Exterior installation (cont’d) – M&G DuraVent DuraTech® Canada User Manual

Page 11

11

EXTERIOR INSTALLATION (CONT’D)

Attach the flue extension to the horizontal chimney length using the three

metal screws provided.

Stack a chimney length on top of the tee. Turn it clockwise to lock it in place.

FOR UNENCLOSED INSTALLATION OR VENTING OF OIL

OR GAS APPLIANCES:

Continue until the required chimney height is reached.

NOTE: At 8' intervals, attach the chimney to the wall using a wall band

(DTC-WSU).

If the chimney passes through the roof, cut a hole large enough to

provide 2" clearance between the chimney and the roof. For pitch roof,

see table 3 on page 3.

FOR ENCLOSED INSTALLATION AT 2" FROM COMBUSTIBLES

(Woodstove or coal burning appliance only):

Put a first chimney length on the Tee. Turn it clockwise to lock it in place

(see figure 4).

Note: the male coupling must be on top.

Slide a Radiation Shield Connector on that first chimney section and

fasten it using 3 self tapping metal screws.

Stack the next chimney length on the first length. Be sure that the male

and female threads are not in line when putting the lengths together. Turn

the chimney clockwise to lock it in place. You may add a 1/2in stainless

steel self tapping screw to prevent accidental unlocking.

Slide a telescopic rigid shield over that section and attach it to the radiation

shield connector.

Continue installing chimney sections up through the roof opening. Pull

the telescopic shield tube up to the roof opening Adjust the length of the

shield tube so that it terminates just above the roof opening but under the

flashing. Screw the sections of the shield together using 3 self tapping

screws per joint.

TO CONTINUE, SEE ROOF FLASHING INSTALLATION, ON PAGE 5.

Attach the clean-out cap to the support's flue extension using the

three metal screws provided. Make sure that the screws have pierced

through the flue extension. The cap is in the box with the insulated tee. If

an insulated tee cap is used, twist lock the tee cap to the tee (adjustable

support DTC-TSA only).

The minimum length of insulated chimney required to pass through the

wall will be thickness plus 7". The insulated chimney must extend at least

5" into the room beyond the finished wall. Insert this chimney length in

the side entry of the insulated tee. Turn it clockwise to lock it in place.

Seal this joint by wrapping it with the aluminium tape supplied with the

tee.Mount the insulated tee on the support so that the chimney length

which will go through the wall is perpendicular to the side of the support

that will fasten to the wall.

This step will require 2 people: (See figure 20)

Insert the chimney length of this tee-support assembly into the hole in

the wall. Using a level, ensure the tee is vertical, then attach the support

to the wall using (8) Nº. 10 x 1 - 1/4" wood screws or 4" spiral nails.

NOTE: To provide sufficient strength, the nails must be driven into the

wall studs. For concrete walls, the support should be attached using (8)

1/4" x 2" lag bolts.

4

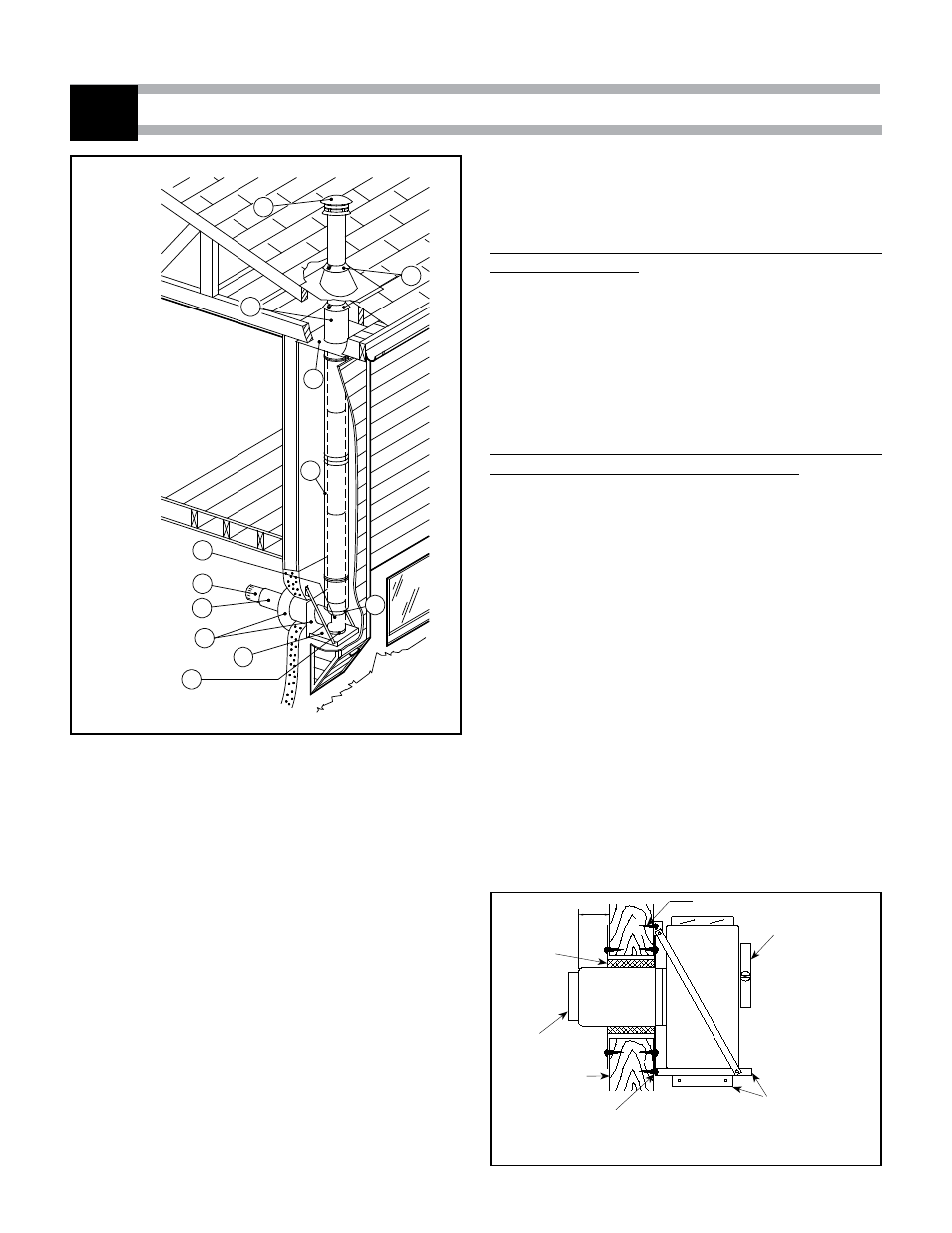

Figure 19

1. CAP

2. WALL THIMBLE

3. INSULATED TEE

4. INSULATED LENGTH

5. TEE SUPPORT

6. FLUE EXTENSION

7. PREMIUM SHIELD

8. RADIATION SHIELD FIRESTOP

9. RADIATION SHIELD CONNECTOR

10. STORM COLLAR

11. RAIN CAP

12. CENTERING SPRING

9

3

6

4

2

5

1

7

8

10

11

12

Figure 20

5" Min.

WALL THIMBLE

(DTC-WTI)

WALL STUD

FLUE EXTENSION

(DTC-AD)

4 in. Nails or #10 x 1-1/4 in. Screws

LEVEL

4 in. Nails or

#10 x 1-1/4 in. Screws

INSULATED

CHIMNEY

(DTC-_SS)

TEE SUPPORT OR ADJUSTABLE TEE SUPPORT

(DTC-TS OR DTC-TSAC) AND INSULATED TEE CAP

(DTC-TCSS) OR ADJUSTABLE WALL SUPPORT

(DTC-TSA) AND INSULATED TWIST-LOCK CAP

(DTC-TCI) OR DRAIN TEE CAP (DTC-TCD)