Uni-lign, Ac-11 – Sheffer LA SERIES User Manual

Page 12

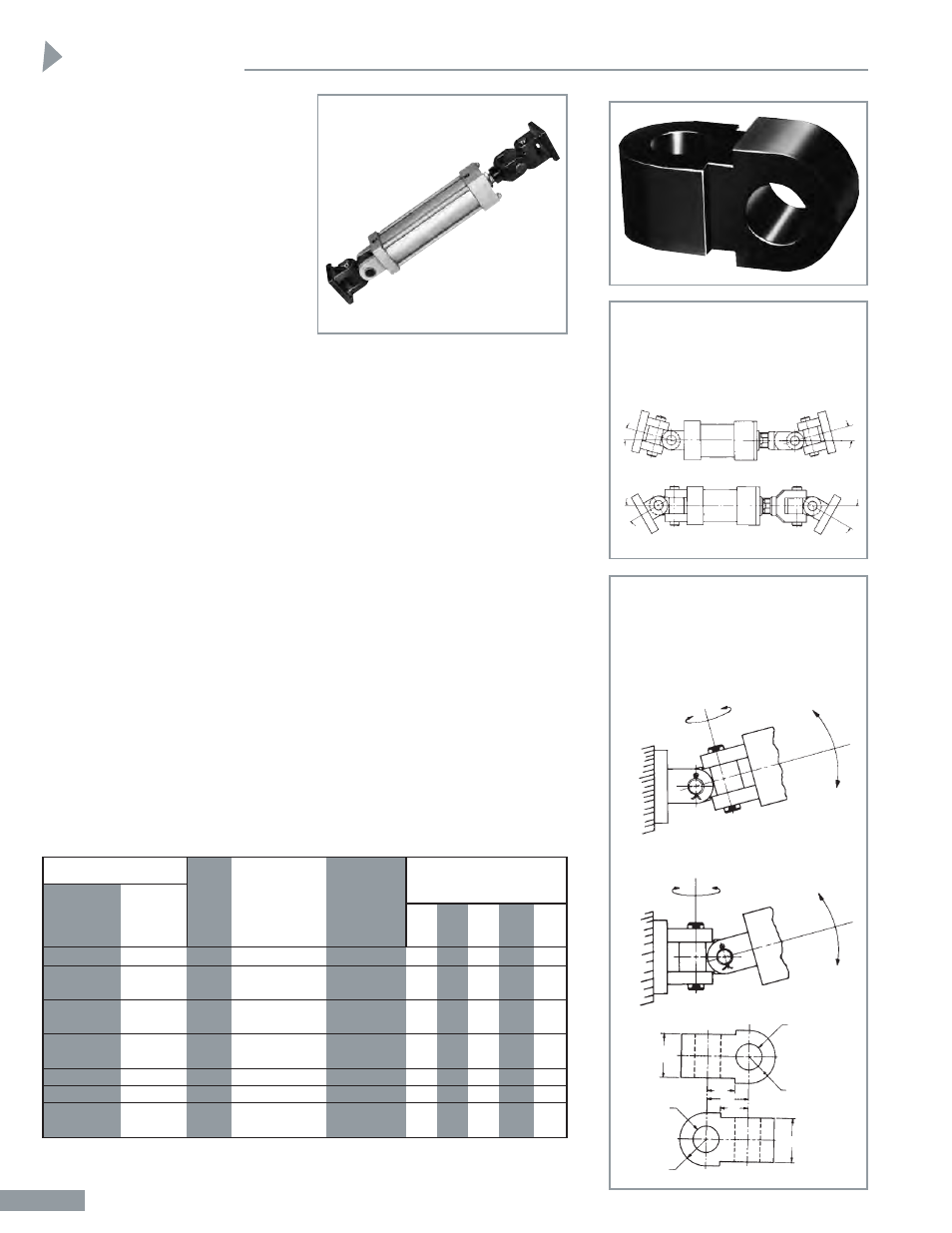

Reduces Misalignment

Problems!

