Performance chart – pumps with teflon diaphragms – Graymills DDP .375' Pump User Manual

Page 13

29

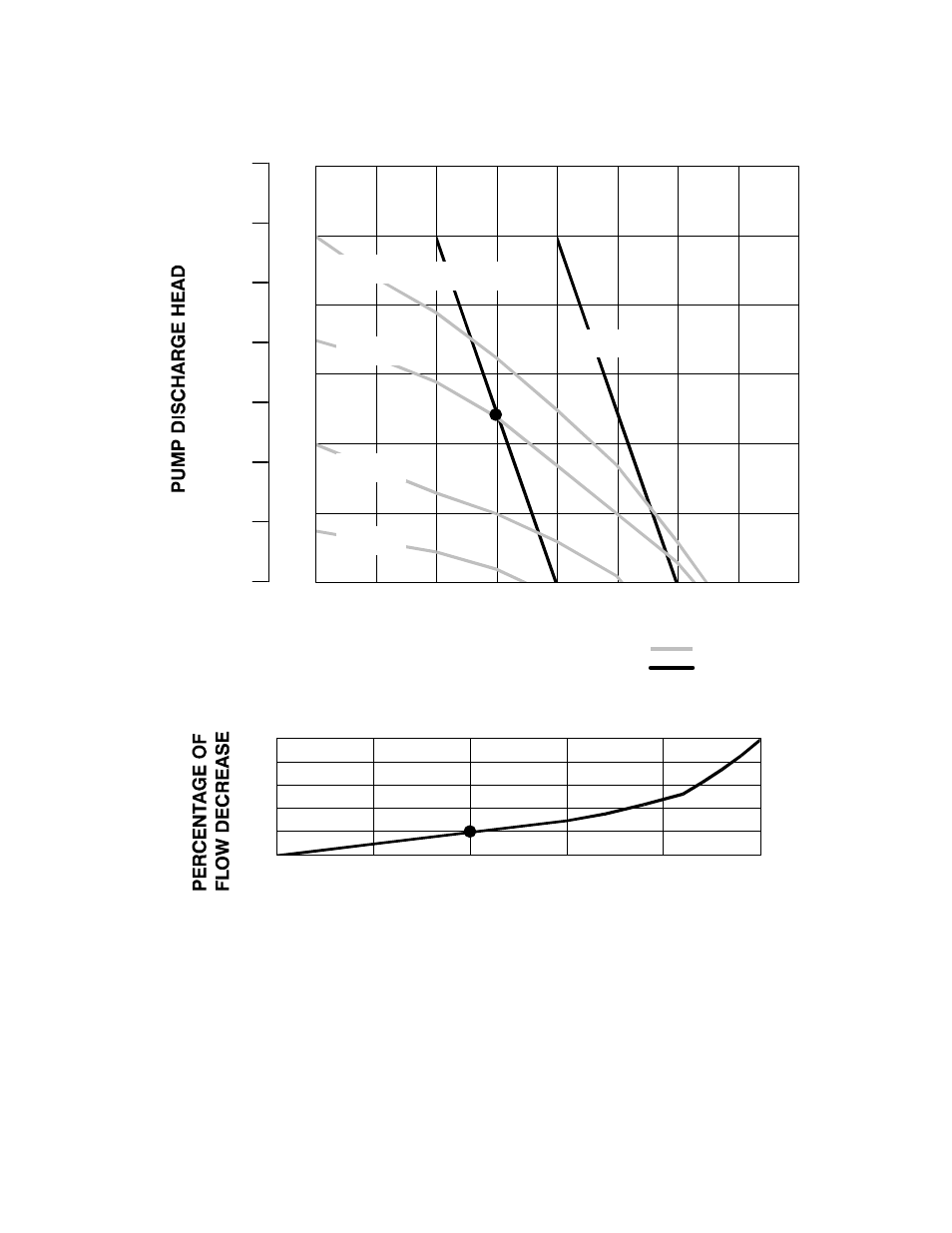

Performance Chart – pumps with Teflon Diaphragms

0

20

40

60

80

100

120

0

1

2

3

4

5

6

7

8

TEST CONDITIONS

Pump tested in water with inlet submerged.

(7.6)

(15.2)

(22.7)

(30.3)

(2.8)

(1.4)

(4.2)

KEY

FLUID PRESSURE AND FLOW

SCFM AIR CONSUMPTION

100 psi air

(7 bar)

Example of Finding Pump Air Consumption and Air Pressure at a Specific Fluid Deliv-

ery and Discharge Head: To supply 3 gpm (11.4 liters) fluid flow (horizontal scale) at 50 psi

(3.5 bar) discharge head pressure (vertical scale) requires 3 scfm (.084 m

#

/min) air con-

sumption at 70 psi (4.9 bar) inlet air pressure.

FLUID FLOW GPM (lpm)

70 psi air

(4.9 bar)

40 psi air

(2.8 bar)

5 scfm

(0.14 m

#

/min)

psi

(bar)

feet

(meters)

280

(85.3)

240

(73.2)

200

(61.0)

160

(48.8)

120

(36.6)

80

(24.4)

40

(12.2)

0

0

20

40

60

80

100

0

5

10

15

20

25

PUMPING RATE DECREASE AT DIFFERENT SUCTION LIFTS

SUCTION LIFT IN FEET (METERS)

(1.52)

(3.05)

(4.57)

(6.1)

(7.62)

EXAMPLE: At a suction lift of 10 ft (3.05 m), the pump flow rate will be decreased by 20 percent.

(5.6)

(7.0)

(8.4)

20 psi air

(1.4 bar)

3 scfm

(.084 m

#

/min)

(3.8)

(11.4)

(19.0)

(26.5)