Dock Edge + Stationary Dock User Manual

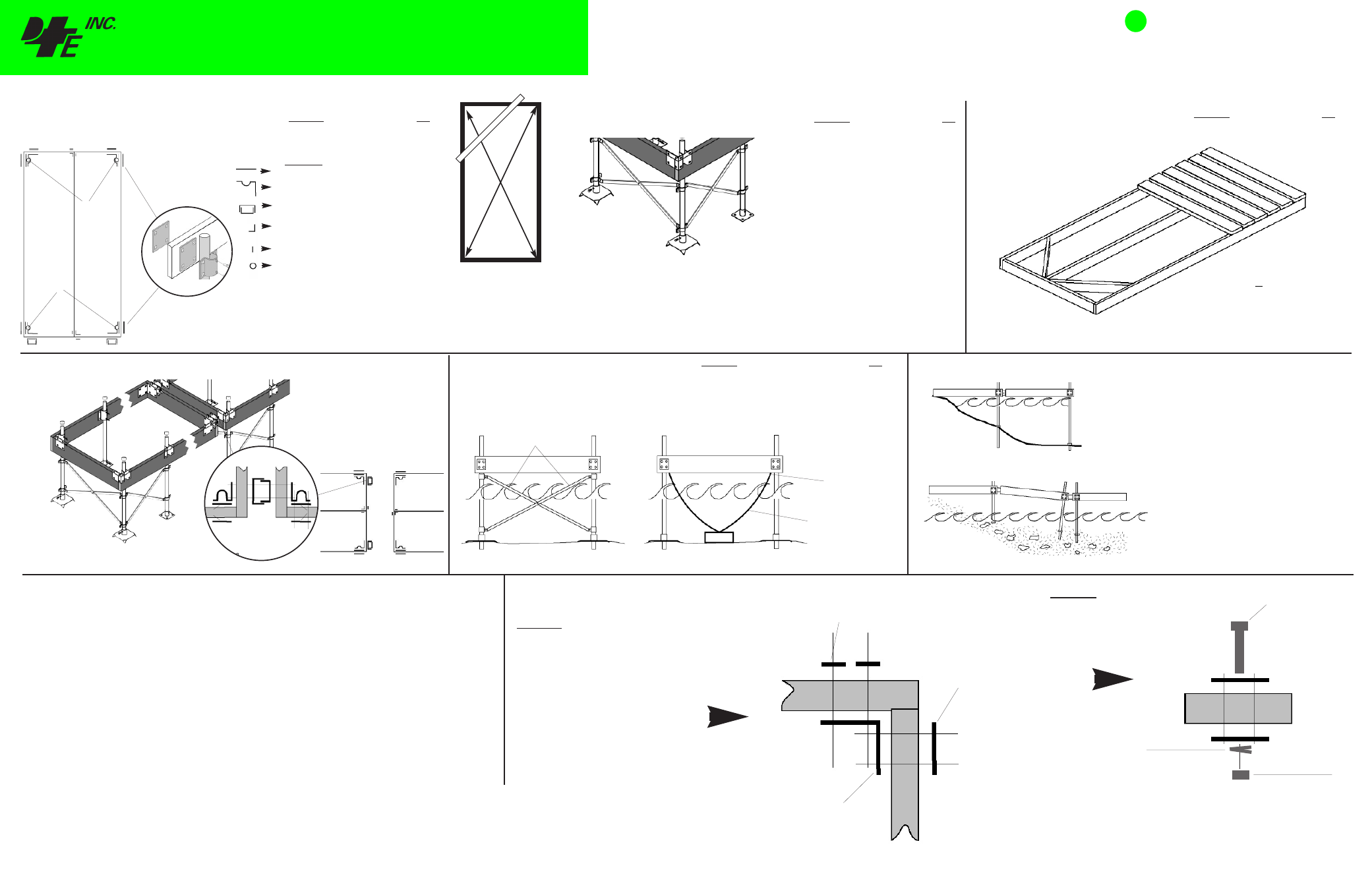

How to guide to guide, Stationary dock hardware, How to build a 4’ x 8’ stationary dock

STATIONARY DOCK HARDWARE

HOW

HOW

TO GUIDE

TO GUIDE

USE GREEN LABELLED OR GREEN DOT COMPONENTS

FOR STATIONARY DOCK CONSTRUCTION

LUMBER

Description

QTY

A - Main dock frame

2” x 8” x 96”

2

B - Center truss:

2” x 8” x 92

3/4

”

1

C - End Cap:

2” x 8” x 69”

2

HARDWARE

D - Backer Plate

87-122-F

10

E - Corner Leg Holder

86-100-F

4

F - Hinge Connector*

86-103-F

2

G - Joist Corner

95-122-F

2

H - Washer Plate

99-006-F

4

I - Leg Pipe, 6’8”

93-168-F

4

Hardware Fastener Kit

85-150-F

5

* Required if affixing dock sections or a ramp together.

