Howard HI-104 Single-Phase Pad Transformer User Manual

Page 33

Document 2.4.96, Revision 0

March, 2013

33

Single-Phase Pad-Mounted Compartmental-Type Distribution Transformers

2. Re-install the handhole cover. Re-install fasten-

ers according to the torque recommendations in

Table 1. After tightening all fasteners, re-torque

each one to ensure proper torque.

3. Pressurize the headspace to 3-4 PSIG and check

for fluid leaks. This pressure should be main-

tained for at least four hours, followed by another

leak check.

Torque Guidelines

Tables 1 through 4 below contain recommended

torque values for tightening various connections on

the transformer. Be aware that connections with gas-

kets and those involving rubber components (such

as high-voltage bushing inserts) will normally relax

after initial tightening.

Do not over-tighten any connection; otherwise,

gaskets might split due to over-compression, and

components might break. Fluid leaks could result if

tank-mounted components are over tightened. Check

with the Howard Industries Transformer Division for

recommended torque values for any devices or con-

nections not listed below. Use the manufacturer’s

recommended torque values for any user-provided

devices.

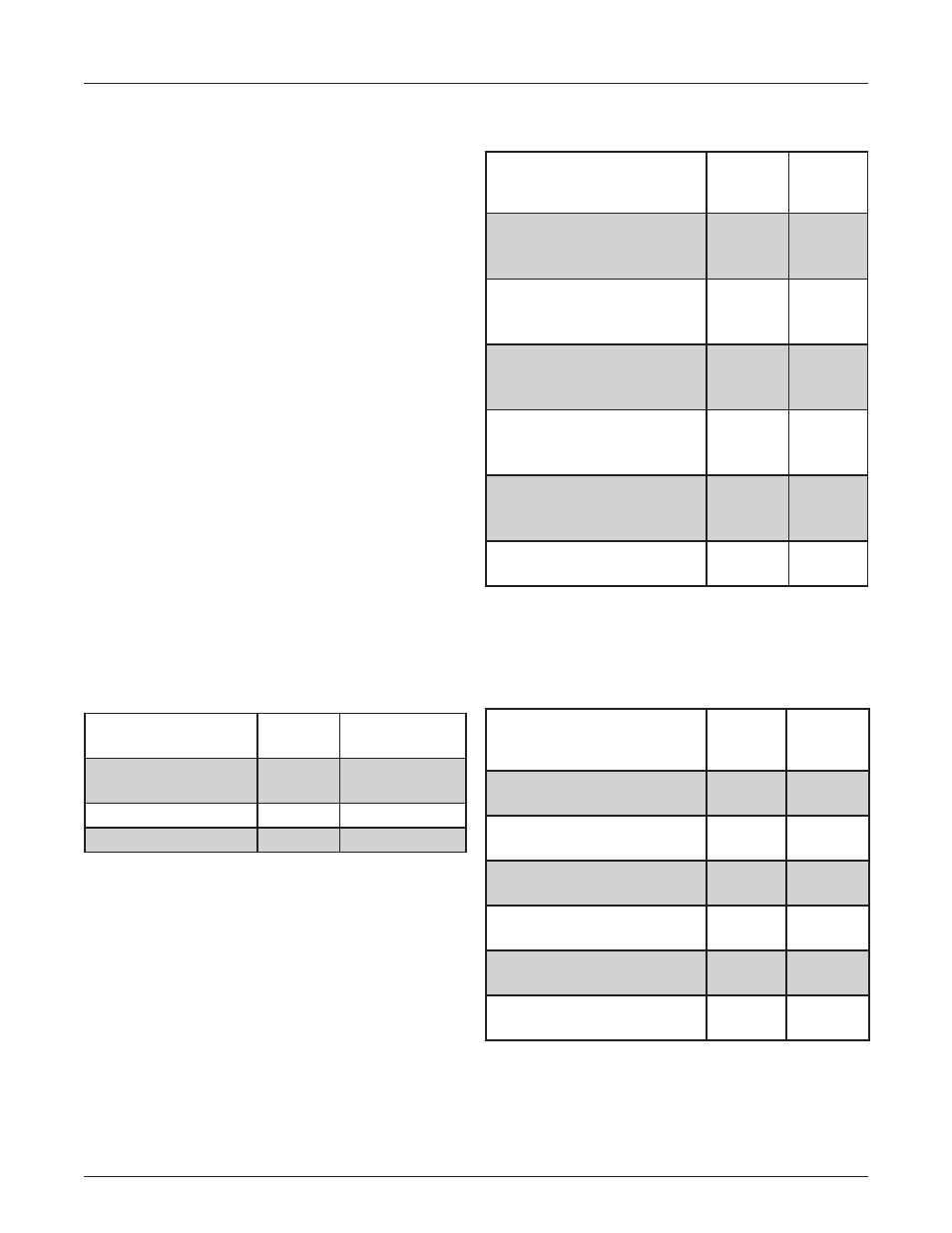

Table 1:

Torque Guidelines for External Cabinet Fasteners

Fastener Type

Nominal

Torque

Torque Range

(in-lbs)

Penta-head security

bolt

100

80-120

3/8” bolt

550

500-600

Hand-hole cover bolt

190

170-210

Table 2: Torque Guidelines for External Bushing

Mounting Hardware

Mounting Type

Nominal

Torque

(in-lbs)

Torque

Range

Low-voltage bushing, mold-

ed Tri-Clamp (without clamp

ring), 3/8” mounting studs

60

40-80

Low-voltage bushing, mold-

ed (with clamp ring), 3/8”

mounting studs

120

90-150

Low-voltage bushing, porce-

lain (with clamp ring), 1/2”

mounting studs

80

70-90

High-voltage bushing, mold-

ed Tri-Clamp (without clamp

ring), 3/8” mounting studs

60

40-80

High-voltage bushing,

molded (with clamp ring),

3/8” mounting studs

120

90-150

High-voltage bushing, por-

celain

80

70-90

When checking tightness of gasketed components, the measured

torque will normally be less than the nominal torque listed in the table

above due to relaxation of the gasket material. Additional tightening of

bushing mounting hardware may cause the component to crack or the

gasket to become over-compressed.

Table 3: Torque Guidelines for External Bushing

Terminal Connections

Terminal Type

Nominal

Torque

(in-lbs)

Torque

Range

High-voltage molded bush-

ing insert

180

170-190

High-voltage porcelain bush-

ing eye-bolt

210

180-240

High-voltage porcelain bush-

ing end cap

168

156-180

Low-voltage bushing, 5/8”

jam nut

600

480-720

Low-voltage bushing, 1” jam

nut

600

480-720

Low-voltage bushing, 1-1/4”

jam nut

720

600-840

Apply silicone grease before installation according to the insert manu-

facturer’s instructions.

When checking tightness of gasketed components, the measured

torque will normally be less than the nominal torque listed in the table

above due to relaxation of the gasket material. Additional tightening of

bushing mounting hardware may cause the component to crack or the

gasket to become over-compressed.