Bryant 538J-18-1 User Manual

Page 3

—

3

—

II. RIG AND MOUNT UNIT

A. Mounting on Ground

Mount unit on a solid, level concrete pad. Position unit so

water or ice from roof does not fall directly into unit. Field-

fabricated stacking kits can be used when units are to be

stacked. If conditions or local codes require unit to be fas-

tened to a pad, 6 field-supplied tiedown bolts should be used

and fastened through slots provided in unit mounting feet.

B. Mounting on Roof

Mount unit on level platform or frame at least 6 in. above

roof surface. Isolate unit and tubing from structure.

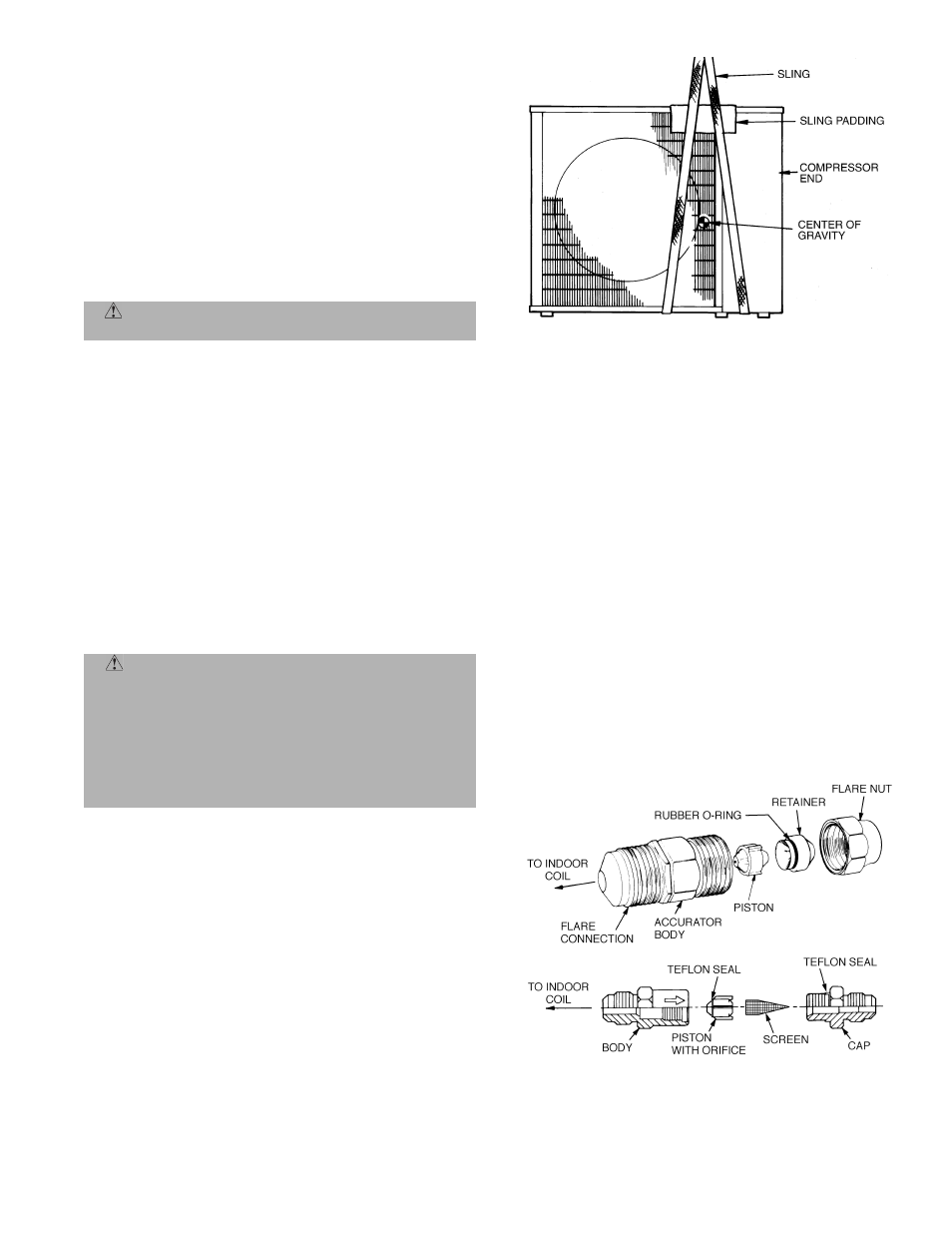

C. Rigging

Keep unit upright. Lift unit using sling. Use cardboard or

padding under sling, and spreader bars to prevent sling

damage to unit. See Fig. 3. See Fig. 2 for center of gravity ref-

erence. Install unit so coil does not face into prevailing

winds. If this is not possible and constant winds above

25 mph are expected, use field-fabricated wind baffle.

NOTE: Accessory wind baffles should be used on all units

with accessory low-ambient control.

Field-fabricated snow stand may be used to raise unit when

operation will be required during the winter. Units may also

be wall mounted using the accessory wall mounting kit.

III. COMPLETE REFRIGERATION PIPING CONNECTIONS

Outdoor units may be connected to indoor units using field-

supplied tubing of refrigerant grade and condition. See

Tables 1A and 1B for correct line sizes. Do not use less than

10 ft (3 m) of interconnecting tubing.

When more than 50 ft (15.2 m) of interconnecting tubing and

more than 30 ft (9.1 m) of vertical lift is used, refer to Part 3

of the System Design Manual for design details, or contact

your local distributor.

If either refrigerant tubing or indoor coil is exposed to atmo-

spheric conditions for longer than 5 minutes, it must be evac-

uated to 1000 microns to eliminate contamination and

moisture in the system.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes so

they do not damage insulation on vapor tube and do not

transmit vibration to the structure. Also, when passing

refrigerant tubes through the wall, seal opening so that