Much effort has been made by many

to relieve, or eliminate the side

loading of cylinders created as a result

of misalignment. It is, of course,

almost impossible to get perfect

alignment and since the alignment of

the cylinder has a direct bearing on its

life, the efforts have been well worth

while.

A spherical bushing used by The

Sheffer Corporation and most

everyone else in the cylinder industry,

for various applications, is excellent

and serves a very useful purpose. It

does, however, have some very

definite limitations. First and

foremost among these is its inability,

with the limited space available, to

take the loads that the cylinder is

capable of producing. The second

deficiency of the spherical bushing or

bearing is that it is limited to a

maximum misalignment of five

degrees and can act as a complete

hinge in one direction only.

With the Sheffer UNI-LIGN most,

if not all, of these limitations have

been eliminated. For instance, fifteen

degrees each side of center is a

reasonable angular misalignment at

the pins, at the cylinder clevis and the

rod clevis, increasing by three times

the capabilities of the spherical

bushing, plus providing maximum

load carrying capabilities. It is

recommended that not more than a

thirty degree maximum angle be used

on the pins in the out-board end of

the UNI-LIGN units. However, when

lighter than maximum loads are

encountered, as much as 90 degrees

could be used with complete safety.

All components, pins, UNI-LIGN and

mounting brackets are designed to

take maximum loading of the cylinder

where pin sizes match that of the

clevis mount cylinder. All matching

accessories and clevis mounts for

cataloged cylinders are catalog

standard. Time saved in installation

may very well pay for the entire cost

of the application.

• No special fitting

• Gives freer range of mounting

positions

• Simplifies machine design

requirements

• Reduces cylinder binding and

slide-loading

• Allows universal swivel

• Less critical machining

• Reduces bearing and tube

wear

• Eliminates piston blow-by from

misalignment

• Works with standard mounting

accessories

Dimensions

FOR USE WITH SHEFFER

CLEVIS MOUNT

A & MH

HH

CLEVIS

SERIES

SERIES

UNI-

MOUNTING

ROD

CYLINDERS

CYLINDERS

LIGN

BRACKET

CLEVIS

BORE

BORE

PART

PART

PART

CD

ER

SIZE

SIZE

NO.

NO.

NO.

CB

PIN

RAD.

LR

U

1

1

/

8

1

1

/

8

UL-10

MBC-A30510

CLS-A2043

5

/

8

3

/

8

3

/

8

7

/

16

5

/

8

1

1

/

2

, 2

AND 2

1

/

2

1

1

/

2

UL-14

MBC-A40614

CLS-A1043

3

/

4

1

/

2

1

/

2

35

/

64

7

/

8

3

1

/

2

, 4

AND 5

2, 2

1

/

2

UL-19

MBC-A61020

CLS-A10750

1

1

/

4

3

/

4

3

/

4

51

/

64

1

3

/

16

6, 7

AND 8

3

1

/

4

UL-27

MBC-A81224

CLS-A11000

1

1

/

2

1

1

1

3

/

64

1

11

/

16

10

4

UL-38

MBC-A111632

CLS-A11250

2

1

3

/

8

1

3

/

8

1

7

/

16

2

3

/

8

12

5

UL-49

MBC-A142040

CLS-A11500

2

1

/

2

1

3

/

4

1

3

/

4

1

13

/

16

3

1

/

16

6

UL-58

†MBC-A142040

CLS-A11870

2

1

/

2

2

2

2

1

/

16

3

5

/

8

MBC-A162040

†For A SERIES

MOUNTING INFORMATION

15°

30°

B

B

CB

CD

ER

LR

U

LR

CB

CD

ER

A

A

B

A

A

B

30°

15°

Maximum recommended angular

deviation from center line:

INBOARD PIN-15°

OUTBOARD PIN-30°

A-A – PRIMARY PIVOT PLANE

(FOR AXIAL LOADING OF

CYLINDER)

B-B – SECONDARY PIVOT PLANE

(FOR MISALIGNMENT OF

CYLINDER)

CORRECT

INCORRECT

14

UNIVERSAL ALIGNMENT MOUNTING ACCESSORY

Uni-Lign

1

AC-11

DIMENSIONS