Buhler 65 Series User Manual

Page 31

65 Series Rotary Tiller

31

BOLT TORQUE

CHECKING BOLT TORQUE

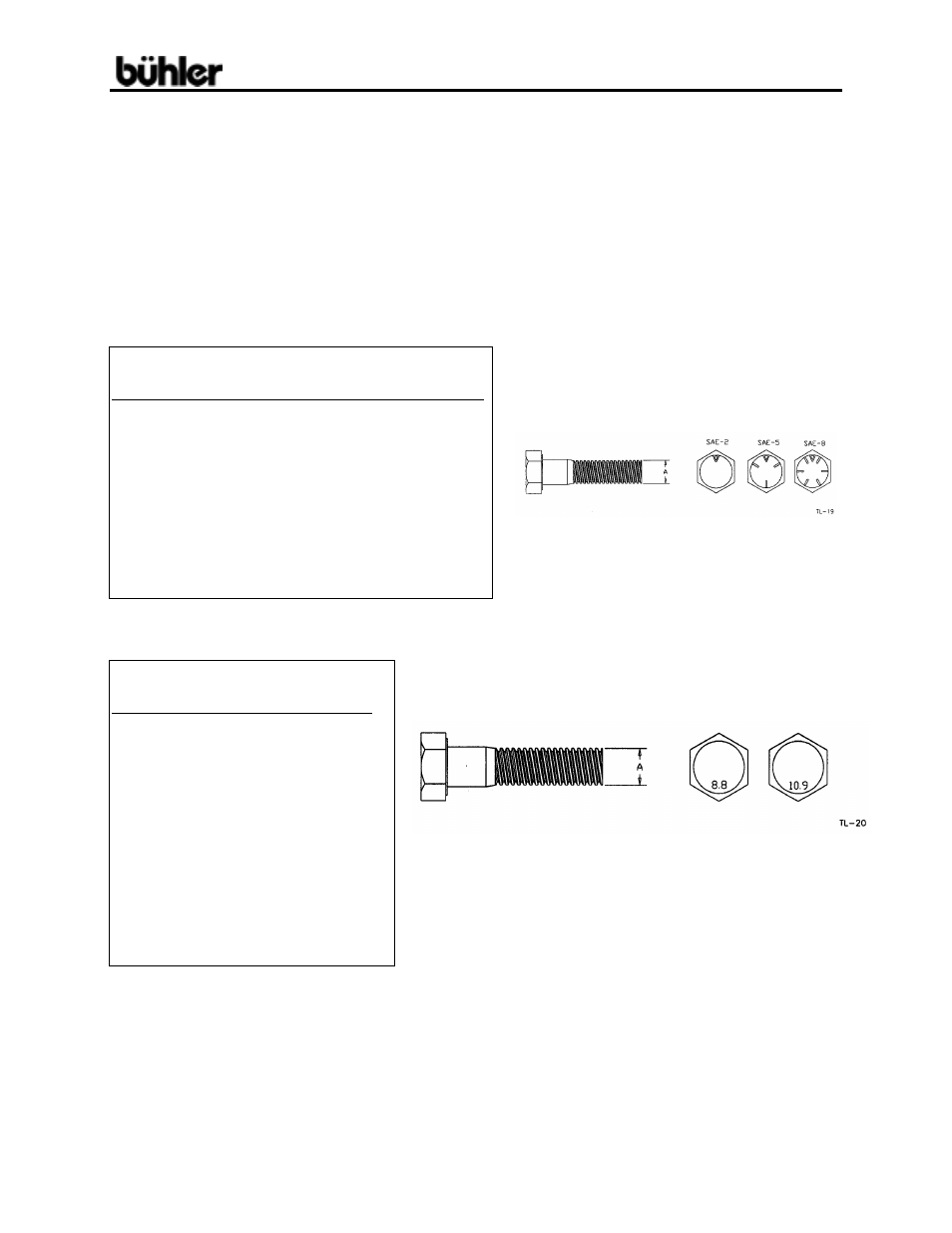

The tables shown below give correct torque values for various bolts and capscrews.

Tighten all bolts to the torques specified in chart unless otherwise noted. Check

tightness of bolts periodically, using bolt torque chart as a guide. Replace hardware

with the same strength bolt.

ENGLISH TORQUE SPECIFICATIONS

Bolt

Bolt

Torque

*

Diameter SAE2

SAE 5

SAE 8

"A" N.m (lb-ft)

N.m (lb-ft)

N.m (lb-ft)

¼” 8 (6) 12 (9) 17 (12)

5/16"

13 (10)

25 (19)

36 (27)

3/8"

27 (20)

45 (33)

63 (45)

7/16"

41 (30)

72 (53)

100

(75)

½” 61 (45) 110 (80) 155 (115)

9/16"

95 (70) 155 (115)

220 (165)

5/8” 128 (95) 215 (160)

305 (220)

¾” 225 (165)

390 (290)

540 (400)

7/8" 230 (170)

570 (420)

880 (650)

1" 345 (225)

850 (630)

1320

(970)

METRIC TORQUE SPECIFICATIONS

Bolt

Bolt

Torque

*

Diameter 8.8 10.9

"A" N.m (lb-ft)

N.m (lb-ft)

M3

.5

(.4)

1.8

(1.3)

M4

3

(2.2)

4.5

(3.3)

M5

6

(4)

9

(7)

M6

10

(7)

15

(11)

M8 25 (18)

35 (26)

M10 50

(37)

70

(52)

M12

90

(66)

125

(92)

M14

140

(103)

200

(148)

* Torque value for bolts and cap screws are identified

M16

225

(166)

310

(229)

by their head markings.

M20 435 (321)

610 (450)

M24 750 (553) 1050 (774)

M30 1495 (1103)

2100 (1550)

M36 2600 (1917)

3675 (2710)

Torque figures indicated above are valid for non-greased or non-oiled threads and

heads unless otherwise specified. Therefore, do not grease or oil bolts or cap screws

unless otherwise specified in this manual. When using locking elements, increase

torque values by 5%.