vibration is not transmitted to structure. Leave some slack

in refrigerant tubes between structure and outdoor unit to

absorb vibration. Refer to separate indoor unit installation

instructions for additional information.

A. Check AccuRater® Control

The AccuRater refrigerant control is required for cooling sys-

tem capacity optimization. An AccuRater device with field-

replaceable piston should be supplied with the indoor unit.

Refer to AccuRater metering device table in separate indoor

unit installation instructions to determine the correct Accu-

Rater piston size required for the condenser/evaporator sys-

tem being installed.

Note that one of 2 types of the AccuRater devices can be

used. Use Type A only if Type B is unavailable. See Fig. 4. Do

not interchange components between AccuRater device

types. Matching of outdoor unit with indoor unit may require

field replacement of piston. Replace piston, if required,

before connecting refrigerant lines. Piston replacement

instructions are included in the indoor unit installation

instructions. After system installation is complete, see

Refrigerant Charging section on page 8 to check and/or

adjust refrigerant charge.

The 538J series units may also be installed with units using

a thermostatic expansion valve (TXV). If a TXV is used, be

sure to remove the piston from the indoor coil. See installa-

tion instructions shipped with the TXV for proper position-

ing and adjustment.

CAUTION: Be sure unit panels are securely in

place prior to rigging.

CAUTION: DO NOT BURY MORE THAN 36 IN.

(922 mm) OF REFRIGERANT PIPE IN THE

GROUND. If any section of pipe is buried, there must

be a 6 in. (154 m) vertical rise to the valve connections

on the outdoor unit. If more than the recommended

length is buried, refrigerant may migrate to the cooler,

buried section during extended periods of system shut-

down. This causes refrigerant slugging and could dam-

age compressor at start-up.

Fig. 3 — Lifting Unit with Sling

TYPE B (RECOMMENDED)

NOTE: Arrow on AccuRater body points in free-flow direction, away

from the indoor coil.

Fig. 4 — AccuRater Metering Device Components

TYPE A (FIELD-INSTALLED BYPASS TYPE)