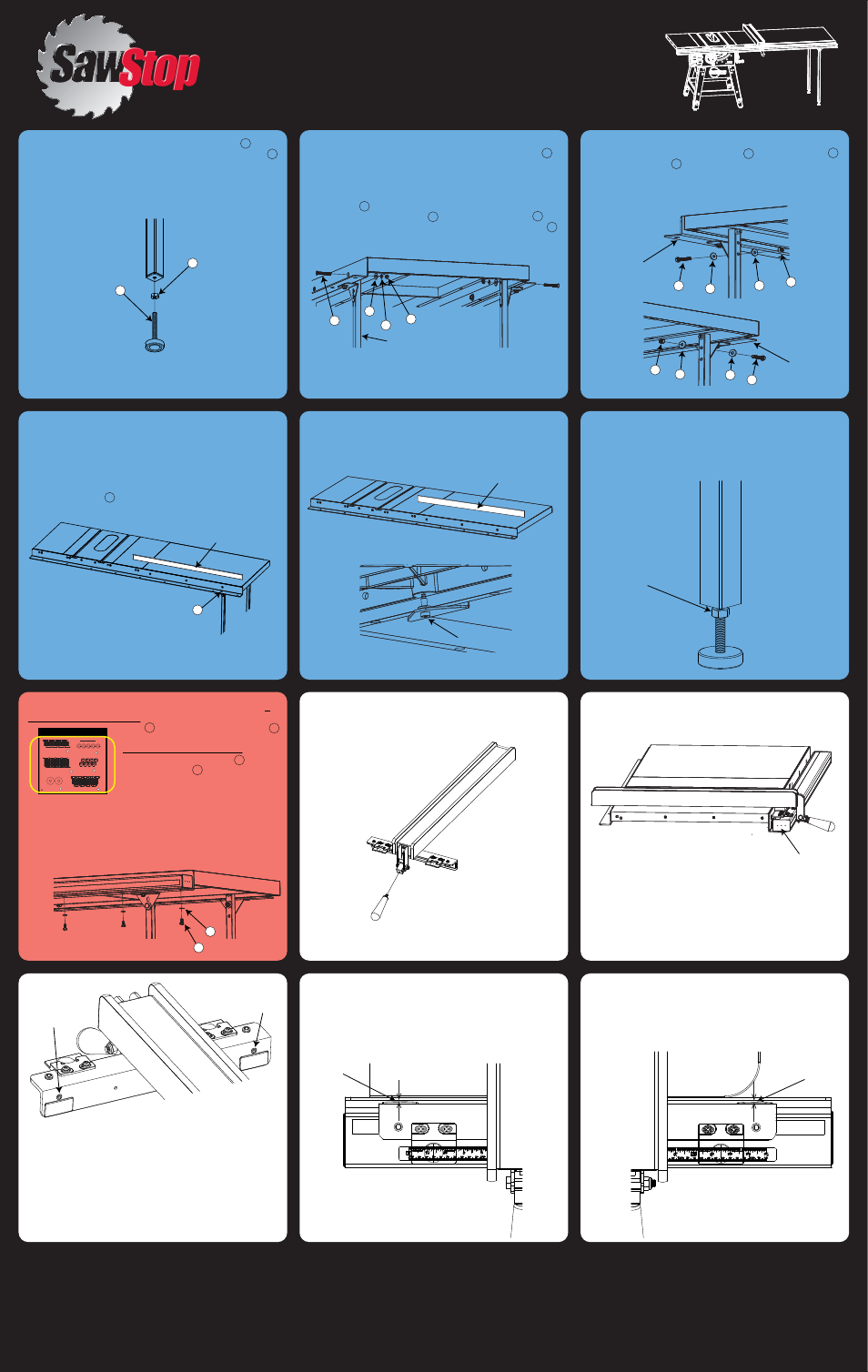

Sawstop, Contractor saw, Installing your t-glide fence system on your – SawStop T-Glide User Manual

Page 2: Other accessories

SawStop Service

Department

503-582-9934

www.sawstop.com

© SawStop, LLC

17

19

16

14

12

21

18

11

13

15

parallelism

adjustment

screw

parallelism

adjustment

screw

• Press down on the fence handle to clamp the fence to the front

tube. If the fence does not clamp tightly enough to hold its

position against a moderate amount of force, you can increase

the clamping pressure by turning both parallelism adjustment

screws clockwise using a 5 mm hex key. Those screws are

located in the vertical edge of the fence cross-bracket.

Alternatively, if too much force is required to push the

fence handle down to clamp the fence to the front tube,

you can reduce the clamping pressure by turning both

parallelism adjustment screws counter-clockwise.

Congratulations, your fence system is now

installed and ready to use.

Other Accessories

There are optional accessories

available for your saw, such as a

mobile base or an out-feed table.

