Chemglass CG-2025 User Manual

Page 13

13

General Information:

The product nameplate specifies all information required

when ordering parts or requests for information. The

type of lubricant required for unit is also specified on the

nameplate.

STANDARD & WORM GEAR REDUCERS - OPERATING AND MAINTENANCE INSTRUCTIONS

Product Use Criteria:

• All worm gear reducers require that the air motor be

mounted so that the inlet and exhaust ports are at a

90

º

angle to the centerline of the reducer output shaft.

• Gear reducers are NOT self-locking. If a brake is

required for safety, as in the case of air pressure failure,

etc., contact your Gast Distributor/Representative.

• Worm gear reducers are shipped with a plug in the top

pipe plug. The plug must be removed and the breather

plug installed for proper operation.

• Operating an air motor without venting will create

internal pressure build-up which can damage the

internal parts of the gear reducer.

• Check the oil level in units which have been stored or

not operated for a period of time.

• Gear motors require proper lubrication. Insufficient oil

level can cause loss of performance, damage or failure

of the gear reducer.

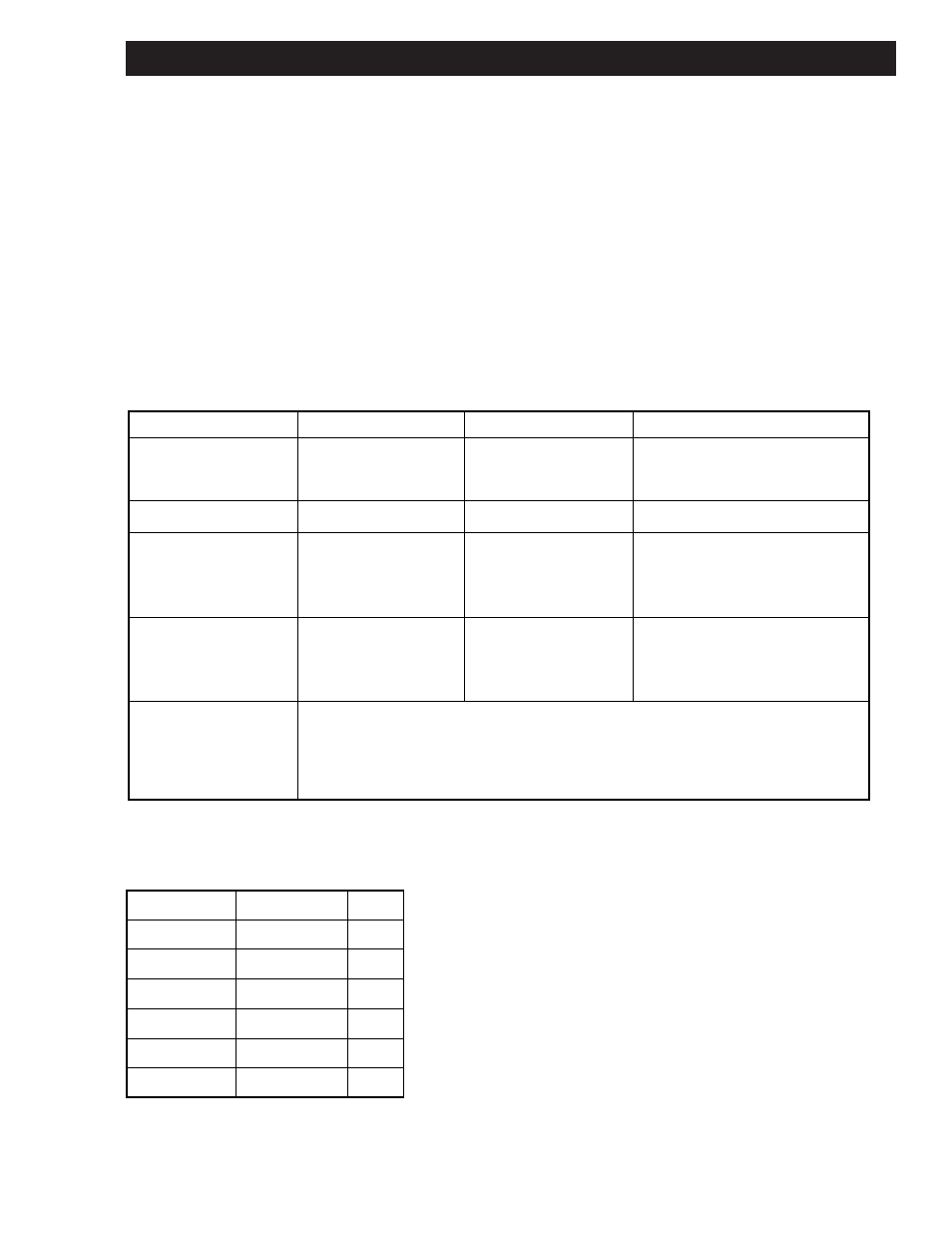

Model

GR11

GR20

GR25

Speed Range

33.3 to 400 RPM

30 to 300 RPM

20 to 200 RPM

(Reducer Output Shaft)

Gear Reduction

15:1

10:1

15:1

Maximum Allowable

100 lbs/45,4 kg

200 lbs/90,8 kg @300

250 lbs/113,5 kg at 200

End Thrust With

RPM to 800 lbs/363,2 kg

RPM to 800 lbs/363,2 kg

Zero Overhung Load.

at 30 RPM

at 20 RPM

(Reducer Output Shaft)

Maximum Allowable

100 lbs/45,4 kg at 333

200 lbs/90,8 kg at 300

200 lbs/90,8 kg at 200

Overhung Load With

RPM to 200 lbs/90,8 kg

RPM to 600 lbs/272,4 kg

RPM to 600 lbs/272,4 kg

Zero End Thrust.

at 33.3 RPM

at 30 RPM

at 20 RPM

(Reducer Output Shaft)

Lubrication

Use a 300 ssu at 100˚F/38˚C turbine quality lubricant – Gast #AG292A, Gulf

Harmony 53, Shell Tellus 33, Socony DTE heavy medium or Humble Nuto 53.

For horizontal operation, remove both plugs and add oil to top hole until

other hole overflows.

For vertical operation, fill to overflow point of upper most hole.

Gear Reducer Specifications

Worm Gear Reducer Series A-F

Gear Reducer Specifications

All output shafts are in the standard location.

Model

Air Motor

Ratio

AG803

4AM

20:1

AG805

4AM

40:1

AG807

4AM

60:1

AG809

6AM

10:1

AG811

6AM

20:1

AG816

8AM

20:1

Change output shaft direction

1.

Remove drain plug and drain oil from unit.

2.

Remove end cover and seal cage cap screws.

While supporting output shaft, remove end cover

and shims from unit. Keep shims with cover.

3.

Remove output shaft and seal cage together from

extension side. Keep shims with seal cage.

4.

Insert seal cage, shims and sub-assembly into

housing from the side opposite from which they

were removed.

5.

Insert seal cage cap screws and tighten with light

pressure.

6.

Assemble end cover with shims. Insert end cover

cap screws and tighten with light pressure.

7.

Turn high speed shaft in both directions to check

that gear train is running freely.

8.

Cross-tighten seal cage and end cover cap

screws.

Service, Parts or Repair

For service, parts or repair of the worm gear reducer,

contact the manufacturer listed on the nameplate.