Important trouble shooting tips – HES 8500 User Manual

Page 3

Important Trouble Shooting Tips

NOTE: In order to ensure proper catch and release of the latchbolt,

the 8500 electric strike requires that the opening be plumb and square .

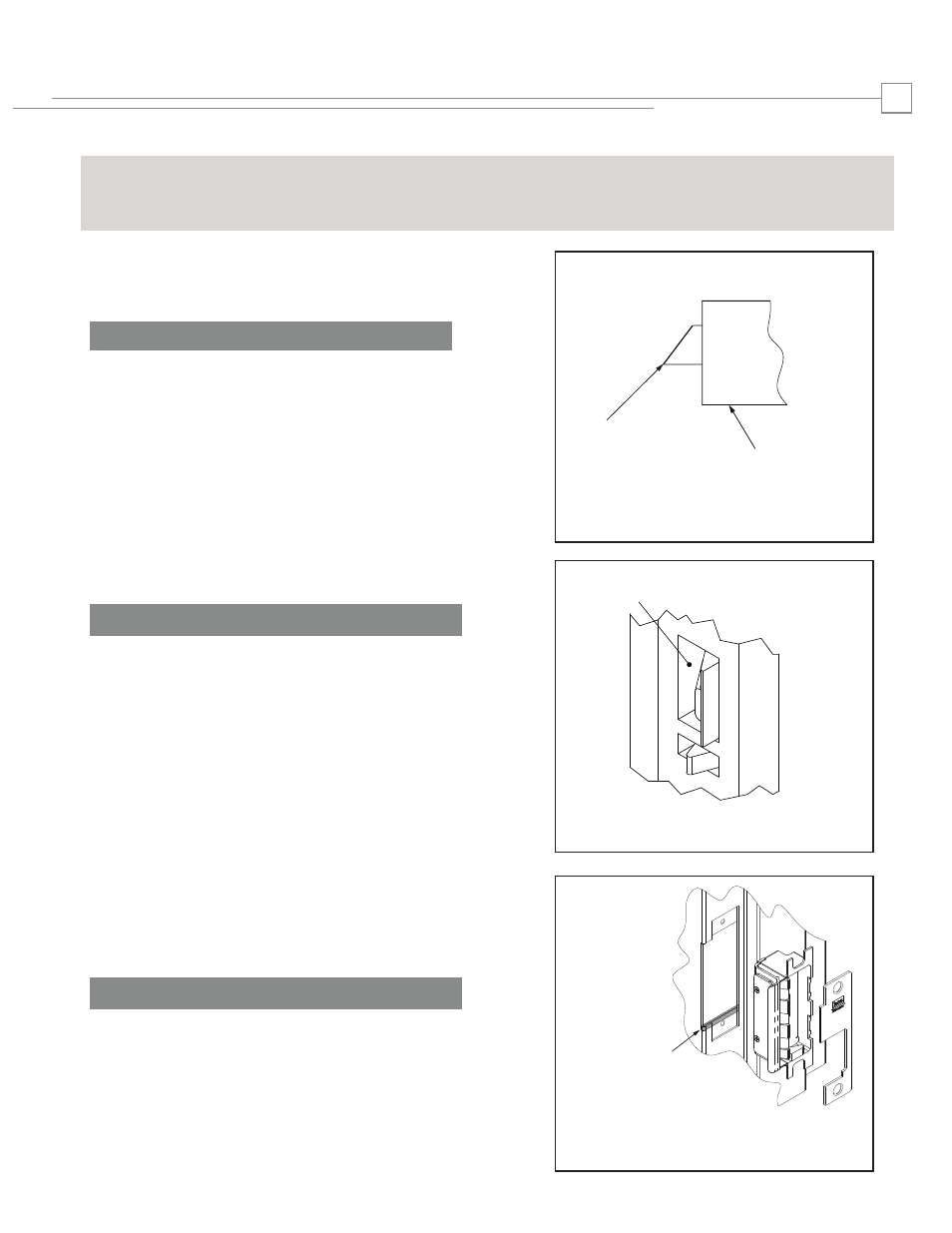

EVALUATING LATCH BOLT CONDITION

ACCOMMODATING DOOR SAG

DOOR FACE

APPLY FORCE IN

THIS DIRECTION

TO LATCH BOLT

APPLY LUBRICANT TO THIS SURFACE

Figure 2: Lubricate latch bolt as required

If latch bolt does not

clear faceplate, remove

material as shown

and install SD faceplate

Figure 3: Door Sag Adjustment

Door sag and latchbolt wear are two common conditions that

may prevent an electric strike from working properly. Here are

some quick tips to ensure the HES 8500 performs at its best:

Poorly constructed, worn or damaged latchbolts may not

interact properly with the ramp of an electric strike.

Check the condition of your latchbolt by lightly pressing the tip

of the latchbolt at a 45 degree angle to the door face. (See Figure 1).

The latchbolt should be pushed easily into the door.

If abnormal resistance is encountered, apply a lubricant to the

inside of the latchbolt opening while pressing the latchbolt .

(See Figure 2). If this does not correct the friction,

additional maintenance on the latchbolt may be required.

Note: Check with the latchbolt manufacturer regarding

proper latchbolt maintenance and approved lubricants.

Most doors experience some sagging over time. To check for

door sag, look at the location of the lock’s deadlatch in relation

to the 8500’s deadlatch platform. The deadlatch should rest

on the deadlatch platform. If the deadlatch contacts the faceplate

or the edge of the 8500’s body, the latchbolt may not be fully

released when the strike is activated causing the door not to be

released.

To correct this condition, remove the 8500 and cut material

from the bottom edge of the frame opening and possibly the

mounting tabs (Note: make sure to sure to retain the mounting

hole). This allows the 8500 to be shifted down slightly in the frame.

Reinstall the 8500, using the SD faceplate instead of the standard

faceplate.

If this does not correct the issue, additional maintenance on the

door may be necessary.

Lubrication of the 8500 electric strike is not necessary.

Figure 1: Apply force to latch bolt

3

STRIKE LUBRICATION