Multi variable boom configuration system – Liebherr LTM 1400-7.1 User Manual

Page 4

PN 1400-7.1 DEFISR.fh11 24.07.2007 10:48 Uhr Seite 4

Probedruck

C

M

Y

CM

MY

CY CMY

K

4

9

LTM 1400-7.1

LTM 1400-7.1

10 m

20 m

30 m

40 m

50 m

60 m

70 m

80 m

90 m

100 m

110 m

120 m

130 m

T/TY

TF / TYF

TN / TYN

600

0 m

38°

38°

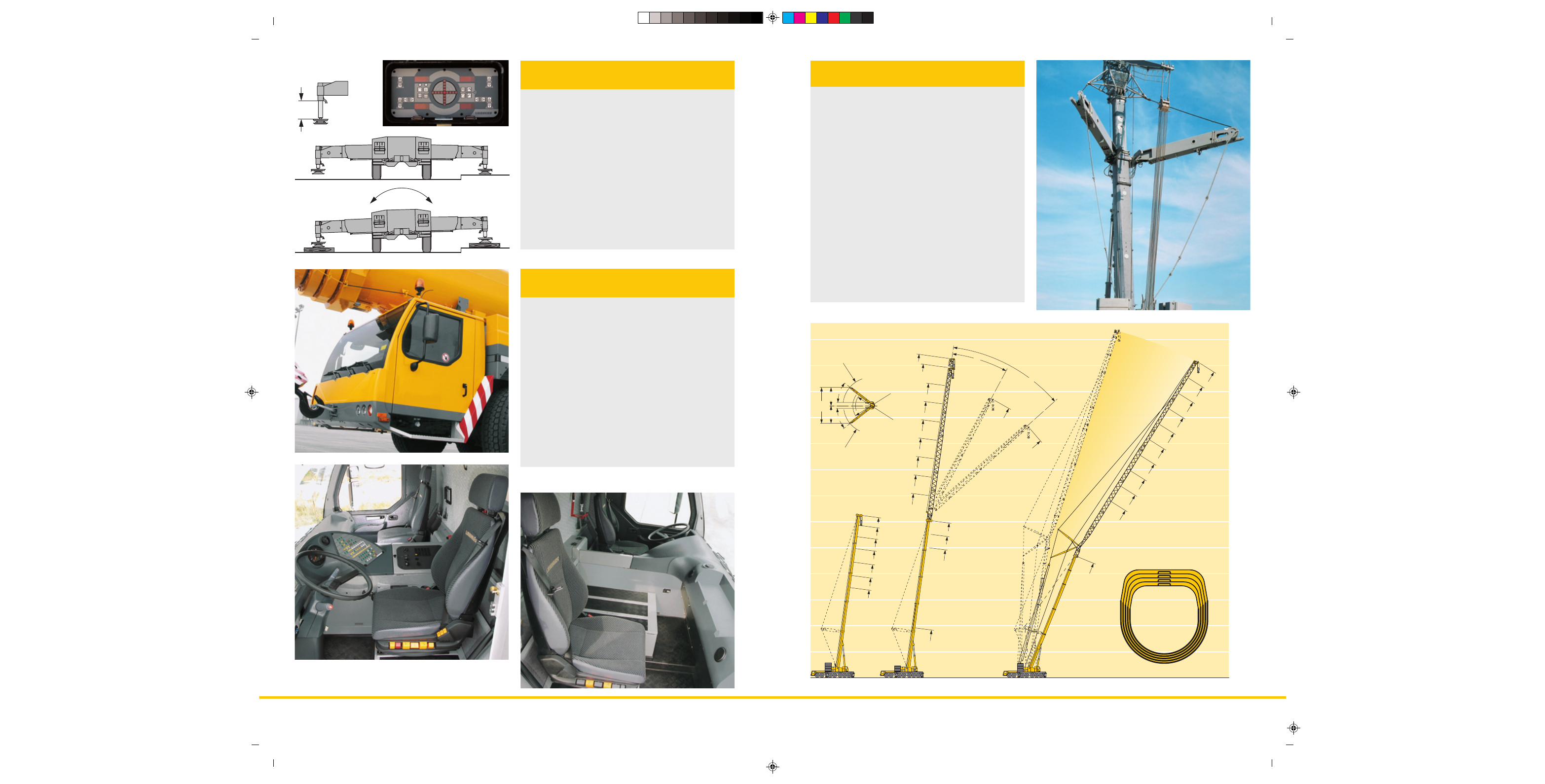

• Modern driver’s cab of outstanding functionality and

convincing design. Corrosion resistant sheet steel version,

cataphoretic dip-primed, front section mounted on shock

absorbers, rear damped hydraulically, internal sound and

heat absorbing panelling

• Safety glas all-round, greenish tinted front and side windows

for heat insulation, electric window lifters

• 3 automatic windscreen washers/wipers with intermittent

control

• Heated and electrically adjustable outer rear mirrors

• Air-cushioned driver’s and co-driver’s seat with headrests,

driver’s seat with pneumatic lumber support

• Safety belts for driver’s and co-driver’s seat

• Height and inclination adjustable steering wheel

• Standardized, digital operating and control instruments

arranged ergonomically for safe and convenient handling,

arranged operator-friendly in a half-round shape

• Digital display and keyboard units interconnected with the

functional blocks by data bus technology

• Additional heater with engine preheating

Comfortable driver’s cab of

outstanding functionality

• Telescopic boom T, 15.4 m – 60 m

• Telescopic boom guying system TY, 5.25 m wide "spacer"

for TYSF and TYSN mode

• Fixed lattice jib TF (TYSF), 7 m - 56 m, mountable at 0°, 20°

or 40° on the 15.4 m – 60 m long telescopic boom

• Lattice luffing jib TN (TYSN), 14 m – 84 m, mountable on the

15.4 m – 56.4 m long telescopic boom

• Continuous load capacity interpolation during luffing of the

boom configuration TN (TYSN) between 82° and 68° telescopic

boom inclination

• Intermediate sections TF and TN equipment are identical,

intermediate sections can be slid into one another for

