Troubleshooting guide – Graymills MVP Series Pump OMI User Manual

Page 4

- 4 -

bolts, two on each side, from the coupling. The

shaft pin should then be accessible and the shaft

can be removed from the pump.

The seal face is pressed into the pump housing.

Inspect for damage. If necessary replace by prying

out with a screwdriver. Inspect O-Ring that

surrounds seal face. Replace O-Ring if damaged.

Replace seal face by pressing in a new face in the

housing.

Reassembly

With new seal face installed in housing, replace shaft

and pin and secure coupling with four Allen-head bolts.

Replace coupling guard and screws.

Replace mechanical seal on shaft. Replace circlip

on shaft below seal.

Reinstall stages in the reverse order of removal.

Stages should not be warped, bent or damaged.

Note carefully how spacers are used to prevent

impeller from contacting the bowl/diffuser. Replace

nut and lock washer on shaft to retain stages.

Replace O-Ring in pump housing and fit

intermediate chamber sleeve into pump housing.

Install stay bolts into motor casing. Place O-Ring

into suction cover and place suction cover over

intermediate chamber cover. Thread nuts onto end

of stay bolts and tighten to retain suction cover.

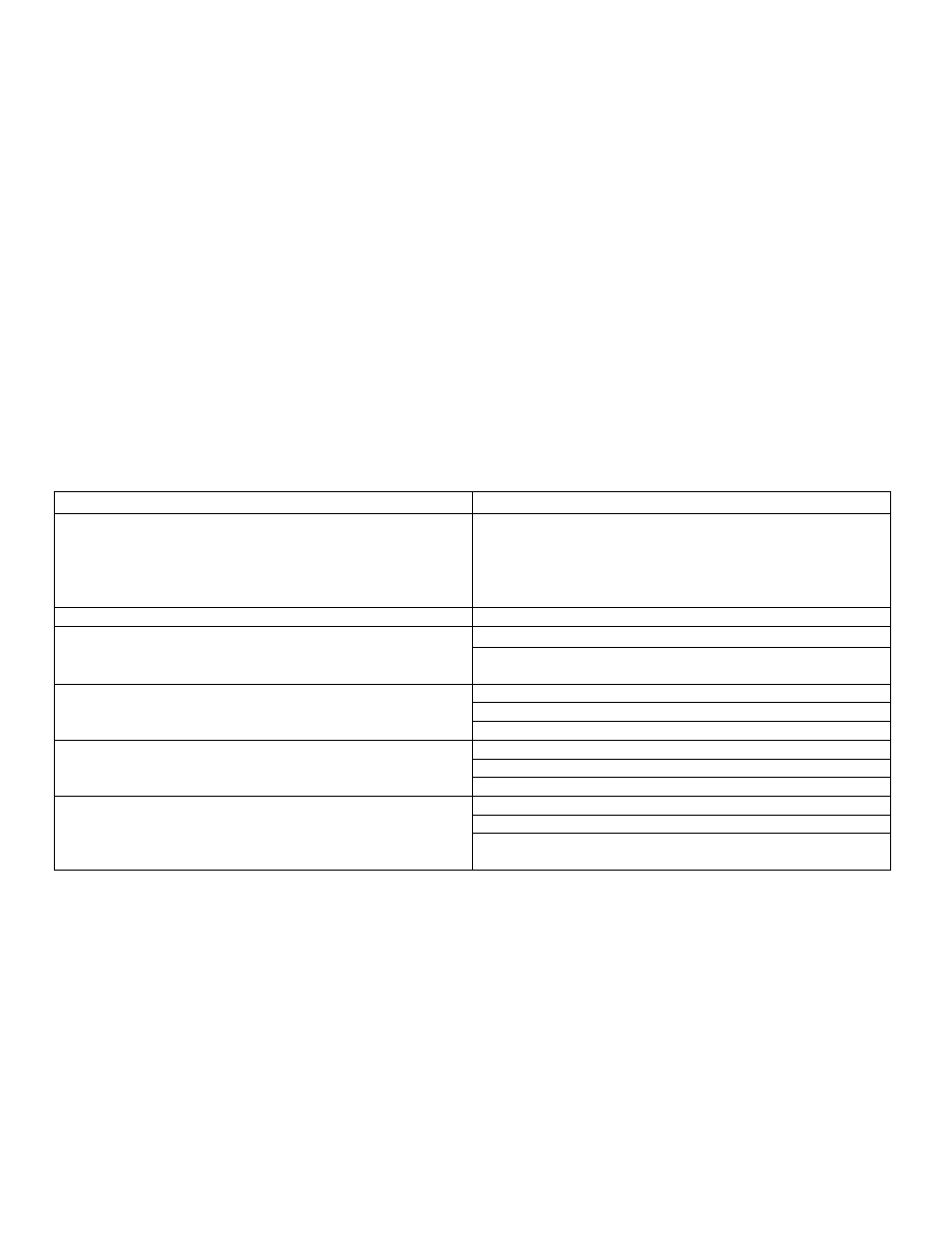

Troubleshooting Guide

Problem

Probable Cause

Pump Head Leakage

Mechanical Seal Wear; replace Mechanical Seal

Leakage between pump body, upper cover and/or casing

Damaged O-ring, replace the O-Ring

Low power during output during peak

Overload protector frequently trips during operation

Unstable voltage supply

Pump cavitation

Damaged motor bearing

Odd noise and vibration

Pump and piping not anchored properly

Pump not primed properly

Excessive head requirement from too much piping

Water is not coming out

Check for restrictions in plumbing

Release air from, or reconfigure intake pipe

Clean out clogged impeller

Pump is operating, but not normally

Check motor rotation to verify if pump is operating

properly