Curb wheel adjustment, Lubrication – Briggs & Stratton 592 User Manual

Page 10

10

Trimming

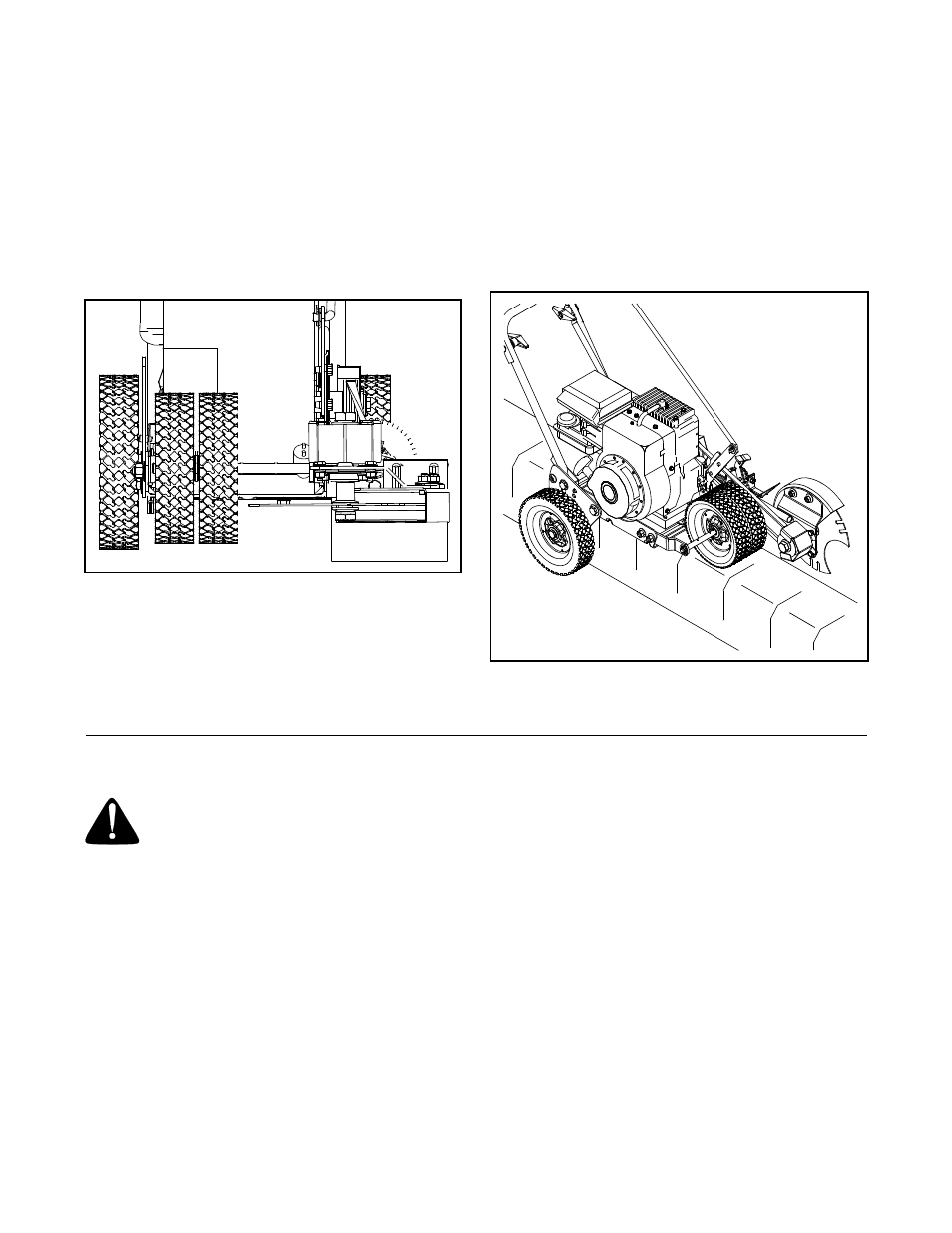

Placing the blade angle adjustment lever in the notch

furthest to the left will put the spindle assembly at a

proper angle for trimming with the edger as illustrated in

Figure 13.

IMPORTANT:

When the spindle assembly is rotated

counter-clockwise (putting the blade closer to a

horizontal position), it IS necessary to change the

position of the front, left wheel to prevent the edger

blade from striking the wheel. See

Front Wheel Adjustment

earlier in this section.

Figure 13

Curb Wheel Adjustment

The right, rear wheel of the edger can be lowered into

one of five positions to ease the task of edging along a

curb.

To adjust the height of the curb wheel, proceed as

follows:

•

Perform the

Front Wheel Adjustment

for curb wheel

operation as instructed earlier in this section.

•

Lower the right, rear wheel by moving the curb

height adjustment lever slightly to the left.

•

Place the right, rear wheel into an applicable

position in relation to the height of the curb to be

edged along.

•

Release the curb height adjustment lever to lock

the wheel in position. See Figure 14.

Figure 14

SECTION 6: MAINTAINING & SERVICING THE EDGER

WARNING: Disconnect the spark plug wire

and ground against the engine before

performing any adjustment, repairs or

maintenance. Refer to Figure 2.

Lubrication

Engine

Refer to the

Service, Storage & Specifications

section of the

Briggs & Stratton Owner/Operator Manual packed with

the edger for all engine-related service specifications.

Wheels & Front Axle

Lubricate the wheels and front axle at least once a

season with a light oil. Also if the wheels are removed

for any reason, lubricate the surface of the axle bolt and

the inner surface of the wheel with light oil.

Pivot Points

Lubricate the pivot points on the blade angle

adjustment lever, blade clutch/depth control lever and

curb height adjustment lever with light oil at least once a

season.

Cutting Head Bearings

The two ball bearings in the blade spindle housing are

lubricated and sealed at the factory and require no

lubrication.

Spindle Shaft

Lubricate the two shoulder spacers and the entire area

surrounding the compression spring on the edger’s

spindle shaft with light oil (NOT WD-40) frequently

during the season. Do NOT allow rust to form in this

area. See Figure 15.