Troubleshooting guide – Graymills 795-90716 LKN User Manual

Page 14

Graymills Corporation – 3705 N. Lincoln Avenue – Chicago, IL 60613 – 773-248-6825 – Fax 773-477-8673 –

www.graymills.com

– 14

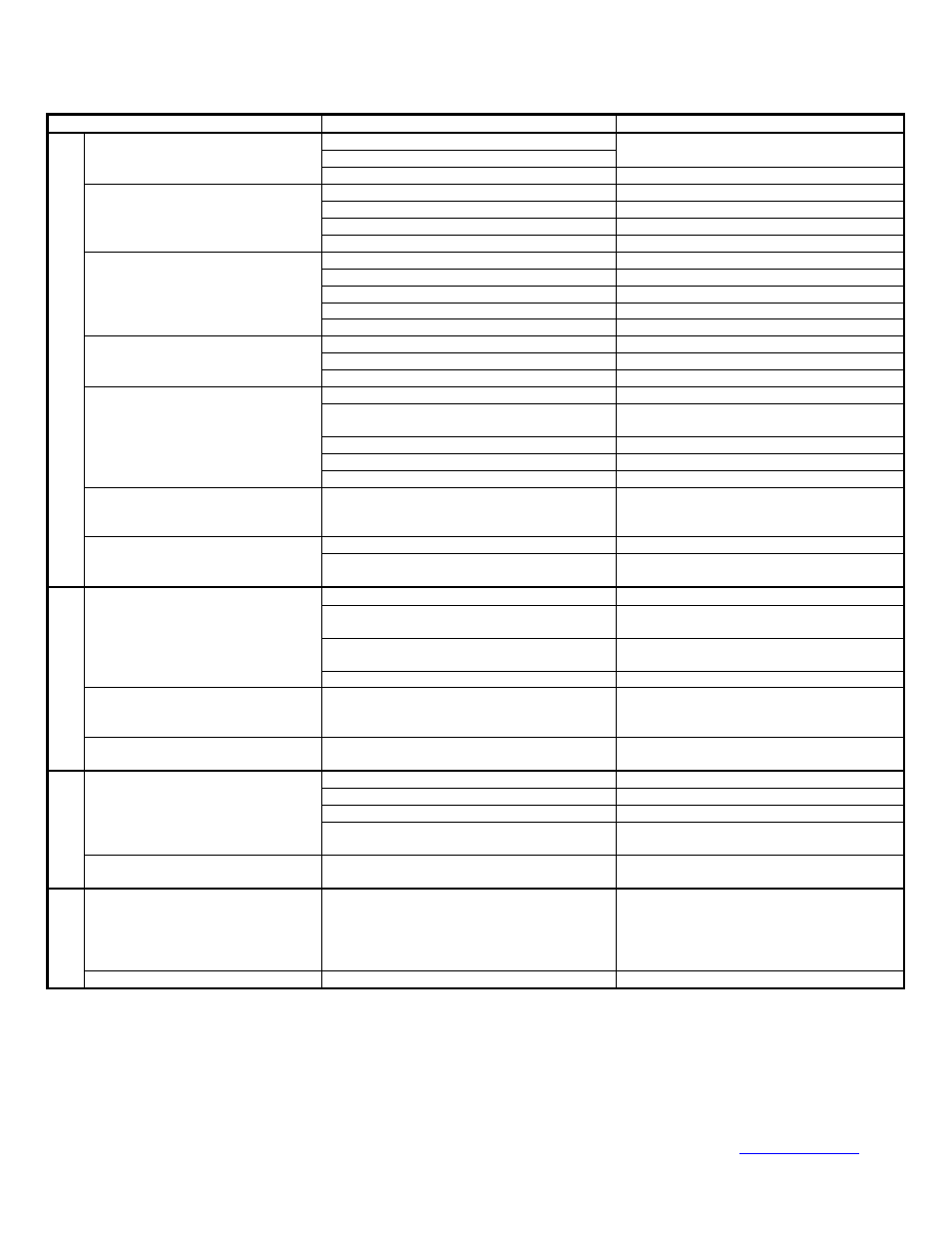

TROUBLESHOOTING GUIDE

CONDITION POSSIBLE

CAUSE

CORRECTION

Platform not at top of stroke

Machine not “READY”

Press RESET button

“READY” light not illuminated

Position sensor malfunctioning

Check/replace sensor

Low air supply

Adjust FRL to read 90-100 PSI

Items left on lid causing obstruction

Remove obstruction

Position sensor malfunction

Check/replace sensor

”LID LIFT FAILED” Screen

Malfunctioning solenoid valve

Check/replace valve

Low air supply

Adjust FRL to read 90-100 PSI

Items on platform causing obstruction

Remove obstruction

Position sensor malfunction

Check/replace sensor

Machine overloaded

Remove load

“LIFT PLATFORM FAILED TO

RAISE” Screen

Malfunctioning solenoid valve

Check/replace valve

Obstruction beneath platform

Remove obstruction

Position sensor malfunction

Check/replace sensor

“LIFT PLATFORM FAILED TO

DESCEND COMPLETELY” Screen

Malfunctioning solenoid valve

Check/replace valve

Post Emergency Stop reset

Press RESET again

No air pressure

Ensure air pressure supplied to machine,

check air line to safety link for leaks

Safety link valve malfunction

Inspect/replace safety link valve

Safety link failed due to fire

Contact Graymills

“SAFETY LINK ACTIVATED”

Screen (Heated units only)

Safety link failed due to malfunction

Inspect/replace safety link

Touchscreen not powering up after

disconnect actuated

Circuit breakers in control enclosure tripped

Power off machine, open enclosure, reset

breakers if tripped. If problems persist,

contact Graymills

Touchscreen screen saver is on

Touch screen to enable

PLC Control

Touchscreen dark while machine

cycling

Touchscreen failure

Check connections and replace if

necessary

Electrical service to motor is incorrect

Check electrical supply and correct

Motor is burned out

Replace motor or return pump to Graymills

for repair

Motor breaker tripped

Check breakers and correct. If problems

persist, contact Graymills

Pump does not run

Faulty motor contactor

Check/replace

Pump runs but does not agitate

Pump rotation is incorrect (3-phase power

only)

Swap connections of two of the three

electrical leads to the motor (CCW is

correct rotartion)

Optio

n

al Pum

p

Pump runs, but is noisy (Some

noise is normal)

Cavitation due to low liquid level

Raise liquid level to correct level

Thermostat set too low

Raise thermostat setting

Faulty heater(s)

Check/replace

Malfunctioning heater contactor(s)

Check/replace

Tank does not reach proper

operating temperature

24/7 settings incorrect

Check timer settings to ensure they are

correct

Op

tion

al Heat

Tank takes too long to heat

One element of tri-element heater(s) is

burned out

Check/replace

Up/down motion of lift platform is

noisy

Roller wheels wearing and may need

replacing

Visually inspect wheels for wear. Graymills

recommends replacing all wheels at once

to minimize risk of future failures and

downtime. Contact Graymills for more

information.

Other

Skimmer (optional) not turning on

Bad motor

Check/replace