Graymills MVP Series Pump OMI User Manual

Page 2

- 2 -

Electrical supply MUST match pump’s name plate

specifications. Incorrect voltage can cause fire

and/or damage to the motor and voids warranty.

Motor overload protection standard on three-phase

motors.

Use only stranded copper wire to motor and

ground. The ground wire MUST be at least as

large as the wire to the motor. Wires should be

color coded for ease of maintenance.

Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

WARNING

Failure to permanently ground the pump, motor

and controls before connecting to electrical power

can cause shock, burns or death.

ROTATION

Incorrect rotation may cause damage to pump in

and will void the warranty.

Correct rotation is left-hand,

COUNTERCLOCKWISE when viewed from the

motor end.

Rotation can be verified by quickly energizing the

pump for an instant with a quick on/off motion.

To reverse three phase motor rotation interchange

any two power supply leads.

PIPING

Piping should be no smaller than the pump

discharge. Piping should be kept as short as

possible, avoiding unnecessary fittings to minimize

friction losses.

All piping MUST be independently supported and

MUST NOT place any piping loads on the pump. It

should “line up” naturally.

All joints MUST be airtight. Use 3 - 4 wraps of

Teflon™ tape to seal threaded connections.

CAUTION

Never draw piping into place by forcing the pump

discharge connections.

INSTALLATION

WARNING

Multi-stage pumps produce considerable shut-off

pressure. Hoses and associated plumbing used with

these pumps should be rated for a minimum working

pressure of 350 PSI. Failure to heed this warning could

result in ruptured lines and possible injury to personnel.

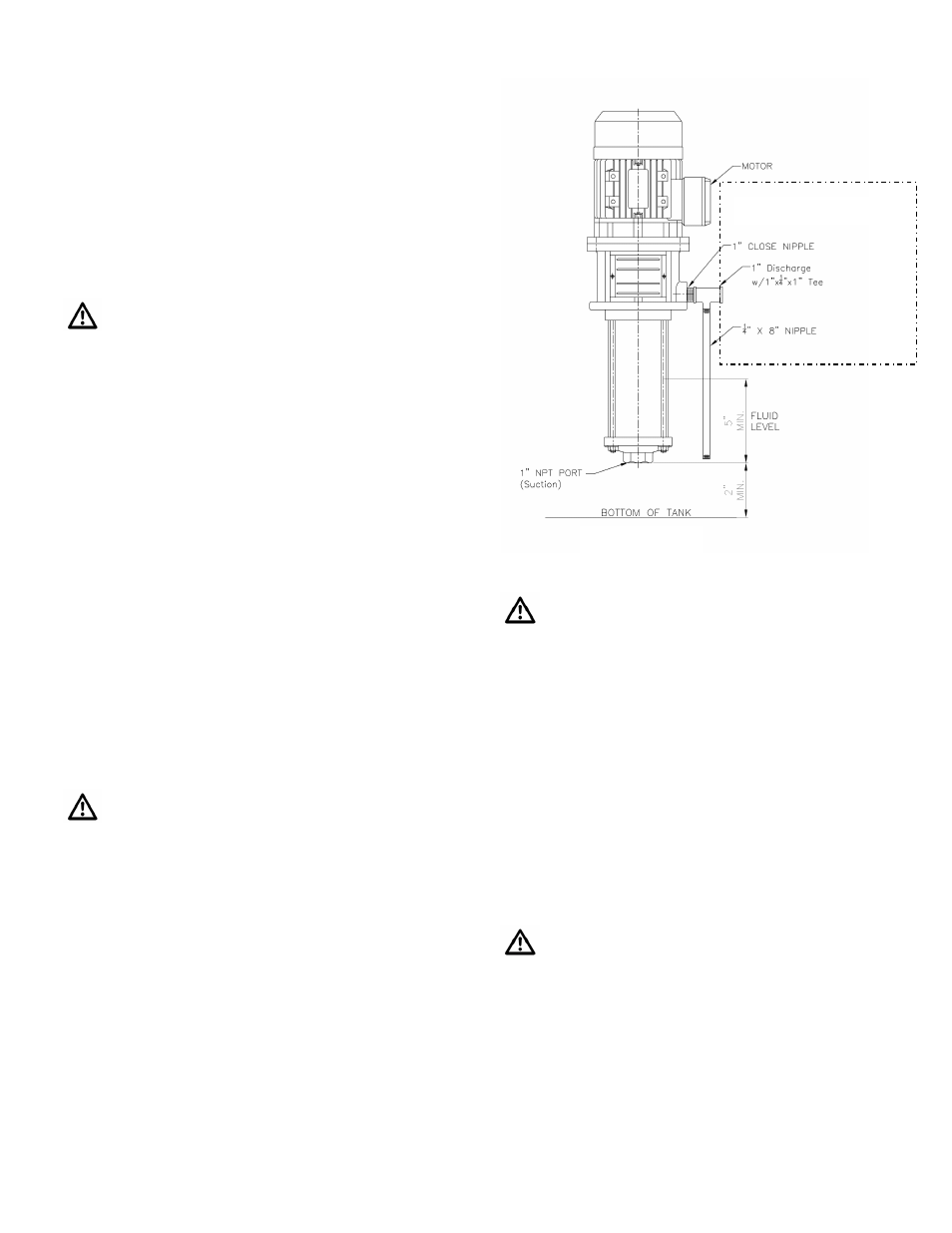

Minimum and maximum liquid levels must be

maintained for proper pump operation.

See Figure 1.

Allow adequate space for servicing and ventilation.

Protect from freezing and flooding

.

The pump must be installed in a ventilated area,

and the ambient temperature must not exceed 40

0

C (104

0

F)

Before installation, verify that motor and pump are

rotating well by rotating the motor fan.

WARNING

Graymills recommends the use of an inlet strainer

to minimize the size and amount of debris that

enters the pump. Contamination drawn into the

pump can cause internal damage and is not

covered under warranty. Consult factory for

recommendations as to the appropriate size and

type of strainer to use.

Figure 1

Bypass Kit (included)