Instruction manual ni-281e – WIKA PCA_HP User Manual

Page 3

INSTRUCTION MANUAL

NI-281E

Rev. 5 11/02

5.1 PRELIMINARY OPERATIONS

CAUTION: do not open the cover of explosionproof pressure

switches (Series PCA) when energized, in explosive

atmospheres.

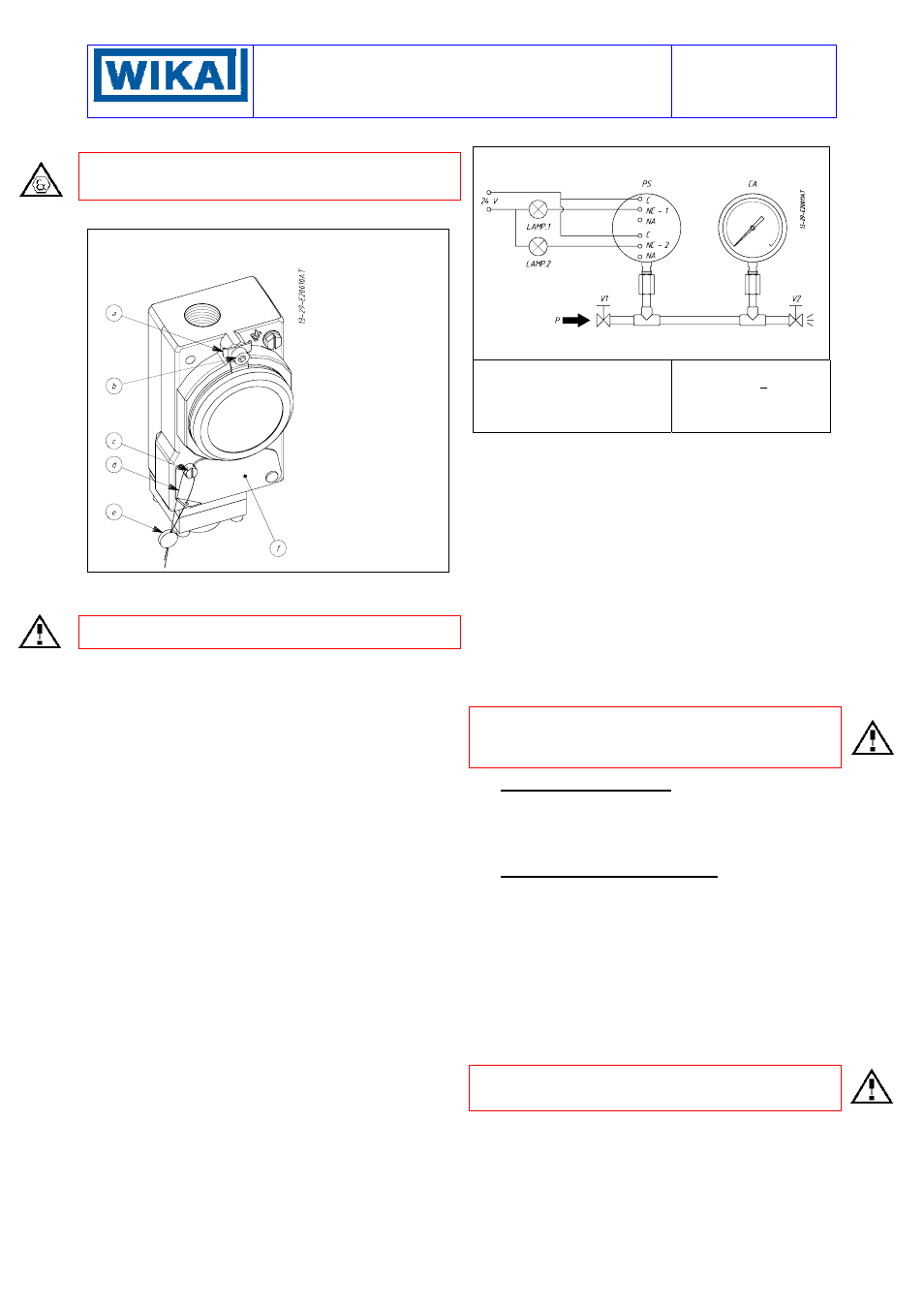

With reference to Fig. 3 unscrew the screw (b) until the blocking

device (a) can be turned 180°; then unscrew the cover.

