Duff-Norton SK6405-100 User Manual

Page 7

11. Install hex cap screw (28), washer (30) and Belleville

washers (29) into ID of translating tube (32) (use 3/4 hex

socket with extra long extension).

12. With hex cap screw (28) threads extending out of

translating tube (32)end, apply a generous coat of Exxon

Ronnex Extra Duty #1 grease to thrust washer (30) and

assemble thrust washer (30), Belleville washers (29) on

hex cap screw (28). (See figure 4-1 for proper installation

of washers.)

13. Assemble lock nut (33) on hex cap screw (28), torque

lock nut (33) down to 30 in./lbs.

14. Assemble clevis (35) on hex cap screw (28). Drill 1/8

hole thru clevis end and hex hex cap screw (28) and lock

in place with pin (3 4) (see figure 4-1). Note: Set slip

torque at final assembly for desired slip load.

15. Assemble nut (27) on screw (25). (Flange of nut (27)

towards turned end of screw (25).)

16. Install stop pin (26) into screw (25) taking care to cen-

ter pin.

17. Fill translating tube (32) approximately half full with

Exxon Ronnex Extra Duty #1 grease.

18. Assemble nut (27) into translating tube (32) (align

holes in translating tube with holes in nut). Install pins (31)

(pins should be 1/32 inch above OD of tube). New pins

should be used.

19. Assemble washer (21) on screw (25).

20. Assemble bearing (20) on gear (19) and assemble on

screw (25) and install pin (18) (pin should be centered

when assembled). Take care not to damage gear teeth.

21. Clamp housing (13) in vice (use soft jaws gear cavity

up.) Fill cavity approximately to centerline of pinion (12)

with Exxon Ronnex Extra Duty #1 grease.

22. Assemble translating tube (32), bearing (20) and gear

(19) assembly into housing (13) taking care not to damage

gear (19) teeth. (Rotate pinion (12) while assembling to be

sure of proper mesh of gear (19) teeth and pinion (12)

thread).

23. Grease OD of translating tube (32) with Exxon Ronnex

Extra Duty #1.

24. With translating tube (32) extended approximately 3-

1/2” to 4” from washer (21), assemble outer tube (22) on

translating tube (32) and thread outer tube (22) into hous-

ing (13), against bearing (20) (torque in place at 40 foot

pounds plus or minus 10 foot pounds).

25. Spot drill outer tube (22) thru set screw (17) hole (use

drill slightly smaller than ID of thread). Remove chips and

install set screw (17) and lock in place against outer tube

(22).

26. A. A.C. Unit

I. Align keyway in ball housing (6), and coupling

(5) flats with key in motor adaptor (9) and flats of

pinion (13), assemble motor (3) on motor adaptor

(9) and secure in place with socket head cap

screws (1) and lock washers (2).

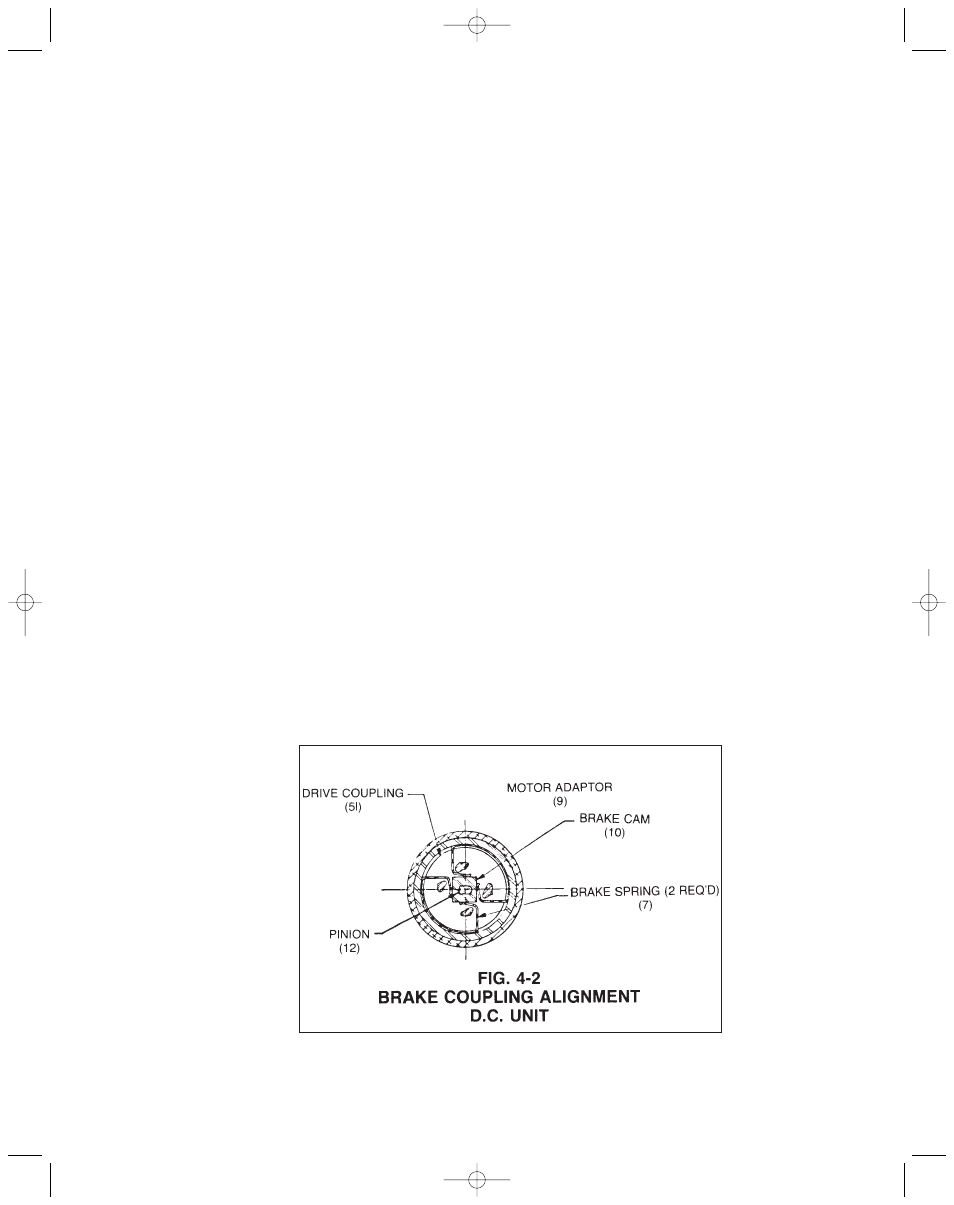

B. D.C. Unit

I. Assemble brake cam (6) on pinion (12).

II. Install brake spring (7) into motor adaptor

(9) (see figure 4-2).

III. Taking care that motor (3) end bells do not

separate from motor (3) shell, align drive cou-

pling (5) pins as shown in figure 4-2 and assem-

ble motor (3) to motor adaptor (9) holding in

place with screws (1).

ASSEMBLY IS COMPLETE.

6405-100 10/10/06 11:50 AM Page 7