Bush Hog 2175 User Manual

Page 23

21

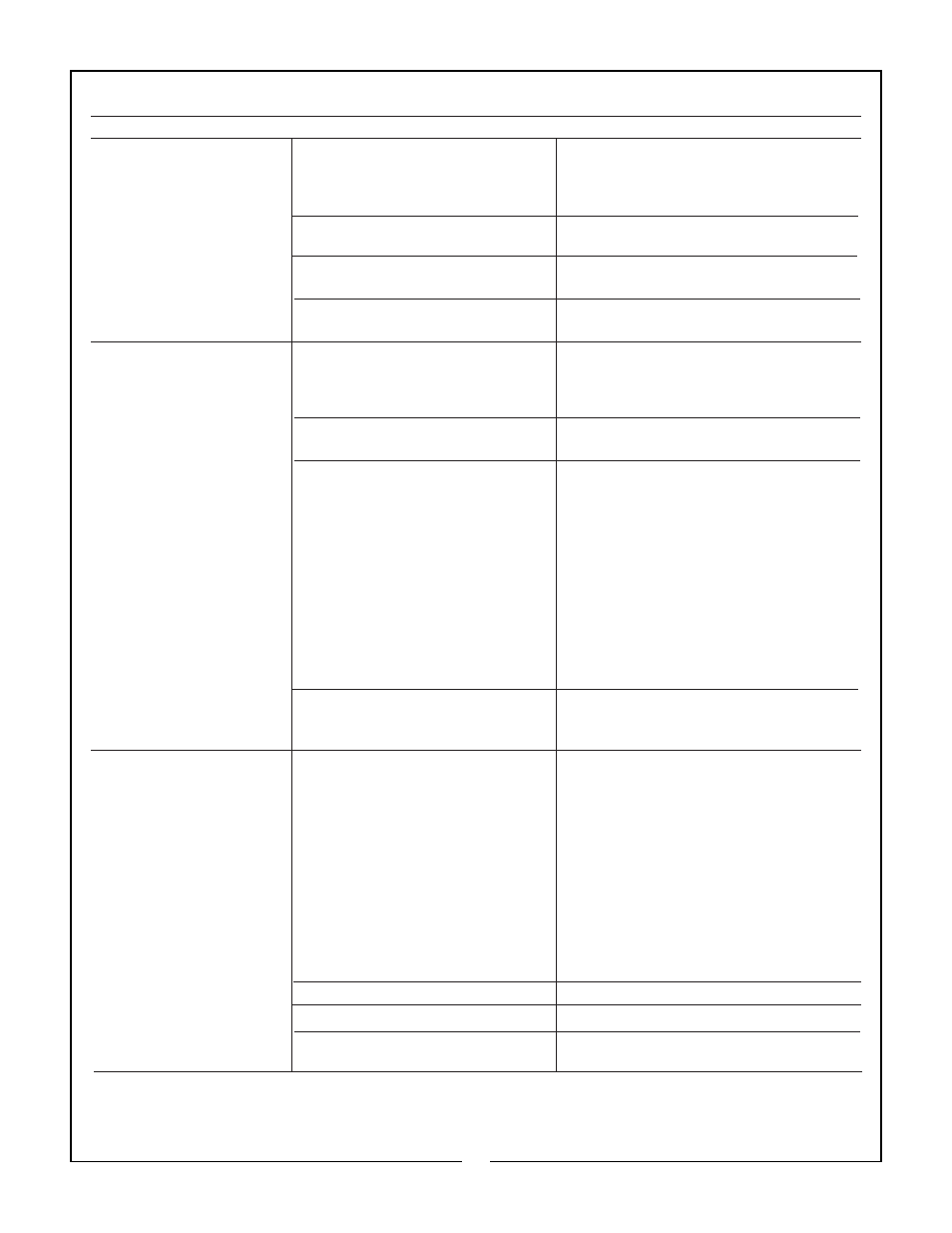

Troubleshooting (Continued)

Problem

Cause

Correction

Leaky cylinders

Oil is bypassing cylinder piston,

Replace or rebuild the cylinder; replace

scored piston, worn piston

damaged parts.

packing, or defective piston

assembly

Scored piston rods and worn

Replace or rebuild the cylinder; replace

guides in cylinder

damaged parts.

Bent piston rod in cylinder

Replace or rebuild the cylinder; replace

damaged parts.

Worn or damaged rod seals on

Repack cylinder. Rebuild cylinder,

cylinder; external leaks

replacing damaged parts as necessary.

Leaky valve

Loose oil line connections,

Tighten all hose connections and

leaks in line or broken lines

replace any damaged O-rings at

leaking O-ring fittings. Check and

replace any damaged hoses and lines.

Excessive back pressure

Relieve condition. Restriction may be

from outlet to reservoir.

Paint on valve spool; sticking

Clean valve spool. Binding is usually

valve spool or scored valve

caused from an over tightened plug,

spool

mounting bolt, fitting in valve body or

tie rod bolt. If a plug or fitting in the

valve body is leaking, do not overtighten

in an effort to stop leak. This will distort

body casting and cause spools to bind.

Instead, the plug and fitting should be

removed from valve body and be

reconnected, using a new O-ring. Do

not apply excessive pressure on

mounting bolts. The rods should be

torqued to 30 ft. lbs. Never force spool.

Ball in anti-cavitation check

Clean anti-cavitation valve carefully,

valve is stuck or not seating

being sure that checks move freely and

properly.

seat properly, or replace cartridge.

Sticky valve spool

Paint on valve spool; sticking

Clean valve spool. Binding is usually

valve spool or scored valve

caused from an over tightened plug,

spool

mounting bolt, fitting in valve body or

tie rod bolt. If a plug or fitting in the

valve body is leaking, do not overtighten

in an effort to stop leak. This will distort

body casting and cause spools to bind.

Instead, the plug and fitting should be

removed from valve body and be

reconnected, using a new O-ring. Do

not apply excessive pressure on

mounting bolts. The rods should be

torqued to 30 ft. lbs. Never force spool.

Bent spool

Replace with new spool section.

Foreign particles

Clean system and valve.

Misalignment of control handle

Check linkage for binding condition.

linkage