Fig. 3 -

Weatherproof pressure switch cover blocking

device and plumbing

a. Cover blocking

device

b. Blocking screw

c. Screw blocking

the adjustment

bush access

plate

d. Flexible steel

wire

e. Plumbing

f. Adjustment

bush access

plate

CALIBRATION CIRCUIT AND The warning lamps should be

connected to the contacts in the NA or NO position according to

the required contact action.

If the instrument is equipped with two microswitches, take into

account that they actuate simultaneously within rated tolerances.

The warning lamps can either be connected by means of a

thimble with a maximum diameter of 2.5 mm or by means of a test

plug with a diameter of 2 mm to be inserted in the appropriate

holes situated frontally beside the terminal screw (see Fig. 2).

Connection of C and NA terminals

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure increases when the desired values is

reached (MAX. closing).

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure decreases when the desired value is

reached (MIN. opening).

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure increases when the desired value is

reached (MAX. opening).

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure decreases when the desired value is

reached (MIN. closing).

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure switch

range and should have an accuracy consistent with the precision

required to calibrate the set point.

The pressure switch must be mounted in the normal installation

position, i.e. with the pressure connection downwards.

Avoid forcing the microswitch by hand or with tools. This could

affect the instrument functioning.

With reference to Fig.3, free the access to the adjustment bush by

loosening the screw (c) which holds the closure plate (f).

Increase the pressure in the circuit up to the desired microswitch

set point value.

Turn the adjustment bush using the adjustment rod with which the

instrument is equipped (Fig. 2) until the relative lamp turns on (or

turns off); then turn it in the opposite direction until the lamp turns

off (or on). Slowly turn the bush again until the lamp turns on (or

off).

Fig. 4 -

Calibration circuit

PS - Pressure switch

CA - Test gauge

V1 - Inlet valve

V2 - Discharge vale

P - Pressure source

Test fluid:

air for

P < 10 bar

water for

P > 10 bar

Check the calibration value (varying the pressure in the circuit

accordingly) and register it, using a pen with indelible ink, on the

ratings.

5.2 CALIBRATION USING REGULATION SCALE

See the specific instructions attached with instruments with this

option.

5.3 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.

With reference to Fig. 2, insert the adjustment rod into the

appropriate seat; close the access to the adjustment bush by

rotating the closure plate (4) and tighten the relative screw (6).

Take the cover, ensure that the sealing gasket is correctly fitted

into its seat, insert the cover onto the case and turn it clockwise

until the cover is closed.

With reference to Fig. 3 turn the blocking device (a) 180° sliding

the tongue into the appropriate seat in the cover; tighten the

blocking screws (b).

Mount on pressure connectionn and cable entry the protection

caps supplied with the instrument.

CAUTION: the protection caps should only be definitively

removed during the connection steps (see § 7).

6 - INSTRUMENT PLUMBING

The plumbing, aimed as a guarantee against possible tampering

of the calibrations, can be carried our using a flexible steel wire

(d) inserted into the holes in the screw (c) and the adjustment

bush closure plate provided for this purpose (see Fig. 3).

7 - MOUNTING AND CONNECTIONS

7.1 MOUNTING

Surface mount the instrument by mean of the holes, or pipe

mount using the appropriate bracket (see Fig. 8) or mount directly

on the plant in a vertical position (with the pressure connection

downwards). The chosen position must be such that the

possibility of shocks or temperature changes are within tolerable

limits. The above also applies to direct mounting. With gas or

vapour process fluid, the instrument must be positioned higher

than the pipe inlet (see Fig. 7). With a liquid process fluid, the

instrument can be positioned higher or lower, indifferently (see

Fig. 6 and 7). In this case, during set point calibration the

negative or positive head must be taken into account.

CAUTION: positions other than vertical are allowed provided

environmental conditions do not cause condensation to form or

water to enter the instrument through the ventilation path.

7.2 PRESSURE CONNECTIONS

For a correct installation it is necessary to:

Mount a shut-off valve with drain (root valve) on the process tube

to allow the instrument to be excluded and the connection tubing

to be drained. It is recommended that said valve has a capstan-

blocking device aimed at preventing it being activated casually

and without authorisation.

Mount a service valve near the instrument to permit possible

functional verification on site. It is recommended that the service