1

Assemble main framework

Drill holes for 87-122-F

HOW TO BUILD A 4’ x 8’ Stationary Dock

Description

QTY

Note: Several options and combinations

available for stabilizing a stationary

dock structure

O - Leg Brace Set

89-101-F

6

M - Corner Leg Brace Holder 87-107-F

4

N - Side Leg Brace holder

93-105-F

4

Q - Bottom Pad

94-102-F

4

or

P - Base Plate

86-102-F

4

2

Reinforcing the leg pipes and choosing a leg

pipe base for bottom conditions

3

A

H

G

G

F

D

D

D

D

D

E

E

E

E

J

A

B

C

C

Assemble decking and connector

hinges. (hinges if attaching to

another dock structure or shore

ramp

SSTTA

ATTIIO

ON

NA

AR

RY

Y D

DO

OC

CK

K

A

AN

NC

CH

HO

OR

RA

AG

GEE

Anchorage

to suit

Description

QTY

S - Chain Retainer

99-013-F

2

H - Washer Plate

99-006-F

4

Galvanized chain:

5/16” x approx

48’

Hardware Fastener Kit

85-150-F

1

Anchorage

Min. 125lb ea.

2

S

S

4

Squaring your Dock Structure

Z

Check the squareness by measuring from corner to

corner of the frame in an “X” pattern as shown. The

measurement should be +/- 1/4” between each other. Lock

the framework into square by temporarily securing a piece

of lumber (Z) across one corner as shown above.

IMPORTANT:

DockEdge+ Inc. assumes no responsibility or liability for the accuracy or representation of the graphic illustrations shown in this hardware guide. These graphic illustrations are not

intended to be architectural drawings, and are not to be substituted for engineered drawings. Each is intended as a guideline ONLY. DockEdge+ Inc. does not warrant the quantities and/ or bill of materials to be

accurate in all uses and applications. Individual dock structures may vary by necessity, preference or design. It may be necessary to vary the amount of materials listed in this guide depending on dock size,

material usage, necessity and/ or the severity of the conditions to which the dock structure is subjected to. All graphic illustrations are based on the use of conventional framework of 2” x 6” lumber and decking

lumber. Freeboard may be adjusted by using 2”x8” or 2”x10” lumber. Substitutions in lumber and hardware placement may effect floatation.

Printed in Canada

020711

-

Electric Drill

-

3/16” drill bit

-

3/8” drill bit or auger

-

3/8” drive Socket wrench set

-

Wrench set

-

#2 Robertson (square) bit drive for decking screws

-

Pencil

-

Measuring tape

-

2-1/2” hole saw (not required if mounting leg pipes on outer dock face)

Tools Required for the average Dock Build

(excludes sizing/ cutting of structural wood members)

NOTE: consideration should be given to the

type of bottom the dock will be resting on.

Bottom Pads, 94-102-F are larger than the

Base Plate 86-102-F and therefore better for

soft or sandy bottoms where the dock structure

requires a more stable footing. Alternatively, if

necessary, the base plate may be fastened to a

concrete slab or footing if for additional

stability or in areas of strong currents or wave

action.

H

H

I

I

H

O

O

O

N

N

P

Q

Q

O

M

M

M

M

Always use a backer plate

87-122-F on both sides of the

framework when attaching leg

pipe holders. Optional side leg

holders 86-101-F shown

Description

QTY

- Decking:

2” x 6” x 72”

16

R - Decking Screws:

#10 x 3”

96

Connecting Dock Sections

When attaching dock sections, leg

braces should always be used on the

leading edge of each dock section for

stability.

Where dock sections are attached, the

outer backer plate 87-122-F used for

the corner leg holder may simply be

replaced by the hinge connector

86-103-F as shown.

IMPORTANT TIPS

Always use washer plates

(99-006-F), backer plate

(87-122-F) or mating hardware

components together.

Framework of the dock

structure should be

sandwiched between hardware

pieces at all joint locations as

shown. (sample only, other

configurations possible)

99-006-F

Washer Plate

Always use a lock

washer with each

carriage bolt usage

to prevent bolts

loosening over

time.

Carriage

Bolt

Nut

• Use hinge 86-103-F between dock

segments.

• Allow leg pipes to protrude below the bottom

pads by approximately 12” so they will

become embedded in the lake bed.

• Adjust leg pipe holders on leg pipes to level

dock segments before tightening.

• Use hinge 86-103-F between dock

segments.

• Allow the dock segment with the highest

drop in elevation to act as a ramp to a

maximum of 15º angle.

• Adjust leg pipe holders on leg pipes to

sufficient contact with lake bed. Tighten leg

holders.

Wood Frame

Lock Washer

87-122-F

Backer Plate

86-104-F

Inside Corner

Wood Frame

UNEVEN SHORELINE INSTALLATION

GRADED SHORELINE INSTALLATION

Backer Plates not

used with hinges

Galvanized Chain

5/16” to 3/8”

Drive leg pipes no less than 12” into lake bed,

24” if dock to be used for a boat mooring.

Leg Braces

Chain Retainer

Shown with optional corner braces added for

extra rigidity.

F

D

D

E

E

F

®