5. assembly – Duff-Norton SK6405-100 User Manual

Page 6

translating tube (32).

14. Using 3/16 diameter punch drive pins (313) far

enough into the lifting nut (27) to just clear the translating

tube (32) wall. (Do not drive pins against OD of screw

(25).) Remove nut (27) with screw (25) from translating

tube (32).

15. Remove screw (25) from nut (27).

16. Remove pins (31) from nut (27) by driving pins (31)

remaining distance into ID of nut (27).

17. Remove stop pin (26) from screw (23).

18. Drive pin (34) from clevis end (35).

19. While restraining hex cap screw (28) from rotating,

remove clevis (35) from cap screw (28). (Cap screw can

be restrained from turning by using a 3/4 hex socket with

long extension into translating tube (32) ID.)

20. Remove lock nut (33) from cap screw (28).

21. Remove Belleville spring washers (30) and thrust

washer (29).

22. Remove cap screw (28), Belleville washers (30) and

thrust washer (29) from ID of translating tube (32).

23. Drive pin (4) from motor (3) shaft and remove coupling

(5) and remove damper (36) from I.D. of coupling. Note if

coupling is not damaged, it need not be removed.

24. A.C. unit - ball brake disassembly. Remove set

screws (7c) from ball housing (6) and remove springs (7b)

and balls (7a) and remove drive coupling (5) from ball

housing (6).

25. If bushing (16) in housing (13) is worn remove.

26. If bushing (14) in housing (13) clevis is worn, press

bushing (14) out.

27. If bushing (15) in housing (13) is worn, press bushing

out.

DISASSEMBLY IS COMPLETE.

4-5. Assembly:

1. A. Install damper (36) into coupling (5) I.D. and assem-

ble drive coupling (5) with hole in motor (3) shaft and

install pin (4).

B. A.C. Unit Only

I. Assemble ball housing (6) on drive coupling (5)

(line up ball cavities with groove in

coupling, assemble balls (7a), spring (7b) into

ball cavity and thread set screw (7c) into ball

housing (6), adjust set screws (7c) until torque

required to turn motor (3) shaft and coupling

(5) is 22 oz./in to 28 oz./in., while restraining ball

housing (6) from rotating. (note set screw (7c)

will be approximately flush with OD of ball hous-

ing (6).)

2. Assemble bearing (11) on pinion (12) and install retain-

ing ring (10) on pinion (12).

3. Apply Loctite retaining compound (or equal) to OD of

bushing (15) and install in housing (13) (assemble into

housing (13) end opposite side of housing with (4) holes

for mounting motor adaptor (9).

4. Press bushing (14) in housing (13) clevis.

5. Press bushing (16) in housing (13).

6. Install pinion (12) bearing (11), retaining ring (10) into

housing (13).

7. Assemble motor adaptor (9) onto housing (13) holding

in place with screws (8).

8. Press bushing (23) into outer tube (22).

9. Install seal (24) in outer tube (22) (seal scraper should

be facing inward).

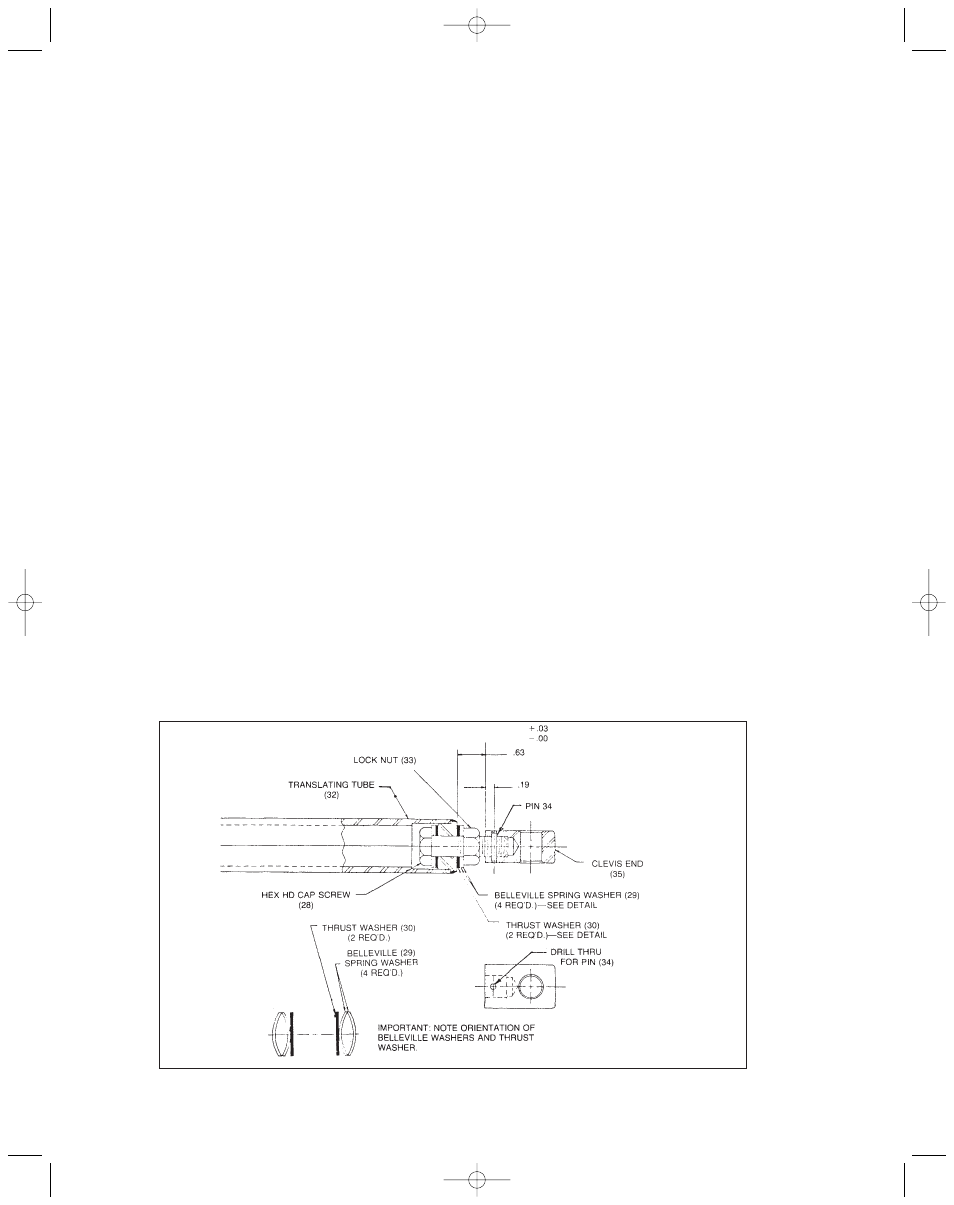

10. Apply a generous coat of Shell Darina EP2 grease to

thrust washer (30) and assemble thrust washer (30) and

Belleville washers (29) on hex cap screw (28) (see figure

4-1 for proper installation of washer).

FIGURE 2-1

SLIP CLUTCH ASSEMBLY

6405-100 10/10/06 11:50 AM Page 6