Duff-Norton EM1010-100 (TMD02) User Manual

Page 5

INSTALLATION

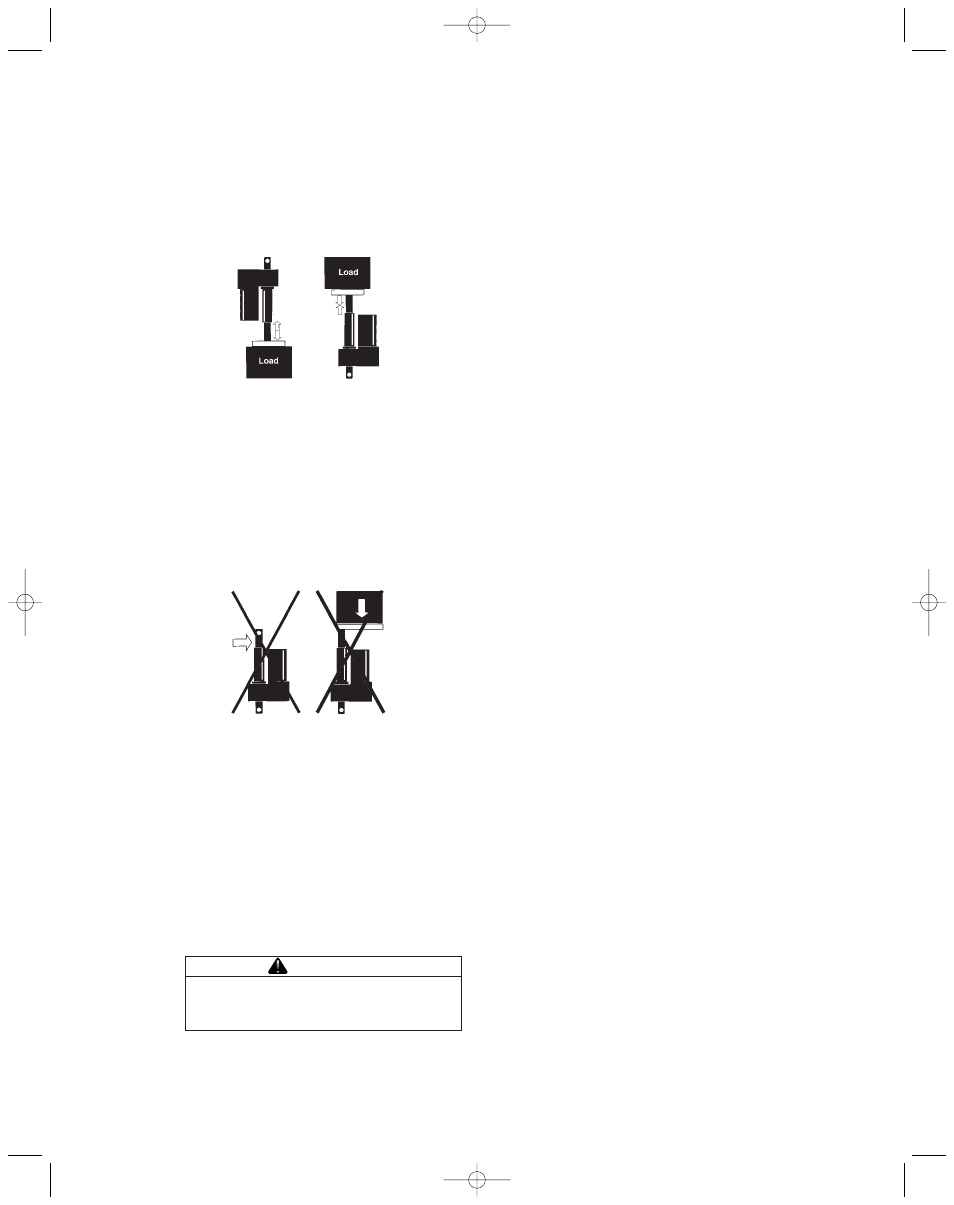

2-1 Direction of Loading

Duff-Norton electromechanical actuators

can be used in tension, compression, or

combination tension/compression applica-

tions. Examples are as shown below.

It is important to mount the actuator so that

side loading or eccentric loading are avoid-

ed. To optimize the ----- performance and

life of the actuator, it should be mounted so

that the load is applied along the longitudi-

nal axis of the translating tube, with freely

pivoting clevis attachments. Examples of

improper loading are shown below.

2-1 Limit Switches

These actuators do not have clutches or

other provision for accommodating end of

stroke jamming. Thus, electrical limit

switches must be provided. Actuators are

available from the factory with or without

magnetically activated limit switches are not

utilized, external limit switches must be pro-

vided by the installer.

2-1 Wiring Connections

Actuators with factory installed Limit Switches

1. Either 12 or 24 volts DC, to match the voltage rat-

ing of the actuator, should be connected to the two

terminals of the relay board which do not have other

connections (see wiring diagram). Reverse DC polar-

ity to reverse actuator.

2. Actuator speed control by operation on reduced

voltage should not be used, as this will prevent prop-

er operation of the control relay.

Actuators with limit switches by installer

1. Power supply to the actuator should be protected

by a fuse with standard blow characteristics. Proper

fuse sizing is 8 amps for 12 volt units and 5 amps for

24 volt units.

2. Power from the control circuit, which should

include limit switches and appropriate controls,

should be connected directly to motor terminals.

2-4 Limit Switch Adjustment

Actuators with factory installed switches are shipped

with switches adjusted for maximum retraction and

travel. Attempting to increase stroke in either direc-

tion invites actuator jamming which will result in

irreparable damage. Stroke may be reduced on

either end of travel by loosening screws attaching

switches, sliding along tube, and resecuring.

OPERATION

3-1 Operating Conditions

The actuator should be operated within its ratings for

load, duty, and temperature (see 1-3. Specifications).

Rapid jogging or plug-reversals should be avoided.

Stalling the actuator by overloading or by improper

limit switch setting will result in rapid failure.

INSPECTION AND MAINTENANCE

4-1 Safety Note

Disconnect power from actuator before making

repairs.

4-2 Inspection

Inspect periodically for loose or damaged parts,

including clevis attachment pins.

4-3 Maintenance

No periodic maintenance is required or prescribed.

Replacement parts are not available.

4-4 Lubrication

The actuator is lubricated at the factory.

Relubrication is not generally required.

IMPROPER SIDE LOADING

PROPER LOADING

Tension

Compression

CAUTION

Be sure power connections are not live

before connecting to actuator.

EM-1010-100_0706 7/31/07 2:40 PM Page 4