Lkn dimensions and specifications, Lock-out procedures, Lubrication – Graymills 795-90716 LKN User Manual

Page 13: Pneumatic system, Lock-out procedures lubrication pneumatic system, Maintenance

Graymills Corporation – 3705 N. Lincoln Avenue – Chicago, IL 60613 – 773-248-6825 – Fax 773-477-8673 –

www.graymills.com

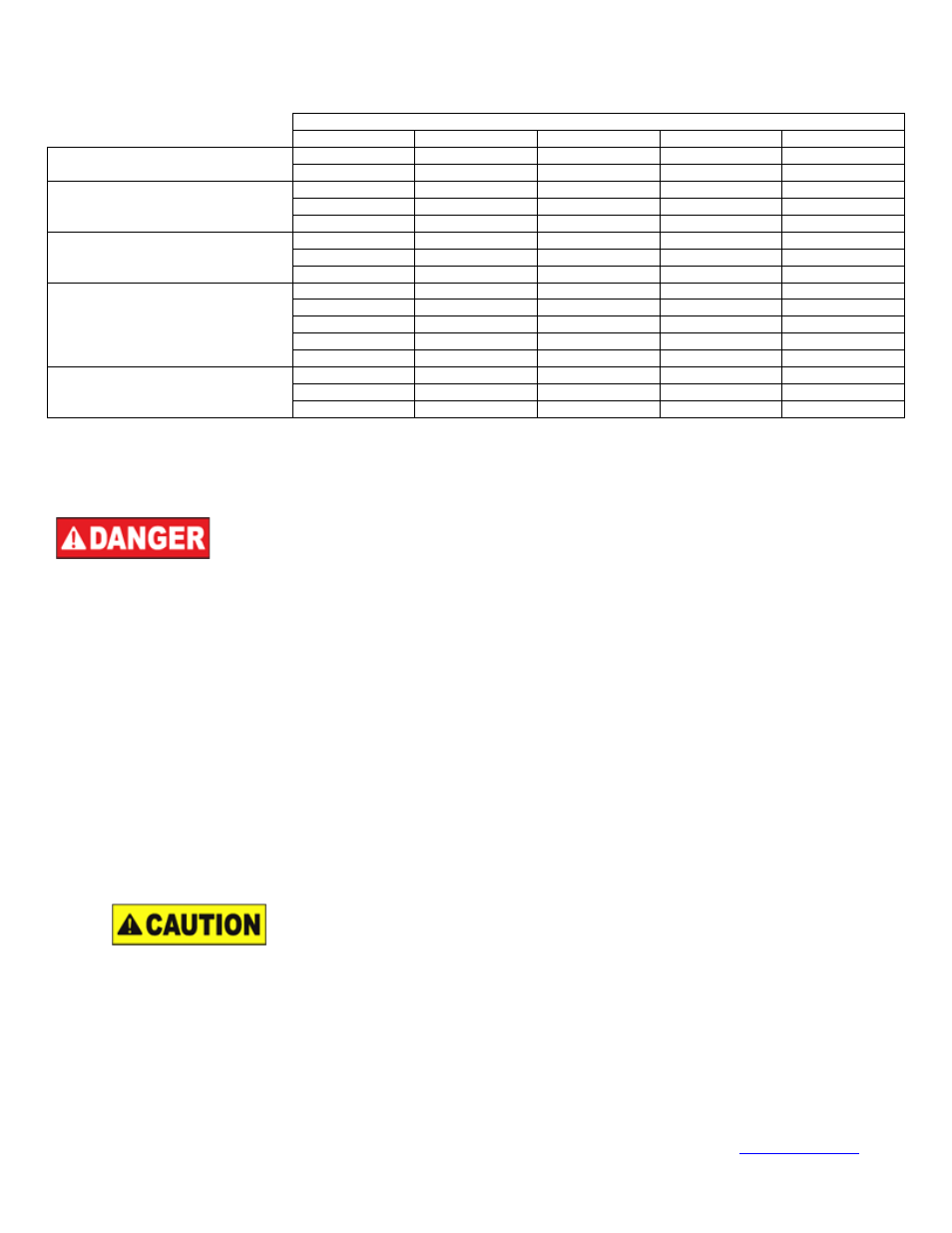

LKN DIMENSIONS AND SPECIFICATIONS*

Standard Models**

Series LKN36

Series LKN48

Series LKN60

Series LKDN60

Series LKDN72

Standard

550 lbs.

450 lbs.

700 lbs.

700 lbs.

700 lbs.

Maximum

Load Capacity

Heavy-Duty***

980 lbs.

880 lbs.

1,850 lbs.

1,850 lbs

1,750 lbs.

Left to Right (W)

54 ½”

66 ½”

78 ½”

78 ½”

90 ½”

Front to Back (L)

45” 57” 57” 57” 63”

Overall

Machine

Height

76” 76” 76” 96” 96”

Left to Right (W)

42 ½”

54 ½”

66 ½”

66 ½”

78 ½”

Front to Back (L)

45” 57” 57” 57” 63”

Tank Outside

Top to Floor

51” 41” 41” 51” 51”

Left to Right (W)

40” 52” 64” 64” 76”

Front to Back (L)

34 ½”

46 ½”

46 ½”

46 ½”

52 ½”

Total Depth

35” 35” 35” 45” 45”

Liquid Depth

27” 27” 27” 37” 37”

Tank Inside

Volume

170 Gallons

290 Gallons

355 Gallons

491 Gallons

667 Gallons

Left to Right (W)

36” 48” 60” 60” 72”

Lift Platform

Front to Back (L)

24” 36” 36” 36” 42”

Maximum Part Height

20” 20” 20” 30” 30”

*

Dimensions and specifications are approximate and are subject to change

**

Custom units available. Contact Graymills for more information

***

Greater capacity units available. Contact Graymills for more information

MAINTENANCE

Follow all Lock Out procedures before performing any service or maintenance.

Lock-Out Procedures

•

When performing any maintenance tasks on the Liftkleen be sure that the master on/off air line valve is in the “Off” position.

•

Disconnect the main air supply to the rack and/or lid cylinders to remove residual air pressure.

•

Turn electric power to machine “Off” at main disconnect.

Lubrication

•

Lubricate the lift channels or roller track with machinery grade grease. It is recommended that this lubrication be done at least

every month.

•

Lubricate the lid hinges by oiling with light machinery oil (SAE 30W or equivalent). This should be done every month. This

includes the lid hinges and the lid opening mechanism. Entire lid mechanism should be inspected for wear, especially hinges

and bolt attaching lift to cover.

Pneumatic System

•

The FRL unit on the side of LKN must be checked at least weekly. The moisture in the filter bowl is drained by opening the

drain valve at the bottom of the unit. This is especially important during hot weather and may require more frequent attention.

•

The lubricator must be filled as required with SAE 10W oil or its equivalent and set approximately at 3 drops per minute. The

pressure regulator is adjustable between 60-110 PSI. Remember, the unit’s lifting capacity changes as the air pressure goes

up and down. Recommended pressure is 90 - 100 PSI.

•

DO NOT USE SYNTHETIC OIL in the machine’s FRL. Synthetic oil may cause the buna o-rings in the machine’s air

valves to swell and fail!

– 13