• 3 windshield wipers with automatic wipe/wash system and

intermittent-wipe setting

• Delayed switch-off of interior lighting

• Various storage shelves and compartments

• Preparation for radio

Comfortable, highly efficient

operator’s cab

7

Tilt angle sensor for automatic leveling

8

Rotation sensor in slipring unit

9

Connection to Liebherr system bus (LSB 1, 2, 3, 4)

10

LICCON central unit

11

LICCON monitor in crane cab

12

Length sensor and cable drum/energy cable for

interlocking gripper/telescopic boom

13 a Inductive sensors (6 x)

13 b Track sensors (2x)

14

Angle sensor on boom pivot section

15

Cable drum for items 16, 17, 18

16

Wind sensor

17

Hoisting limit switch

18

Angle sensor

19

Input/output module for electronic control of diesel engine

(superstructure), air flap, fan clutch, exhaust flap valve

20

Injection pump control – Liebherr diesel engine

(superstructure)

21

Control sensor

22

Pressure sensor (4 x) for output management and LMB

(safe load indicator)

23

Valve for active rear-axle steering

Legend:

LSB - Liebherr system bus 1

LSB - Liebherr system bus 2

LSB - Liebherr system bus 3

CAN - Busses

SCI - Serial Communication Interface

1 Input/output module for control of the suspension, Liebherr

diesel engine, automatic transmission, control functions,

compressed air monitoring for brake functions

1a Instrument panel key unit in driver’s cab

2 Input/output module for differential locks, display functions

2a Instrument panel key unit in driver’s cab

3 Input/output module for outrigger system - right

3a Control unit for outrigger system - right

4 Input/output module for outrigger system - left

4a Control unit for outrigger system - left

5 Input/output module for engine brake, cruise control,

speed holder, electronic control of diesel engine

(right steering column switch) and automatic transmission

6 Control of Liebherr diesel engine (chassis) and

automatic transmission