Warning danger warning, Code symbols – Chemglass CG-2025 User Manual

Page 2

Read air motor label to check that

motor has been designed for use

in a hazardous application:

• Hazardous zone

• Hazardous category

• Equipment group

• Temperature class

• Maximum surface temperatures

Example:

Model designation: 1UP-NRV-10

Year manufactured: 2003

Gast Mfg. Corp.

II 2GD c T5 *

Benton Harbor, MI USA

Telephone: 269.926.6171

* Legend:

II Equipment group II

2 Equipment category 2

G Gas atmospheres

D Dust atmospheres

c Constructional safety

T5 Max. surface temp. 212ºF/100ºC

Your safety and the safety of others

is extremely important.

We have provided many important safety messages

in this manual and on your product. Always read

and obey all safety messages.

This is the safety alert symbol. This symbol

alerts you to hazards that can kill or hurt you and

others. The safety alert symbol and the words

“DANGER” and “WARNING” will precede all safety

messages. These words mean:

You will be killed or seriously injured if you don’t

follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you

what can happen if the safety instructions are not

followed.

Correct installation is your responsibility. Make sure

you have the proper installation conditions.

INSTALLATION

WARNING

DANGER

WARNING

Injury Hazard

Install proper guards around output shaft as

needed.

Air stream from product may contain solid or liquid

materials that can result in eye or skin damage.

Wear eye protection when installing this product.

Failure to follow these instructions can result in

serious injury or property damage.

2

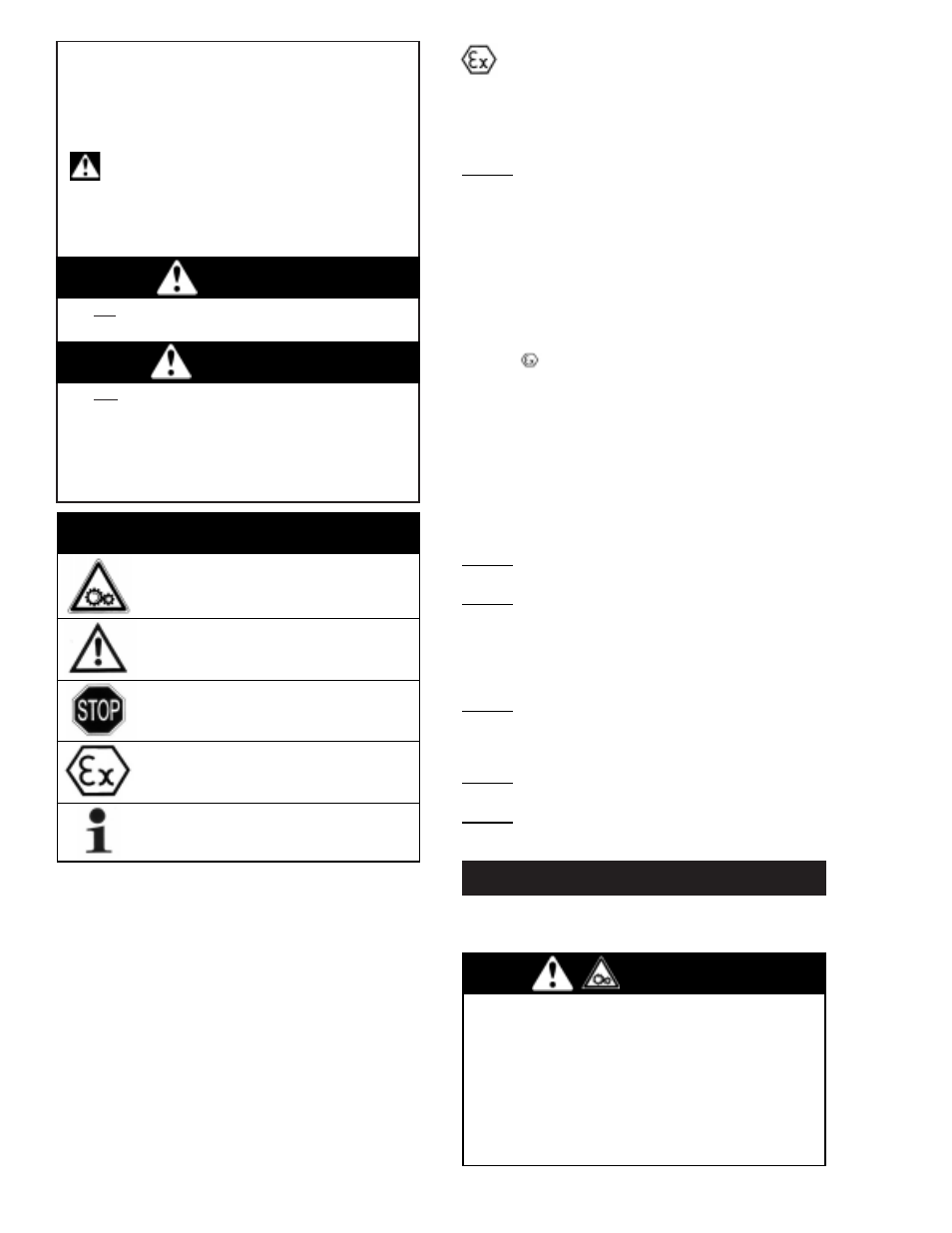

CODE SYMBOLS

Hazard.

Possible consequences: death or

severe injuries.

Hazardous situation.

Possible

consequences: slight or mild injuries.

Dangerous situation.

Possible

consequences: damage to the drive or the

environment.

Important instructions on protection

against explosion.

Application tips and useful

information.

Improper environment, installation and operation

can result in severe personal injury and/or damage

to property.

Qualified personnel must perform all work to

assemble, install, operate, maintain and repair air

motor.

Qualified personnel must follow:

• These instructions and the warning and information

labels on the motor.

• All other drive configuration documents, startup

instructions and circuit diagrams.

• The system specific legal regulations and

requirements.

• The current applicable national and regional

specifications regarding explosion protection,

safety and accident prevention.

Complete the following checklist prior to

starting installation in a hazardous area. All

actions must be completed in accordance with

ATEX 100a.

Check the site environment for potentially

explosive oils, acids, gases, vapors or radiation

Check the ambient temperature of the site and

the ability to maintain proper ambient

temperature.

Ambient range:

Normal conditions: 34ºF/1ºC to 250ºF/121ºC

Hazardous conditions: 34ºF/1ºC to 104ºF/40ºC

Check the site to make sure that the air motor

will be adequately ventilated and that there is

no external heat input (e.g. couplings). The

cooling air may not exceed 104ºF/40ºC.

Check that products to be driven by the air

motor meet ATEX approval.

Check that the air motor is not damaged.

Checklist for installation in hazardous areas: