Making adjustments to your mobile base, Hydraulic jack maintenance – SawStop Industrial Mobile Base User Manual

Page 5

● Keep the jack clean and free from saw dust.

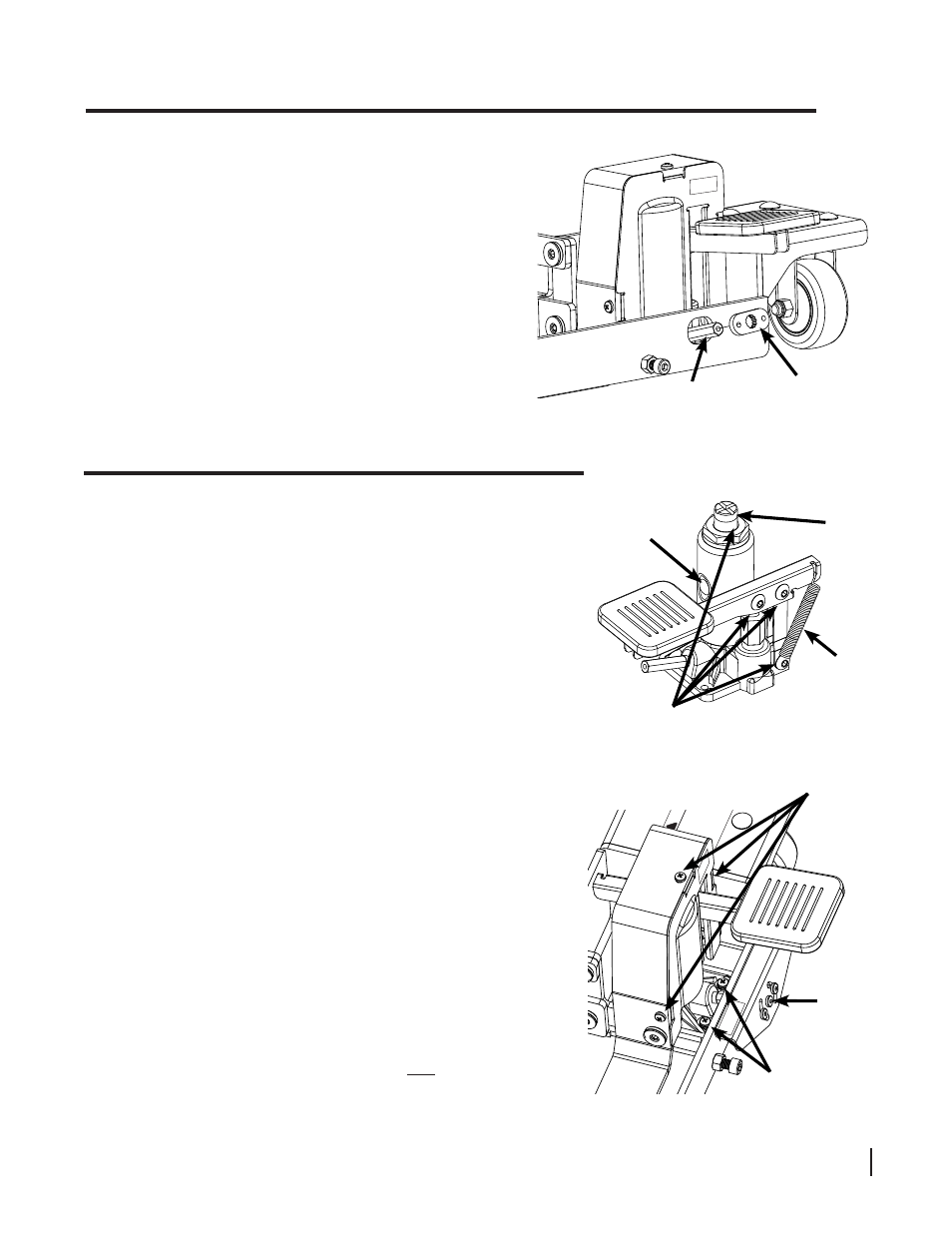

● Use SAE 30 oil to periodically lubricate the points shown in Fig. 7.

To access the lubrication points, remove the three jack cover screws

using a Philips head screwdriver (see Fig. 8) and then remove the

jack cover.

● The jack must have the proper amount of hydraulic oil to function

correctly. If the jack is not lifting or maintaining the weight of the saw

properly you may need to remove the jack from the mobile base and

add hydraulic oil as follows:

1. Make sure the saw is lowered to the ground. Remove the center

release lever screw shown in Fig. 8 using a 3 mm hex key.

Remove the three jack cover screws, and the two jack mounting

screws using a Philips screwdriver.

2. Slide the release lever (with the attached release adjustment

plate) off the hexagonal shaft. Remove the jack cover.

3. Place a flat head screwdriver on top of the jack lifting piston (see

Fig 7) and push the piston down as far as possible. Remove

the jack by tilting the top forward and sliding the hexagonal

shaft back out of the hole in the mobile base frame.

4. Once the jack is removed, place it in an upright position

and remove the extension spring. Completely depress the

foot pedal. Remove the rubber filler plug shown in Fig. 7 by

pulling it out with your fingers or prying it out with a flat head

screwdriver. Add hydraulic jack oil so that the oil level is just

to the bottom of the filler hole. Use only hydraulic jack oil.

Replace the filler plug and extension spring and reinstall the

jack by reversing the steps set forth above.

6. After removing the release lever, you will see a release

adjustment plate (see Fig. 6). That plate has a hole with

12 notches. To decrease the speed at which the saw

lowers, slide the adjustment plate off the hexagonal shaft

and rotate the plate counter-clockwise one notch (

1

⁄

12th

of

a turn) before sliding it back onto the shaft. To increase the

speed at which the saw lowers, slide the adjustment plate

off the hexagonal shaft and rotate the plate clockwise one

notch (

1

⁄

12th

of a turn) before sliding it back onto the shaft.

7. Reinstall the release lever on the hexagonal shaft, and

screw in and fully tighten the three release lever screws.

Test the speed at which the saw lowers and repeat these

steps if necessary.

SawStop Industrial Mobile Base 4

Making Adjustments to Your Mobile Base

Fig. 6

Raise

Hydraulic Jack Maintenance

Fig. 8

place fingers, toes or other

t ts under the mobile base.

s use the saw and the mobile

b a level surface.

t continue to step on the foot p

c the upper limit is reached.

the saw before use. Never use

t when it is raised off the floor

.

!

W

AR

NIN

G

Raise

Lower

jack cover

screws

jack mounting

screws

center

release

lever

screw

release

adjustment

plate

Fig. 7

lubrication

points

filler

plug

lifting

piston

extension

spring

hexagonal shaft