FMI CTS Series User Manual

Page 2

CTS Chemical Treatment System

Supply Voltage: 0-90 VDC**

CTS Supply: 1/4” FNPT CTS Outlet: 1/4” FNPT

IMPORTANT NOTE: Supply and Outlet fittings contain

Buna-N material which is not compatible with fluids

containing chlorine. Do not use the CTS with hypochlorite,

chloramine, or any fluids which contain chlorine

compounds in ANY concentration.

Output Volume: 6.5 GPH max. - CT1(V)

15 GPH max.- CT2(V)

Output Pressure: 125 psi max.

Environment: Humidity: 100% RH non-condensing

Temp: non-freezing to 104°F

Enclosure: Gasketed Fiberglass w/ vent holes.

Dimensions: 15 1/2” x 13 3/8” x 6 3/4”

Weight: 18.6 lbs. (8.4 kg)

** 0-90 VDC supplied by C100A

SPECIFICATIONS

INSTALLATION & SETUP

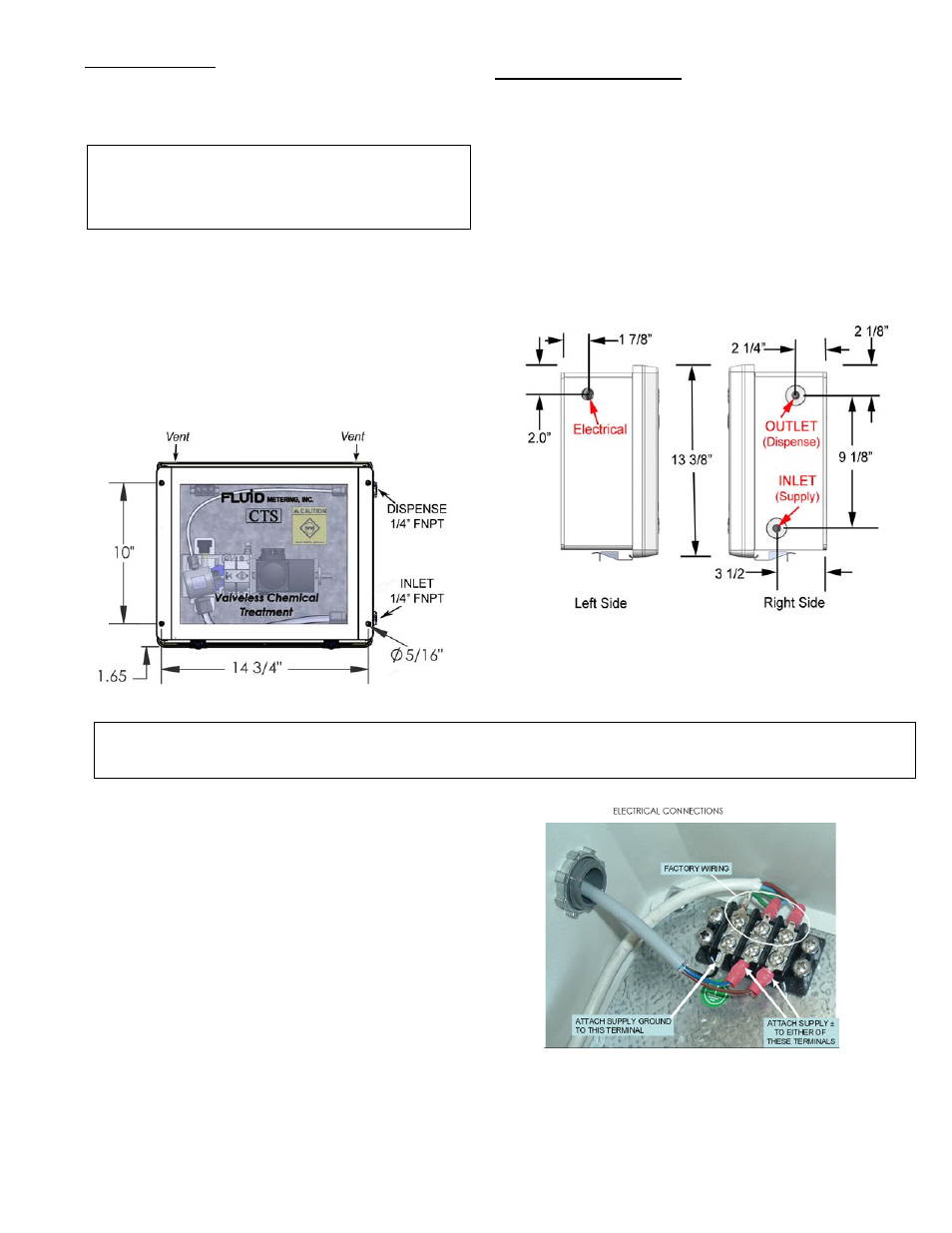

CTS MOUNTING (See diagram page 3)

For optimal performance, mount the CTS as close to

and above the chemical supply reservoir. Securely

fasten the CTS to a wall location with its right side

convenient to the Sodium Hypochlorite supply vessel.

There are 2 mounting holes (5/16” dia) on each side of

the CL enclosure. Utilize all holes for most secure

mounting and mount at least 1 ft. above supply

reservoir.

Diagram 1 (below) shows the mounting hole locations.

ELECTRICAL

On the upper left side of the CTS enclosure is a 7/8”

conduit opening for the electrical supply (0-90 VDC

source from the C100A or customer supplied voltage

controller). Electrical supply wiring should be 3

conductor, minimum 22 AWG. Attach wiring to the

lower 3 spade lugs of the terminal block as shown

below in Diagram 3. Connect the ground wire to the

left most spade lug. Connect the drive wires to the

remaining 2 spade lugs.

It is recommended that electrical connections be

coated with a corrosion protectant such as Aqua-

lube or equivalent.

Note: The CTS is designed so that the motor will

turn in the proper direction, regardless of input

polarity.

Diagram 3

Terminal Wiring

Diagram 1

Mounting Holes

Page 2 of 9

Diagram 2

Electrical & Fluid Connections

IMPORTANT NOTE: There are 2 vent holes located at the top front of the enclosure (under the upper lip of the enclosure cover).

Do not close, seal, or obstruct these vent openings. They are designed to prevent hazardous gases from building up in the

enclosure over time

IN-CTS-13

1/4/13 HW