Commissioning, Maintenance and cleaning, Appendix 1: declaration of conformity – WIKA 111.11 User Manual

Page 3

Permissible vibration load at the installation site

■

The instruments should always be installed in locations free from vibration.

■

If necessary, it is possible to isolate the instrument from the mounting point by installing

a flexible connection line between the measuring point and the pressure gauge and

mounting the instrument on a suitable bracket.

■

If this is not possible, the following limit values must not be exceeded:

Dry gauges:

Frequency range < 150 Hz

(Model 111)

Acceleration < 0.7 g (7 m/s

2

)

Liquid-filled gauges: Frequency range < 150 Hz

(Model 113, 213)

Acceleration < 4 g (40 m/s

2

)

The liquid filling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

4. Commissioning

During the commissioning process pressure surges must be avoided at all costs. Open the

shut-off valves slowly.

5. Maintenance and cleaning

■

The instruments are maintenance-free.

■

The indicator should be checked once or twice every year. For this the instrument must

be disconnected from the process to check with a pressure testing device.

■

Clean the pressure gauge with a moist cloth.

■

Repairs must only be carried out by the manufacturer or appropriately qualified skilled

personnel.

■

When dismounting, close the compensating valve (if available).

WARNING!

Residual media in dismounted pressure gauges can result in a risk to persons,

the environment and equipment.

Take sufficient precautionary measures.

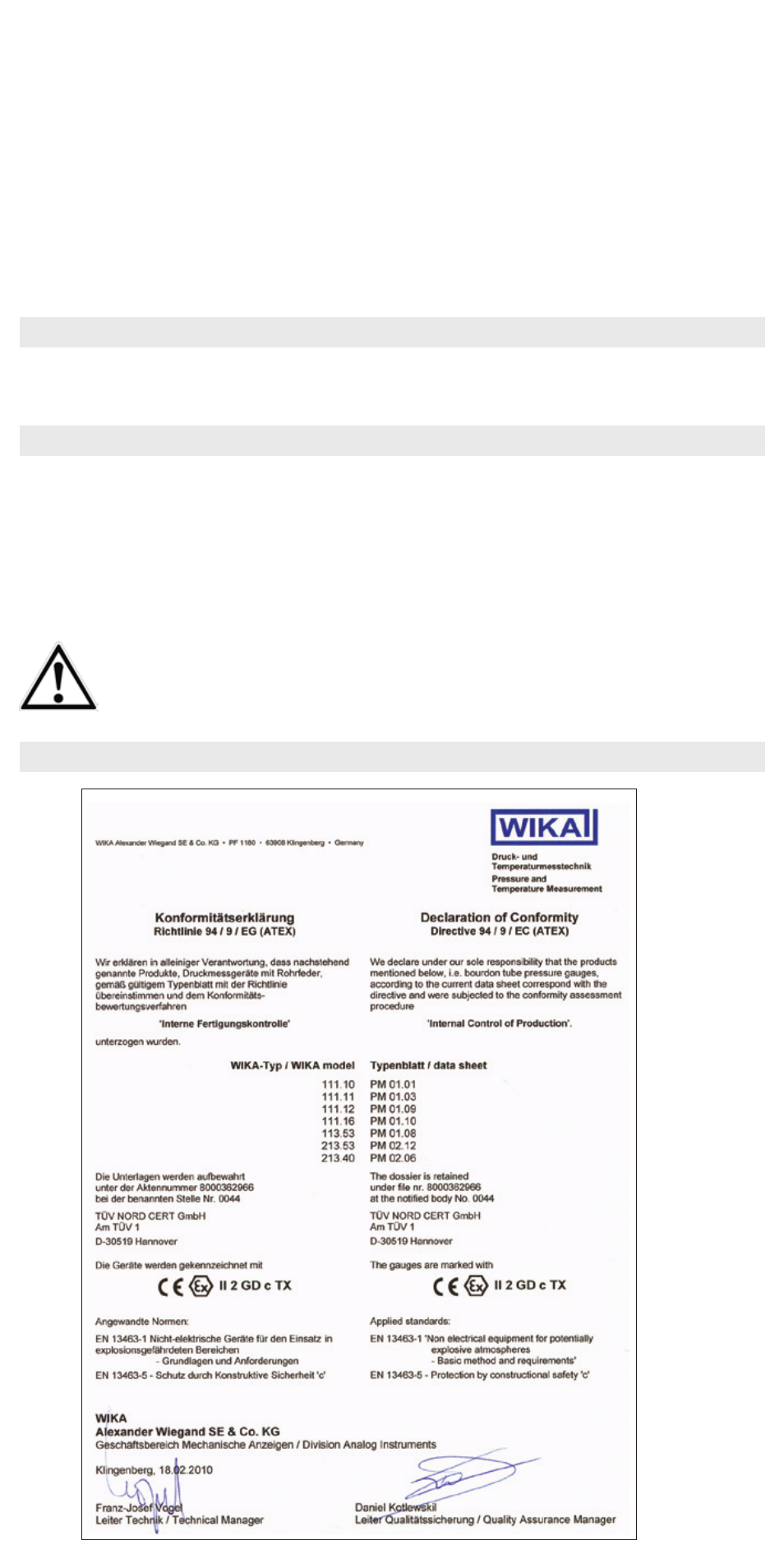

Appendix 1: Declaration of conformity