Baldor GLC GENERATOR GLC45 User Manual

Page 79

Series GLC A-3

MN2408

Replacement Parts

Continued

Description

Part No.

Description

GLC 80

GLC 100

GLC125

DECAL BONDED NEUTRAL"

LB0300A00

LB0300A00

LB0300A00

DECAL FUSE TYPE & WARNING"

LB0300A01

LB0300A01

LB0300A01

DECAL, CONTROL PANEL

LB0094B60

LB0094B60

LB0094B60

PLACARD, REMOTE START"

LB0095A42

LB0095A42

LB0095A42

DECAL, BALDOR LOGO,26"

LB0100A27

LB0100A27

LB0100A27

DECAL, BALDOR LOGO

LB0100A29

LB0100A29

LB0100A29

DECAL, DANGER-HIGH VOLTAGE

LB0094A11

LB0094A11

LB0094A11

DECAL, WARNING, AUTO START

LB0094A30

LB0094A30

LB0094A30

PLACARD, LINE"

LB0095A07

LB0095A07

LB0095A07

PLACARD, LOAD"

LB0095A08

LB0095A08

LB0095A08

PLACARD, NEUTRAL"

LB0095A15

LB0095A15

LB0095A15

PLACARD, L1"

LB0095A16

LB0095A16

LB0095A16

PLACARD, L2"

LB0095A17

LB0095A17

LB0095A17

PLACARD, L3"

LB0095A18

LB0095A18

PLACARD, A.C. CONNECTION"

LB0095A51

LB0095A51

LB0095A51

PLACARD, GROUND"

LB0095A37

LB0095A37

LB0095A37

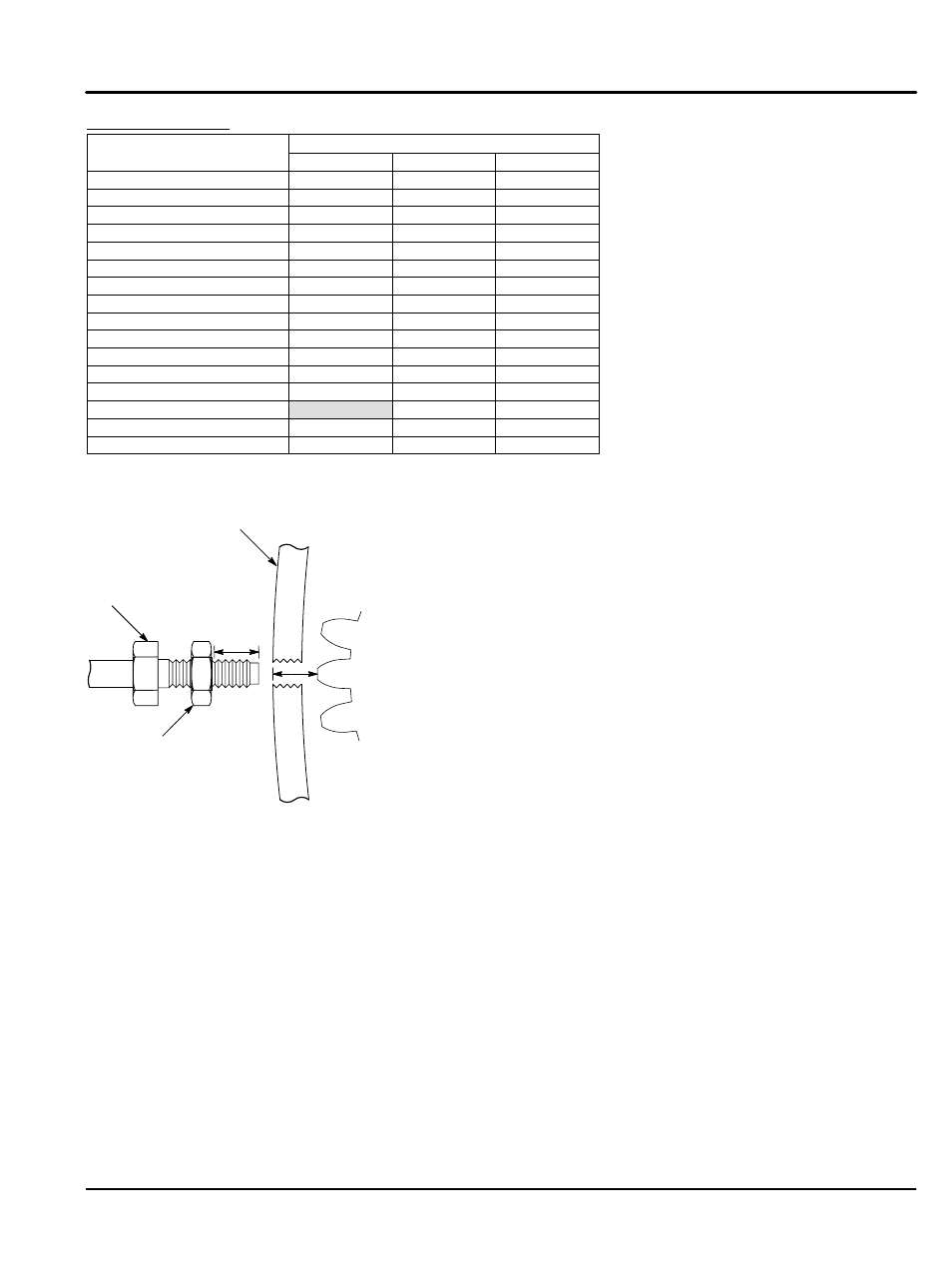

Figure A-1 Magnetic Pickup Replacement

d

d+

Flywheel

Gear Ring

Flywheel

Housing

Magnetic

Pickup

Cable

Jam

Nut

This procedure is intended to help during the replacement of a Magnetic Pickup speed

sensor.

1. Ensure that the battery is disconnected from the generator set prior to performing any

service work on the unit. Remove the old Magnetic Pickup sensor.

2. Ensure that a tooth on the flywheel gear ring is centered directly in the hole for the

Magnetic Pickup. If not, rotate the engine/generator to center a tooth by placing a

socket on the engine main crank pulley.

DO NOT insert a screwdriver into the hole for the magnetic pickup as the threads

in the flywheel housing can be damaged. DO NOT use the generator cooling fan

to rotate the engine/generator. The fan may crack and will have to be replaced.

3. With a tooth centered in the hole, measure the distance d" from the top of the tooth to

the outside top of the flywheel housing. Set the jam nut on the magnetic pickup slightly

beyond that measurement d+" to ensure that the magnetic pickup fully threads into the

housing. (If the flywheel housing or magnetic pickup threads are damaged, the

magnetic pickup may seem to have bottomed out when it stopped due to bad threads.)

4. Thread the magnetic pickup into the flywheel housing until it bottoms out on the

flywheel tooth.

5. Back the magnetic pickup out 1/2 turn and tighten the jam nut to the flywheel housing.

Note: The 1/2 turn out is very important. Too little can ruin the magnetic pickup and

create extra cleanup work. Too much can result in poor operation.

6. Verify proper operation. (1.3 VAC while cranking)

7. Apply a drop of wicking fastener adhesive to the locking nut of the magnetic pickup.

(Loctite, Permabond, etc.)