See your saw Owner’s Manual

for more information.

gap

• Once the fence is tightly clamped to the front tube, move the

left end of the tube back toward the saw until there is only a

small gap (approximately 1/16 inch) between the front rail and

the rear of the fence. Tighten the left-most M8 x 16 hex head bolt

that holds the tube to the front rail using a 13 mm wrench.

gap

• Next, move the fence to the right end of the tube, repeat the

above process to position the tube, and tighten the right-most

screw. Once both ends of the tube are adjusted correctly, tighten

the remaining M8 x 16 hex head bolts to mount the front tube

to the front rail. The fence should now slide smoothly along the

front tube without binding and without excessive play.

Please refer to your T-Glide Fence System - Professional Series II Owner’s Manual

for information on how to correctly use and adjust your fence system.

adjust the position of

the foot and tighten

the hex nut

• Turn the foot on the bottom of each support leg to adjust its

position until it is in solid contact with the ground. Once the foot

is in contact with the ground, fully tighten the hex nut against the

bottom of the leg using a 13 mm wrench.

• Locate the fence and the red fence handle. Thread the handle

into the cam lock on the front of the fence.

SawStop

thread the handle into

the cam lock

• Locate the two support legs and remove the two feet from

the T-Glide Table Hardware Pack along with two M8 hex nuts .

Thread an M8 hex nut onto the threaded shaft of each foot so

that the nut is close to the rubber base, and then thread the foot

into the bottom of the support leg as far as possible.

19

21

21

19

6

4

• The holes in the bottom of the front rail are oversized to allow

you to adjust the position of the tube on the rail. To set the tube

in the correct position, first pull the front tube away

from the table as far as possible. Next, place your

fence down on the tube near the left end.

• Use a straight-edge to level the front edge of the extension

table to the saw table. You may have to pull up or push down on

the extension table to level it. Once the front edge of the extension

table is level, use a 5 mm hex key and a 13 mm wrench to fully

tighten the nuts on the bolts along the front rail. Repeat the

process to level the rear edge of the extension table. Also fully

tighten the bolts that attach the leg support brackets to the front

and rear rails (bolts in step 8).

16

• Attach each support leg to the corresponding leg support

bracket with an M10 x 40 hex head bolt , two M10 washers ,

and an M10 lock nut and fully tighten the bolts using two

17 mm wrenches. Note that the leg support brackets align with

different holes in the front and rear legs because the brackets

are at different elevations.

25

23

24

• Place the straight-edge lengthwise across the middle of the

table (see Fig. 15a) and level the middle of the extension table

by turning the screw in the adjustment bracket with a 5 mm hex

key (see Fig. 15b).

Fig. 15b

22

17

18

19

support leg

• The support legs attach to the outer ends of the rails and

extension table with M8 x 65 countersunk socket head bolts .

Align the top hole in one support leg with the outermost hole in

the front rail, and the top hole in the second support leg with

the outermost hole in the back rail. Make sure the legs are

positioned against the inside of the extension table. Insert an

M8 x 65 bolt through the holes in the rails, extension table

and legs. Place an M8 washer and an M8 lock washer on

the threaded end of each bolt and then thread an M8 hex nut

onto each bolt. Hand tighten the nuts; do not fully tighten them.

17

22

18

19

22

rear rail

25

24

23

24

front rail

23

24

24

25

Fig. 15a

22

straight-edge

®

Contractor Saw

SawStop

Installing Your T-Glide Fence System on Your

TM

20

• Locate the front tube and the T-Glide Rails Hardware Pack. If

you have a 36” fence system, remove seven M8 x 16 hex head

bolts and seven M8 lock washers

from the T-Glide Rails Hardware Pack.

If you have a 52” fence system, remove

nine M8 x 16 hex head bolts and nine

M8 lock washers from the T-Glide

Rails Hardware Pack. Position the tube

on the front rail with the rulers facing up

and the 12-inch ruler on the left. The powder coated surfaces of

the tube and rail can be slick, so be careful that the tube does

not fall off the rail. Align the holes in the rail with the holes in the

bottom of the tube. Place an M8 lock washer on each M8 x 16

hex head bolt and insert the bolts through the rail and into the

threaded holes in the bottom of the tube. Hand tighten the bolts;

do not fully tighten them.

6

4

6

4

front tube

0

15

30

45

SawStop

10” Contractor Saw

SA

WSTOP

adjustment screw

T-Glide Rails Hardware Pack

2

Countersunk Socket Head Bolts,

M8 x 25 (8)

Washers,

M8 (8)

3

Lock Washers,

M8 (17)

4

II

Professional Series

Countersunk Socket

Head Bolts, M8 x 16 (8)

1

Hex Head Bolts, M8 x 16 (9) 6

Hex Nuts,

M8 (8)

5

F

Fold line

Height = 664 mm

332 mm

straight-edge

16

make sure to tighten the bolts that

attach the leg support brackets to

the front and rear rails