Crane drive with field-proven components, Winch technology by liebherr, Counterweight assembly – just a matter of minutes – Liebherr LTM 1400-7.1 User Manual

Page 7

PN 1400-7.1 DEFISR.fh11 24.07.2007 10:48 Uhr Seite 6

Probedruck

C

M

Y

CM

MY

CY CMY

K

7

6

LTM 1400-7.1

LTM 1400-7.1

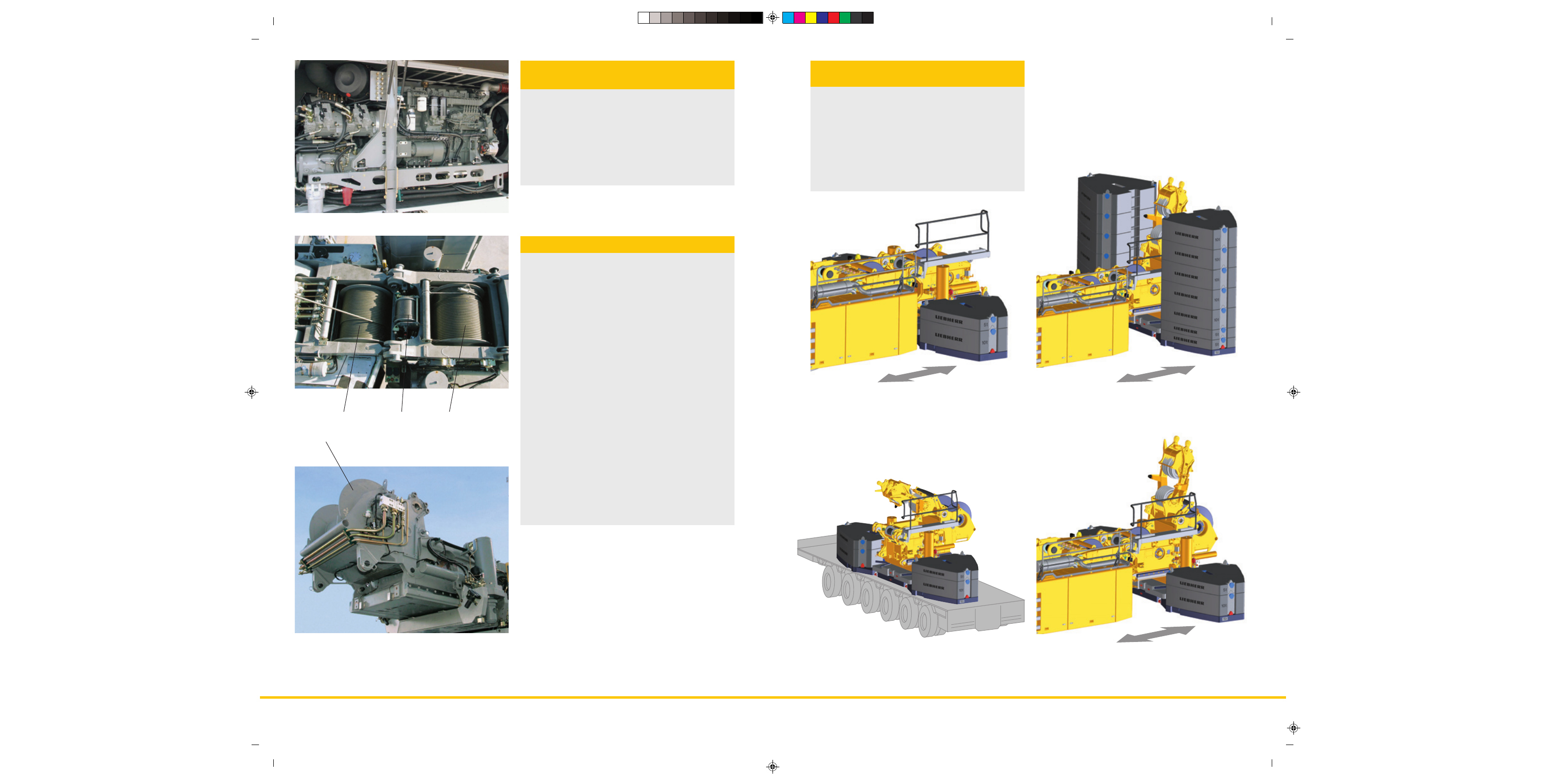

• Crane engine: 6-cylinder Liebherr turbo-charged Diesel engine

type D936L A6 of 240 kW/326 h.p, exhaust gas emissions

in accordance with the directives 97/68/EG stage 3 and

EPA/CARB Tier 3, robust and reliable, electronic engine

management, optimated fuel consumption, exhaust gas

system of special steel

• Hydraulic system with 5 variable axial piston pumps with

servo-control and capacity regulation, auxiliary pumps for

central feeding and ventilator drive, electric driven oil cooler

• Standard high-efficiency noise absorption of the diesel-

hydraulic crane drive

Crane drive with field-proven

components

• Self-manufactured Liebherr winches (1, 2 and 3) with special

grooving, with incorporated planetary gears and spring-

mounted multi-disk brakes as static brakes

Winch 1

main hoist gear

Winch 2

auxiliary hoist gear, required for 2-hook operation with luffing

lattice jib

Winch 3

for variation of the luffing lattice jib

Auxiliary winch

for reeving of the hook block and for the erection of the lattice

luffing jib

• Drive of the hoist gear within a "closed oil circuit", i.e. during

lowering of the load, the oil motor is propping itself up on

the variable displacement pump due to the closed oil circuit

(hydraulic shaft). The potential energy is not converted into

heat, but can be re-employed for an additional movement.

Besides a saving in fuel, the hydraulic oil is less thermically

exposed than in an "open oil circuit"

• Axial-piston variable displacement motor of own manufacture,

specially laid out for crane operation, exposed to tough

fatigue test and field-proven

• Display of the rotary motion of the winch on the LICCON

display screen

• Non-rotating hoist rope, standard rotation absorber

• Video control of the winches (standard in conjunction with

the jib variation winch)

Winch technology by Liebherr

• 140 t total counterweight, 100 t basic counterweight,

40 t additional counterweight

• Hydraulic ballasting device on the counterweight frame

• "60-t-package" of just 3 m transport width, mountable by

one lift

• Hoist gear 2 fitted to the counterweight frame

• Jib variation winch (winch 3) to be pinned on the counterweight

frame

• The counterweight radius can be reduced from 6.6 m

to 5.6 m by the displacement of the entire counterweight

• Reeving winch (auxiliary winch) on the counterweight frame

as standard equipment

Counterweight assembly – just a

matter of minutes

Partial counterweight, radius 5.6 m

140 t total counterweight, radius 6.6 m

60 t-package with winch 3

Luffing jib mode, counterweight radius 5.6 m

or 6.6 m

Winch 1

Winch 2

Auxiliary

winch

Winch 3