transportation

• Jib A-frames with T-adapter and N-base section form a

complete mounting/transport unit and can be fitted with just

4 pins

• Easy-to-rig stay rods which remain on the intermediate

sections during transportation

• Auxiliary winch on the counterweight frame for easy reeving

of the hoist and luffing ropes

• Rigging of the jib can be performed in suspended condition

on restricted sites

• Winch 2 for 2-hook operation on the lattice jib

• Winch 3 for jib variation. The variation winch forms one unit

with the variation block. The variation rope remains reeved

during transportation.

Multi variable boom configuration

system

• Supporting basis: 10 m x 9.5 m or 10 m x 6.23 m

• Fixed suporting pads with lateral compensation

• Supporting rams with 600 mm travel

• Level control of the outriggers, all-automatic levelling of the

crane during the supporting procedure by "push-button

control"

• 2 x 9° lateral inclination of the carrier, thus simple underlay

of the supporting pads

• Inclinometer (electronic inclination indication), two displays

on the carrier and a display on the LICCON monitor in the

crane cab

• 2 supporting force indicators on the control panels on the

carrier and on the LICCON display screen to indicate the

supporting force on the supporting rams

• 4 projectors for the illumination of the supporting zone

• Axle locking (blocking of the suspension for the displacement

with equipment) controllable from the driver’s cab

• Operation of the outrigger system in accordance with the

rules for the prevention of accidents

Setting crane on outriggers –

quick, convenient and safe

oviform boom profile

60 m

56.5 m

51.4 m

46.3 m

41.1 m

36 m

30.8 m

56.6 m

51.4 m

46.3 m

15.4 m

F 49 m

F 42 m

F 35 m

F 28 m

F 21 m

F 14 m

F 7 m

F 49 m

F 49 m

N 84 m

N 77 m

N 70 m

N 63 m

N 56 m

N 49 m

N 42 m

N 35 m

N 28 m

N 21 m

46.3 m

T 60 m

F 56,6 m

T 56.6 m

F 56 m

20°

40°

82°

68°

6.4

6.2

12.6

R = 10

R = 6.6

R = 5.6

R = 9.8